Atomic layer deposition method of cobalt-based oxide film

A technology of oxide thin film and atomic layer deposition, applied in coating, gaseous chemical plating, metal material coating process, etc., to achieve the effect of precise and controllable film thickness, good step coverage and low deposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 A kind of atomic layer deposition method of cobalt-based oxide thin film

[0037] (1) Cobalt metal precursor: dicarbonyltrimethylsilylcyclopentadienyl cobalt (TMSCpCo(CO) 2 ,C 10 H 13 CoSiO 2 ), wherein Cp is cyclopentadiene, TMS is trimethylsilyl, and C≡O: carbonyl.

[0038] The chemical structural formula of the cobalt metal precursor is shown below:

[0039]

[0040] (2) co-reactant: ozone;

[0041] (3) Substrate: Si [can also be SiO 2 , glass (glass), sapphire (sapphire), etc.];

[0042] (4) Carrier gas and cleaning gas: high-purity nitrogen;

[0043] (5) Substrate cleaning: first ultrasonically clean with acetone for ten minutes, then ultrasonically clean with absolute ethanol for ten minutes, then ultrasonically clean with deionized water for ten minutes, and finally blow dry with high-purity nitrogen for use

[0044] (6) Open the ALD chamber, place the cleaned substrate in the reaction chamber, and evacuate the chamber to 0hPa; finally, ad...

Embodiment 2

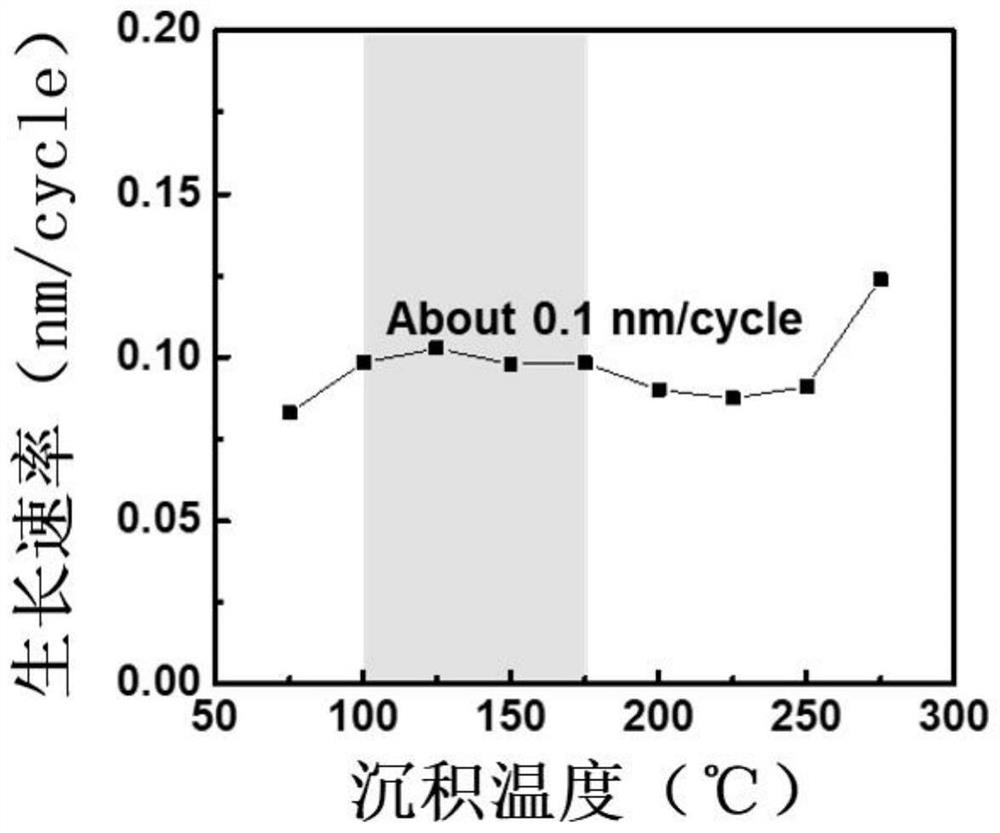

[0051] Example 2 Exploration test of heating temperature and co-reactant species of metal precursor for successful cobalt-based oxide thin film growth

