Method for recovering phosphate in sewage by in-situ generation of calcium carbonate microsphere phosphate fertilizer and application of method

A technology of calcium carbonate microspheres and in-situ generation, which is applied in the fields of application, calcium fertilizer, sewage/sludge fertilizer, etc., to save time, positively promote growth, and benefit agricultural growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

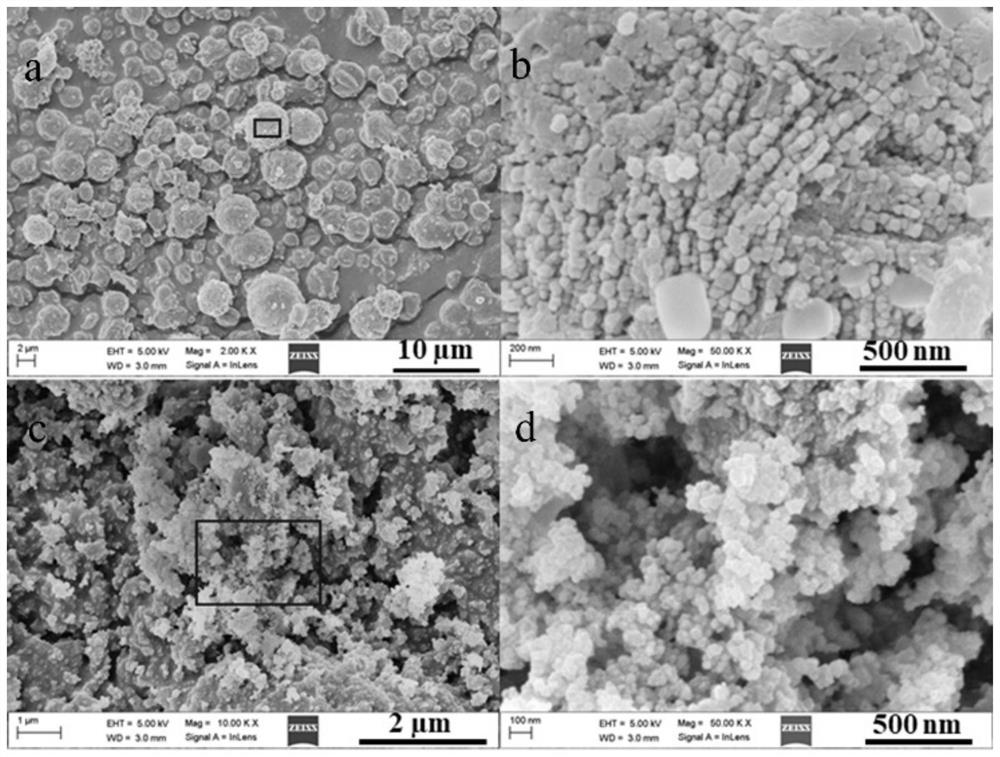

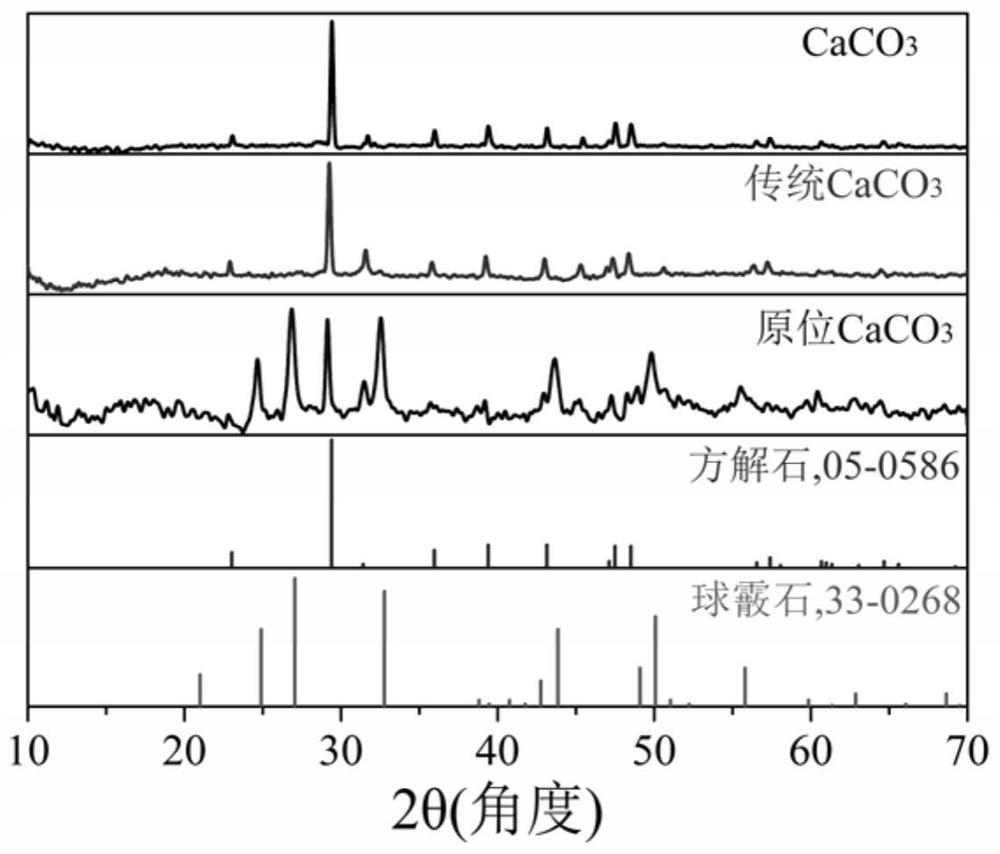

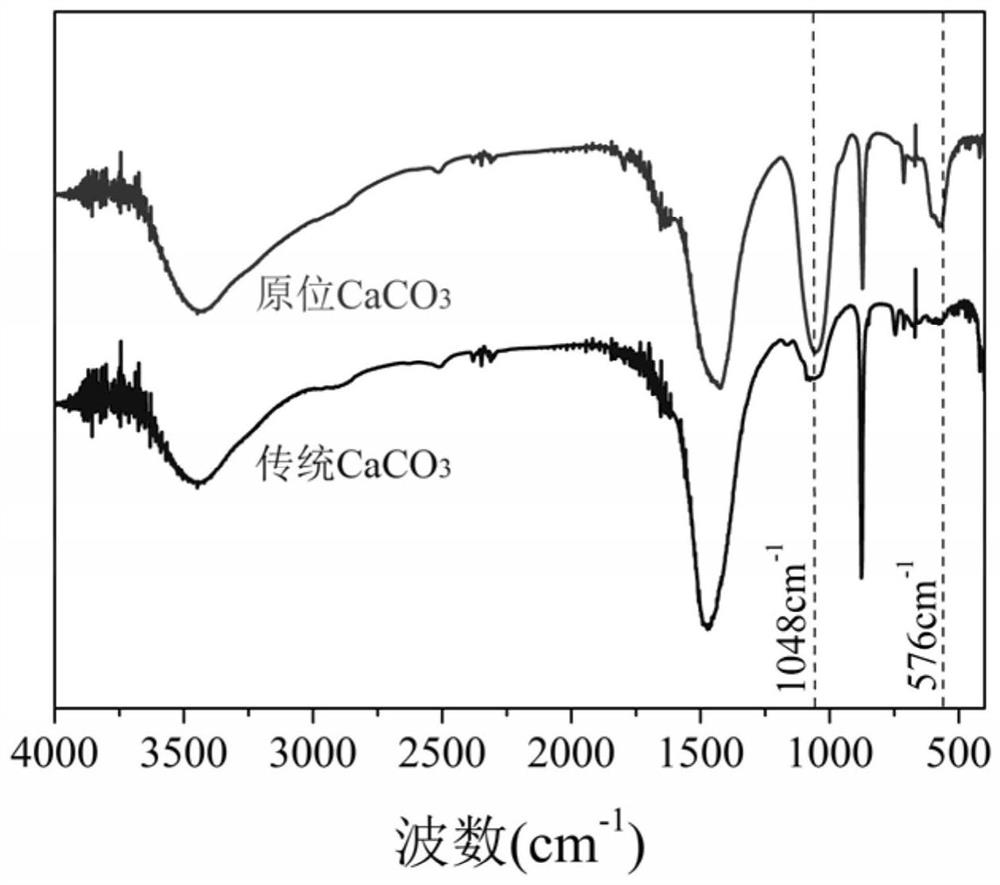

[0042] 1. In situ generation of calcium carbonate microsphere phosphate fertilizer

[0043] By simulating sewage from low concentration (NaH 2 PO 4 Solution, enriching phosphorus element in 10mg-P / L) prepares the method for in-situ generation calcium carbonate microsphere phosphate fertilizer, comprises the steps:

[0044] The preparation concentration is 38.73mg / L sodium dihydrogen phosphate (NaH 2 PO 4 ) solution (total phosphorus calculated as P is 10mg / L) to simulate low-concentration phosphorus-containing water (generally, more studies focus on phosphorus-containing water with phosphorus concentration exceeding 10mg-P / L, and