Transfer method of transition metal chalcogenide two-dimensional material

A transition metal chalcogenide, two-dimensional material technology, used in molybdenum sulfide, climate sustainability, final product manufacturing, etc. The effect of improving form and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

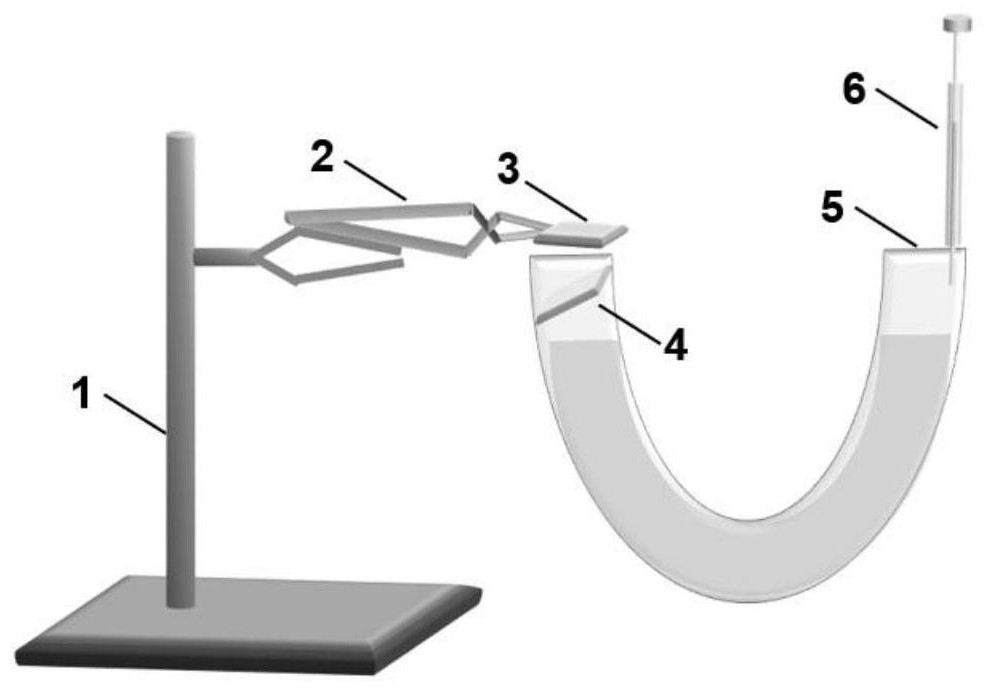

[0086] The following implementation cases are listed figure 1 device, but it does not constitute a necessary limitation of the technical solution of the present invention.

[0087] like figure 1 As shown, the present invention provides a device for utilizing water to transfer two-dimensional MoS2, comprising:

[0088] The device for two-dimensional MoS2 prepared by the water transfer CVD method proposed in the present disclosure mainly includes an iron stand (1), self-locking tweezers (2), a target substrate (3), a growth substrate (4), a U-shaped glass tube (5) and Microsampler (6).

[0089] specifically:

[0090] The water iron stand is used to fix the self-locking tweezers, and the tail of the self-locking tweezers can be glued to the iron stand fixture with double-sided tape. Self-locking forceps are used to hold the target substrate with the surface to be transferred facing down. The surface of the growth substrate is 2D MoS prepared by CVD 2 . The U-shaped tube is...