[0052] Experiment 1: Different metal precursors (TMSCpCo(CO) 2 ,C 10 H 13 CoSiO 2 ) Effect of heating temperature on the ALD deposition process of cobalt oxide thin films

[0053] Dicarbonyltrimethylsilylcyclopentadienyl cobalt (TMSCpCo(CO) 2 ,C 10 H 13 CoSiO 2 ) as the metal precursor, ozone as the co-reactant, and Si [can also be SiO 2 , glass (glass), sapphire (sapphire), etc.] as the substrate, with high-purity nitrogen as the carrier gas and cleaning gas. First, the substrate was cleaned by ultrasonic cleaning with acetone for 10 minutes, absolute ethanol for 10 minutes, then ultrasonic cleaning with deionized water for 10 minutes, and finally dried with high-purity nitrogen for use. Then open the ALD chamber, place the cleaned substrate in the reaction chamber, and evacuate the chamber to 0 hPa; finally, adjust ...

Embodiment 3

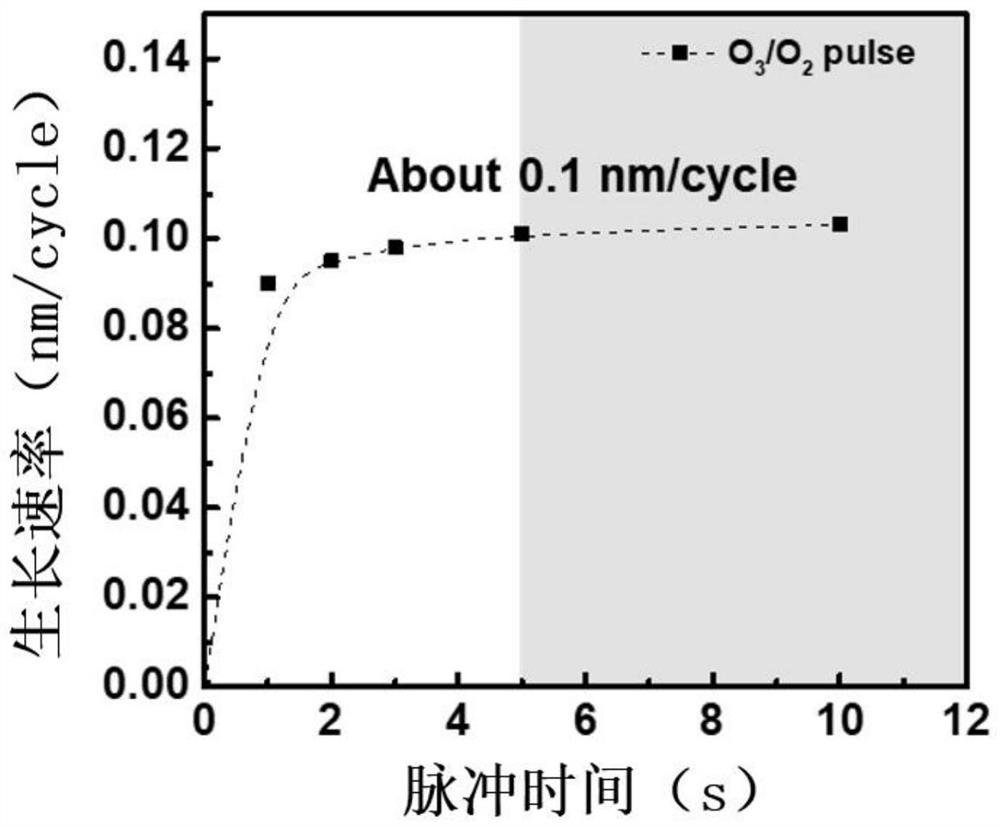

[0063] Example 3 Exploration test of ALD deposition parameters that can successfully realize the growth of cobalt-based oxide thin films

