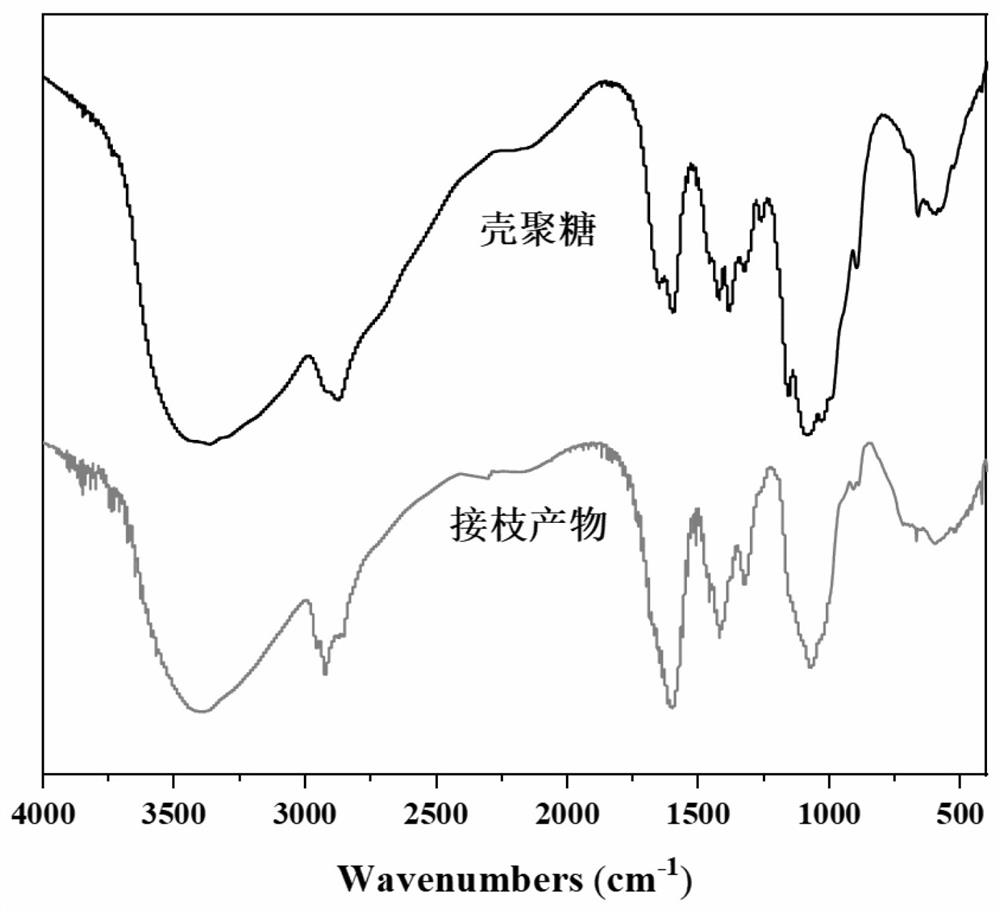

Modified carboxymethyl chitosan quaternary ammonium salt and preparation method thereof

A technology of carboxymethyl chitosan and quaternary ammonium salt, which is applied in the field of modified carboxymethyl chitosan quaternary ammonium salt and its preparation, can solve the problem of inaccurate grafting position, variable molecular weight, and variable grafting efficiency To achieve the effect of easy degradation, simple reaction conditions, and increase of adsorption sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

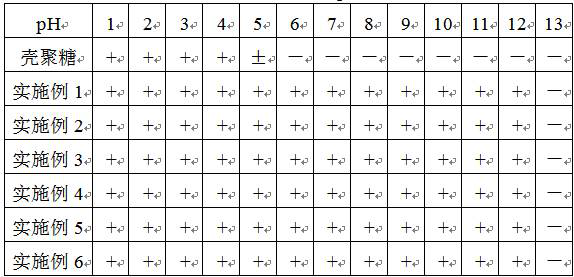

Examples

preparation example Construction

[0039] The preparation method of O-carboxymethyl chitosan quaternary ammonium salt is:

[0040]Add 18~21mL of kerosene to the three-necked flask, add 1.4~1.6g of a mixture of span-60 and tween-80 (HLB value 6~7) under stirring, stir for 5~15min, and stir at a rate of 200~400r / min. Add 10~12mL water and 1.0g O-carboxymethyl chitosan to the beaker and stir for 5~15min, then add the solution to the three-necked flask and stir at room temperature for 30~60min at a stirring rate of 200~400r / min. Add 0.006~0.008g of ceric ammonium nitrate, adjust the temperature to 50~70°C, carry out the initiation reaction for 20~30min, and the stirring speed is 200~400r / min. After initiating the reaction, add 8~10mL of an aqueous solution containing 2~4g of trihydroxyethyl allyl quaternary ammonium salt into the three-necked flask, and react at a temperature of 50~70°C for 4~5h, with a stirring rate of 200~400r / min. After the reaction is completed, a mixed solution of 40 to 80 parts by volume is ...

Embodiment 1

[0042] Add 20 mL of kerosene to the three-necked flask, add 1.5 g of a mixture of span-60 and tween-80 under stirring (span-60 to tween-80 ratio is 4:1), stir for 15 min, and stir at a rate of 400 r / min. Add 12 mL of water and 1.0 g of O-carboxymethyl chitosan to the beaker and stir for 10 min, then add the solution to the three-necked flask and stir at room temperature for 40 min at a stirring rate of 400 r / min. 0.006g of cerium ammonium nitrate was added, the temperature was adjusted to 70°C, and the reaction was initiated for 30min, with a stirring speed of 400r / min. After initiating the reaction, 8 mL of an aqueous solution containing 3 g of trihydroxyethyl allyl quaternary ammonium salt was added to the three-necked flask, and the reaction was carried out at a temperature of 70° C. for 4 h with a stirring rate of 400 r / min. After the reaction, 60 ml of a mixed solution with a volume ratio of ethanol and acetone of 1:2 was added, and the mixture was rapidly stirred for dem...

Embodiment 2

[0044] Add 20 mL of kerosene to the three-necked flask, add 1.4 g of a mixture of span-60 and tween-80 under stirring (the ratio of span-60 to tween-80 is 4:1), and stir for 12 min at a stirring rate of 400 r / min. Add 10 mL of water and 1.2 g of O-carboxymethyl chitosan to the beaker and stir for 10 min, then add the solution to the three-necked flask and stir at room temperature for 40 min at a stirring rate of 400 r / min. 0.008 g of cerium ammonium nitrate was added, the temperature was adjusted to 70° C., and the initiation reaction was carried out for 40 min with a stirring rate of 400 r / min. After the reaction was initiated, 10 mL of an aqueous solution containing 4 g of trihydroxyethyl allyl quaternary ammonium salt was added to the three-necked flask, and the reaction was carried out at a temperature of 70° C. for 4 h with a stirring rate of 400 r / min. After the reaction, 60 ml of a mixed solution with a volume ratio of ethanol and acetone of 1:2 was added, and the mixtu...

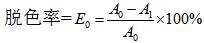

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com