Embodiment 1

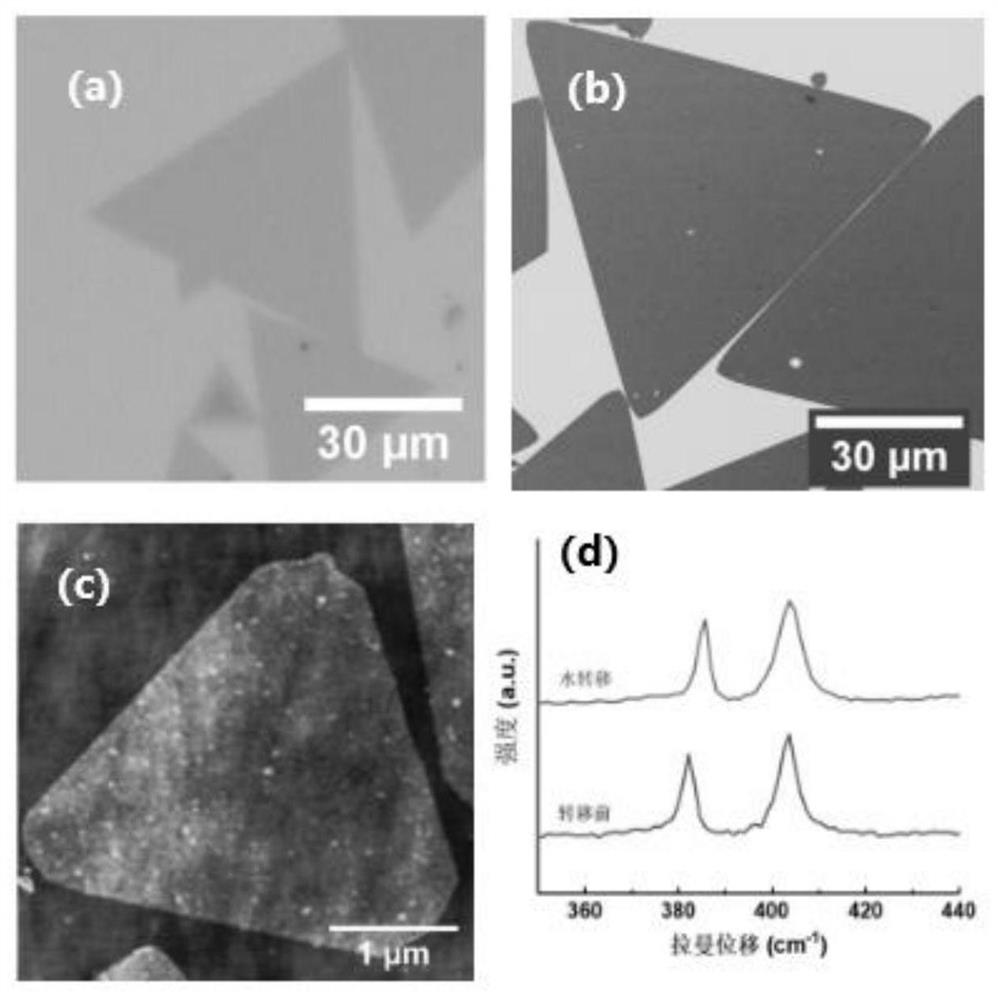

[0091] Example 1: Two-dimensional MoS 2 transfer

[0092] Step 1: Preparation of 2D MoS by Na-salt-assisted CVD 2 preparation:

[0093] Step (1-a): Substrate Pretreatment

[0094] Using a plasma cleaner, the surface of the substrate was treated with oxygen at a power of 60w for 50 seconds, and the silicon wafer (the surface was a layer of 280nm thick amorphous SiO 2 , the following is monocrystalline silicon) surface treatment as a hydrophilic surface. Subsequently, 30 mL of 0.1 mol / L NaCl solution was added dropwise to the surface of the silicon wafer, and then spin-coating was performed at a rotational speed of 4000 rpm. A substrate compounded with sodium chloride is prepared;

[0095] Step (1-b): Two-dimensional MoS 2 Preparative deposition

[0096] The reaction device is a dual-temperature zone tube furnace. Argon gas needs to be introduced into the device as a carrier gas. Along the direction of the carrier gas, the upstream temperature zone furnace is set to heat...

Embodiment 2

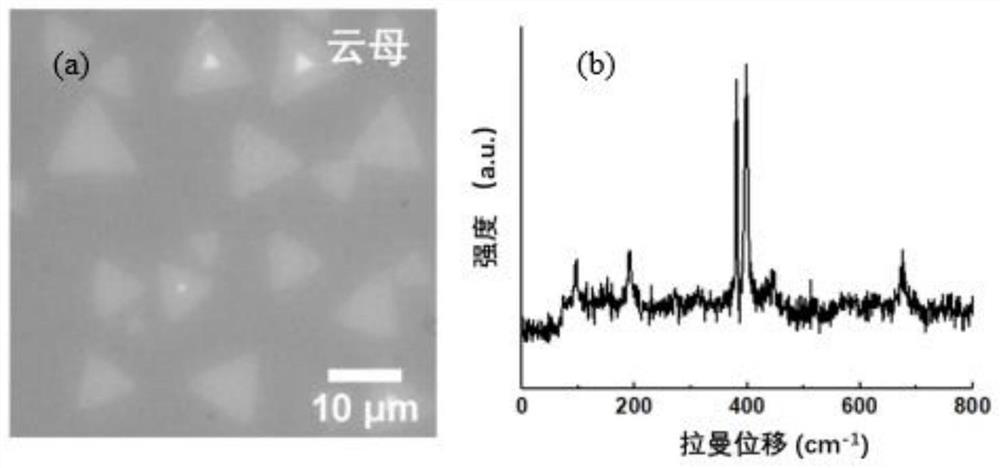

[0103] Compared with Example 1, the only difference is that the target substrate is changed to mica, and other operations and parameters are the same as Example 1.

[0104] image 3 a is the use of water transfer method to transfer the monolayer MoS 2 Optical microscope pictures transferred to mica. image 3 b is the use of water transfer method to transfer the monolayer MoS 2 The Raman spectrum transferred to mica indicates that the transferred sample has high quality and high crystallinity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com