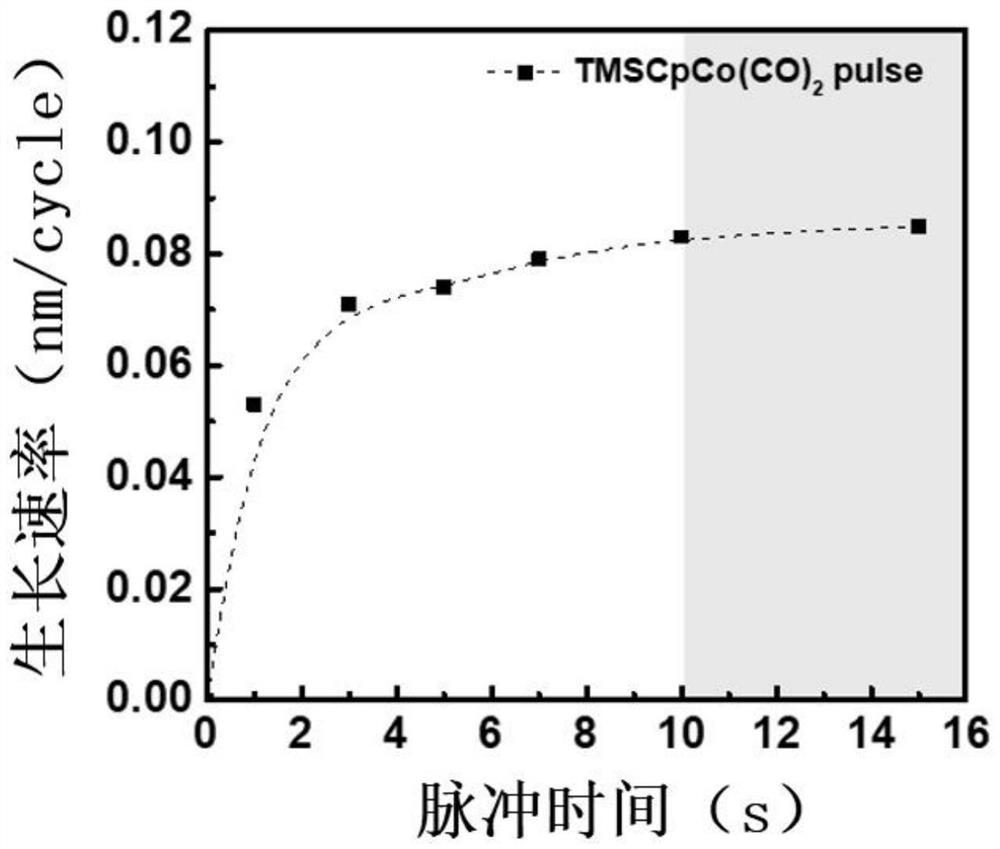

[0064] Experiment 1: Effect of Pulse Time of Metal Precursor on Cobalt Oxide Thin Film ALD Deposition Process

[0065] The bulk method is the same as that of Test 1 in Example 1, except that the pulse times of the precursors are 1s, 3s, 5s, 7s, 10s, and 15s, respectively.

[0066] Depend on figure 1 It can be seen that at the deposition temperature of 150 °C, the carrier gas flow rate is 100 sccm, the ozone pulse time is 0.5 s, and the purging time is 10 s, when the metal precursor pulse time reaches 10 s, the saturation growth of the cobalt oxide film can be achieved. The growth rate remains stable at about 0.083 nm / cycle (the time when the growth rate reaches saturation can be used as a suitable time for the metal precursor pulse). DescriptionTMSCpCo(CO) 2 The stable deposition of the film can be achieved when the pulse time is 10s, an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap