Preparation method of cardanol bio-based polyol and application of cardanol bio-based polyol in flexible package adhesive

A technology of bio-based polyols and cardanol, which is applied in adhesives, adhesive types, sustainable manufacturing/processing, etc., can solve the problems of low polarity, reduce waste, suppress white spots, and improve peel strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: 2000 parts by mass of cardanol, 550-650 parts by mass of hydrogen peroxide, 40-52 parts by mass of formic acid, and 10-22 parts by mass of phosphoric acid are heated to a temperature of 60 ° C, react for 6 h, and then use 0.5 mol / The potassium hydroxide solution of L was neutralized to PH=7 at room temperature, left standstill to remove the lower layer liquid, retained the upper layer epoxy cardanol, then repeatedly stirred with 2000 parts by mass of water to stand still to remove the lower layer liquid, repeated three times, the epoxy cardanol was in Vacuum dehydration at 100℃ to moisture ≤500ppm, the quality of hydrogen peroxide can be selected from 550 parts, 560 parts, 580 parts, 600 parts, 620 parts, 650 parts, and the quality of formic acid can be selected from 40 parts, 42 parts, 44 parts, 46 parts, 48 parts Parts, 52 parts, phosphoric acid can choose 10 parts, 12 parts, 16 parts, 18 parts, 20 parts, 22 parts.

[0036] Step 2: 300-330 parts by mass of ...

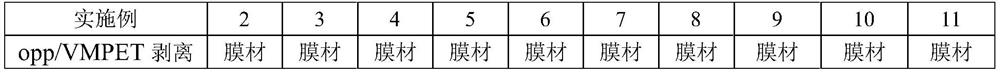

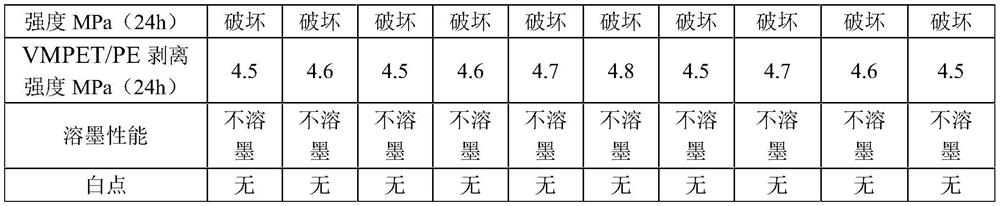

Embodiment 2

[0039] 2000 parts by mass of cardanol, 550 parts by mass of hydrogen peroxide, 40 parts by mass of formic acid, and 10 parts by mass of phosphoric acid were heated to a temperature of 60° C., reacted for 6 h, and then neutralized with 0.5 mol / L potassium hydroxide solution at room temperature To PH=7, stand to remove the lower layer liquid, retain the upper layer epoxy cardanol, then use 2000 mass parts of water to repeatedly stir and stand to remove the lower layer liquid, repeat three times, the epoxy cardanol is vacuum-dehydrated at 100 ° C to moisture≤500ppm, Epoxidized cardanol is obtained. 300 parts by mass of epoxy cardanol intermediate product, 150 parts by mass of phthalic anhydride, 110 parts by mass of diethylene glycol, and 30 ppm of catalyst were reacted at 230°C to prepare cardanol polyester polyol. 500 parts by mass of the cardanol polyester polyol product, 50 ppm of catalyst, and 550 parts by mass of propylene oxide at 60°C were introduced, and after the passag...

Embodiment 3

[0042] 2000 parts by mass of cardanol, 560 parts by mass of hydrogen peroxide, 42 parts by mass of formic acid, and 12 parts by mass of phosphoric acid were heated to a temperature of 60 ° C, reacted for 6 h, and then neutralized at room temperature with 0.5 mol / L potassium hydroxide solution To PH=7, stand to remove the lower layer liquid, retain the upper layer epoxy cardanol, then use 2000 mass parts of water to repeatedly stir and stand to remove the lower layer liquid, repeat three times, the epoxy cardanol is vacuum-dehydrated at 100 ° C to moisture≤500ppm, Epoxidized cardanol is obtained. 305 parts by mass of epoxy cardanol intermediate product, 148 parts by mass of phthalic anhydride, 108 parts by mass of diethylene glycol, and 40 ppm of catalyst were reacted at 230° C. to prepare cardanol polyester polyol. 510 parts by mass of the cardanol polyester polyol product, 60 ppm of catalyst, and 540 parts by mass of propylene oxide at 60° C. were passed through, and after pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com