Calcium carbide method polyvinyl chloride mercury-containing wastewater treatment and recycling method and application device thereof

A polyvinyl chloride and wastewater treatment technology, applied in natural water treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as increased power consumption, increased tank voltage, and reduced life of ionic membranes. The effect of high degree of engineering, low operating cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

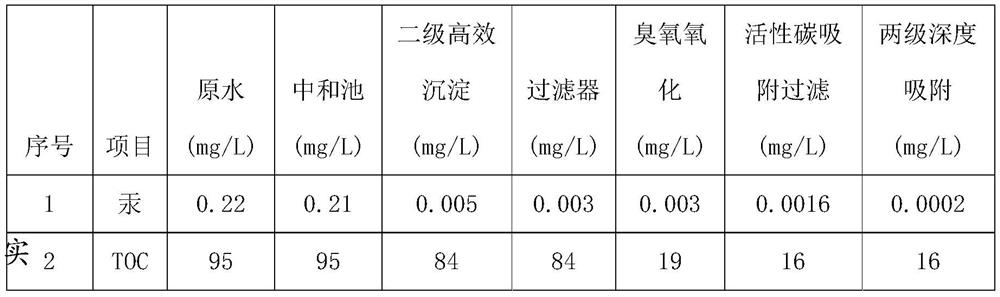

Examples

Embodiment 1

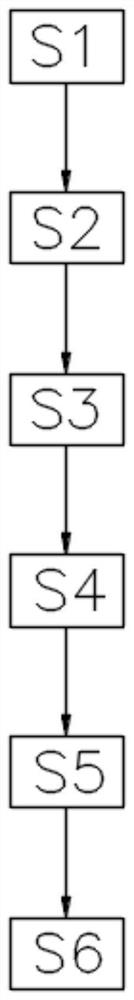

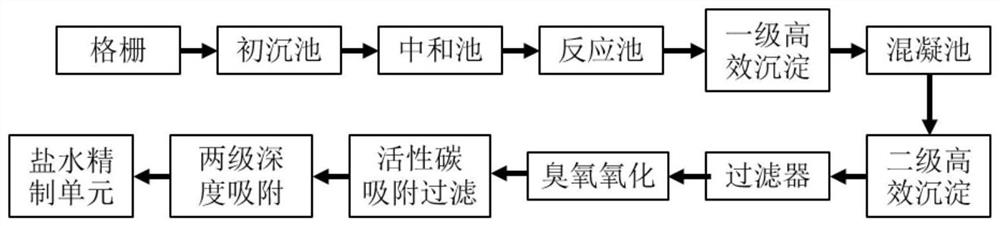

[0045] Such as figure 1 As shown, the first aspect of the present invention provides a kind of calcium carbide process polyvinyl chloride mercury-containing wastewater treatment and recycling method, comprising the steps of:

[0046] S1, pretreating the mercury-containing wastewater, removing impurities and sediments in the water, and obtaining the first mixed solution;

[0047] In this embodiment, the calcium carbide process polyvinyl chloride mercury-containing wastewater is selected for wastewater treatment and recycling. First, the mercury-containing wastewater is pretreated, and the impurities and sediments in the water are removed through the grille and the primary sedimentation tank in turn; the raw water is pretreated through the grille and sedimentation to remove impurities and sediments in the water.

[0048] S2, performing acid-base neutralization adjustment on the first mixed solution to adjust the pH to 7.5-9.5 to obtain a second mixed solution;

[0049] Acid-ba...

Embodiment 2

[0074] The second aspect of the present invention provides an application device for implementing the calcium carbide process polyvinyl chloride mercury-containing wastewater treatment and recycling method described above, including:

[0075] Pretreatment equipment, used for pretreatment of mercury-containing wastewater, including grids and primary sedimentation tanks. Mercury-containing wastewater passes through grids and primary sedimentation tanks in sequence to remove impurities and sediments in the water to obtain the first mixed solution and discharge it into the middle and pool;

[0076] The neutralization tank is used to adjust the acid-base neutralization of the first mixed solution, adjust the pH to 7.5-9.5 to obtain the second mixed solution, and discharge it into the reaction tank;

[0077] A reaction tank, in which mercury remover and sodium sulfide are added, is used to react with the second mixed solution to convert mercury ions into solid mercury, and discharge...

Embodiment 3

[0092] On the basis of Embodiment 2, in this embodiment, the micro-nano ozone bubble generator is preferably used as the ozone oxidation device.

[0093] As an optional embodiment of the present application, optionally, the ozone oxidation equipment is a micro-nano ozone bubble generator, and the diameter of the ozone bubbles is 5-50 μm.

[0094] Micro-nano ozone bubble generator, the diameter of ozone bubbles is 5-50 μm, which can increase the contact area between ozone micro-bubbles and water body, prolong the residence time of ozone in water, and further guarantee the oxidation effect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com