Brown zirconia ceramic material and preparation method thereof

A zirconia ceramic and zirconia technology are applied in the field of brown zirconia ceramic materials and their preparation, which can solve the problems of improving the fracture toughness and flexural strength of zirconia ceramics and reducing the sintering temperature, and achieve stable coloring effect and high density. High, chemically stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

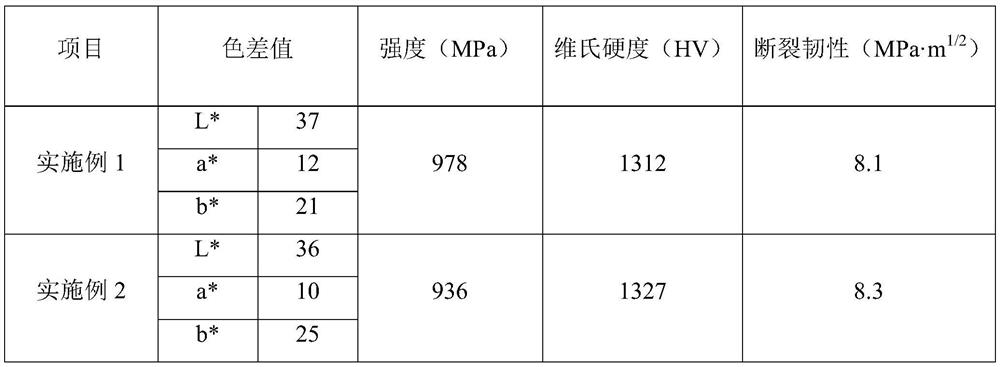

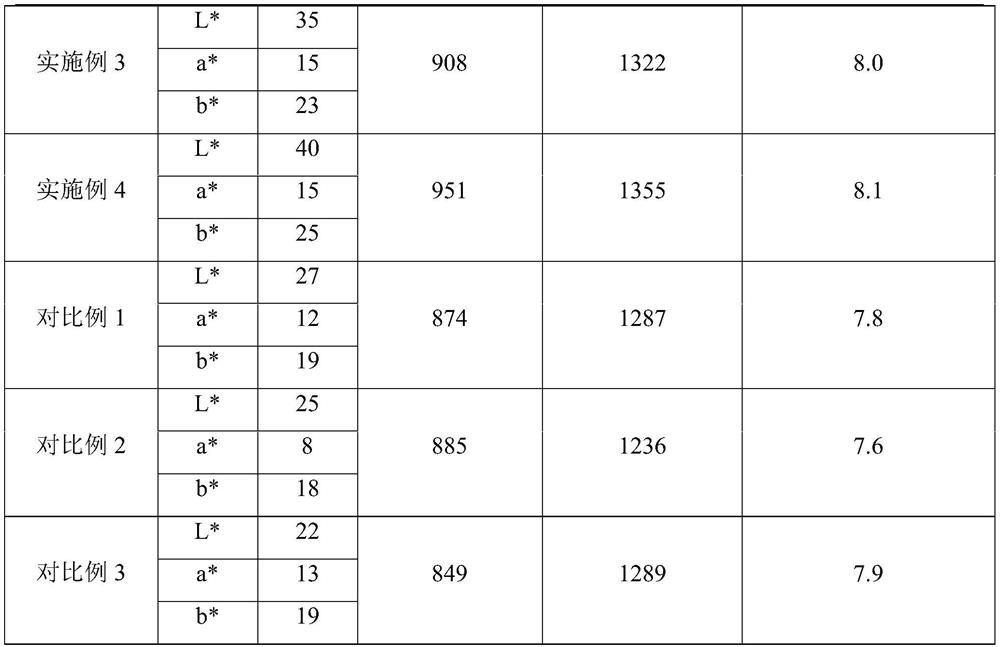

Examples

Embodiment 1

[0032] A preparation method of brown zirconia ceramic material, the method is as follows:

[0033] (1) by weight, take by weighing 43 parts of manganese dioxide, 15 parts of earth red, 28 parts of chromium oxides, 11 parts of iron oxides, 3 parts of zinc oxides, and mix uniformly to obtain colorant powder;

[0034] (2) adding the colorant powder into deionized water, preparing a slurry with a solid content of 75%, adding linoleic acid accounting for 0.6% of the total mass of the colorant powder, and uniformly ball-milling to obtain the colorant slurry;

[0035] (3) adding the zirconia powder into deionized water to prepare a slurry with a solid content of 70%, adding stearamide accounting for 0.08% of the mass of the zirconia powder, and uniformly ball-milling to obtain the zirconia slurry;

[0036] (4) according to the percentage of colorant powder 10wt% and zirconia powder 90wt%, slowly pour the colorant slurry into the zirconia slurry, and keep stirring to make it evenly mi...

Embodiment 2

[0040] A preparation method of brown zirconia ceramic material, the method is as follows:

[0041] (1) by weight, take by weighing 44 parts of manganese dioxide, 15 parts of earth red, 26 parts of chromium oxides, 13 parts of iron oxides, 2 parts of zinc oxides, and mix uniformly to obtain colorant powder;

[0042] (2) adding the colorant powder into deionized water to prepare a slurry with a solid content of 65%, adding lanolin that accounts for 0.5% of the colorant powder mass, and uniformly ball-milling to obtain the colorant slurry;

[0043] (3) adding the zirconia powder into deionized water to prepare a slurry with a solid content of 75%, adding stearamide accounting for 0.05% of the mass of the zirconia powder, and uniformly ball-milling to obtain the zirconia slurry;

[0044](4) according to the percentage of colorant powder 9wt% and zirconia powder 91wt%, slowly pour the colorant slurry into the zirconia slurry, and keep stirring to make it evenly mixed to obtain a mi...

Embodiment 3

[0048] A preparation method of brown zirconia ceramic material, the method is as follows:

[0049] (1) by weight, take by weighing 45 parts of manganese dioxide, 16 parts of earth red, 25 parts of chromium oxides, 10 parts of iron oxides, 4 parts of zinc oxides, and mix uniformly to obtain colorant powder;

[0050] (2) adding the colorant powder into deionized water to prepare a slurry with a solid content of 70%, adding lanolin that accounts for 0.7% of the colorant powder mass, and uniformly ball-milling to obtain the colorant slurry;

[0051] (3) adding the zirconia powder into deionized water to prepare a slurry with a solid content of 70%, adding fatty acid accounting for 0.05% of the mass of the zirconia powder, and uniformly ball-milling to obtain the zirconia slurry;

[0052] (4) according to the percentage of colorant powder 8wt% and zirconia powder 92wt%, slowly pour the colorant slurry into the zirconia slurry, and keep stirring to make it evenly mixed to obtain a m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com