less research on sewage with lower phosphorus concentration , so the sewage with phosphorus concentration ≤ 10mg-P / L is defined as the water body with low concentration of phosphorus). Under normal stirring state, first add calcium chloride (CaCl 2 , 1mol / L) solution until CaCl in the system 2 Concentration is 214.8mg / L, add sodium carbonate (Na...

Embodiment 2

[0054] The phosphorus removal effect of in-situ generation of calcium carbonate microsphere phosphate fertilizer and traditional synthetic calcium carbonate method under different Ca / P molar ratios includes the following steps:

[0055] (1) Phosphorus removal with different Ca / P molar ratios under the method of in-situ generation of calcium carbonate microsphere phosphate fertilizer. Under stirring, add sodium dihydrogen phosphate (NaH 2 PO 4 ) solution (total phosphorus calculated as P is 10mg / L) was successively added CaCl 2 solution until CaCl in the system 2 Concentration is 71.6, 143.2, 179, 214.8, 286.4 and 358mg / L, after reacting for 30min, take a sample to measure phosphorus content, then add Na 2 CO 3 solution until the Na in the system 2 CO 3 The concentrations were 68.4, 136.8, 171, 205.2, 273.6 and 342 mg / L, and the stirring was stopped after continuing the reaction for 30 minutes. Filter the water sample and measure the phosphorus content according to GB118...

Embodiment 3

[0059] Different Ca in Phosphate Fertilizer Method of In-Situ Generation of Calcium Carbonate Microspheres 2+ / CO 3 2- The phosphorus removal effect of molar ratio, comprises the steps:

[0060] With reference to the operating steps of Example 1, under stirring, to volume is 1L, concentration is 38.73mg / L sodium dihydrogen phosphate (NaH 2 PO4) solution (total phosphorus calculated as P is 10mg / L) is added with CaCl 2 solution until CaCl in the system 2 The concentration is 214.8mg / L, and the phosphorus content is measured by sampling, and then Na 2 CO 3 solution until the Na in the system 2 CO 3 Concentrations were 68.4, 102.6, 136.8, 307.8 and 410.4 mg / L, and the reaction was continued for 30 minutes before stirring was stopped. After the reaction, the water sample was filtered to determine the phosphorus content.

[0061] Figure 5 Different Ca in the phosphate fertilizer method that generates calcium carbonate microspheres in situ for embodiment 3 2+ / CO 3 2- ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com