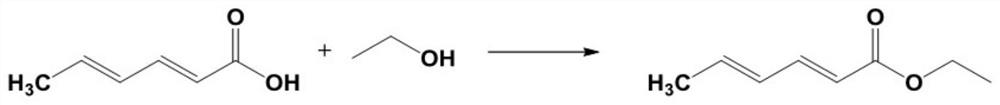

Method for preparing ethyl sorbate through catalysis of supported p-toluenesulfonic acid

A technology of p-toluenesulfonic acid and ethyl sorbate, which is applied in the directions of carboxylate preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of long reaction time, many side reactions, poor product quality, etc. Achieve recovery and reuse, improved yield and purity, and minimal loss of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0046] Acidify 100 g of sodium montmorillonite with 1 L of 2 mol / L hydrochloric acid for 3 h, collect the solid by suction filtration and wash repeatedly until the pH of the filtrate is > 6, dry the filter cake under vacuum at 60°C and grind to obtain activated montmorillonite ; It was added to 500ml of 25wt% p-toluenesulfonic acid aqueous solution, stirred at 50°C for 4h, then incubated for 8h, filtered under reduced pressure, and the filter cake was repeatedly washed and then dried and ground under vacuum at 70°C. After cooling, 131 g of supported p-toluenesulfonic acid catalyst 1 was obtained. Calculated by weight method, the p-toluenesulfonic acid loading was 33 wt%.

preparation example 2

[0048]Acidify 100 g of Na-based montmorillonite with 1 L of 3 mol / L hydrochloric acid for 3 h, collect the solid by suction filtration and wash repeatedly until the pH of the filtrate > 6, dry the filter cake under vacuum at 60°C and grind to obtain activated montmorillonite It was added to 500ml of 35wt% p-toluenesulfonic acid aqueous solution, stirred at 50°C for 4h, then kept for 8h and aged for 8h, filtered under reduced pressure, and the filter cake was repeatedly washed and then dried and ground under vacuum at 70°C. After cooling, 135 g of loaded p-toluenesulfonic acid catalyst 2 was obtained. Calculated by weight method, the p-toluenesulfonic acid loading was 37 wt%.

preparation example 3

[0050] Add 1 kg (14.3 mol) of crotonaldehyde, 93 g (0.7 mol) of aluminum trichloride, and 166 g (0.7 mol) of copper isobutyrate into the reaction kettle, and continuously bubble ketene under stirring (from acetic acid at 740-780 Cracked at a high temperature), the temperature of ketene does not exceed 25°C, the temperature of the reaction solution is controlled at 35-40°C, and the reaction is stirred for 3 hours to obtain polyester. After the reaction, the unreacted crotonaldehyde was recovered by distillation under reduced pressure; 2L of concentrated hydrochloric acid was added at a temperature lower than 40°C, the temperature was raised to 70°C, stirred for 1h, and then the temperature was further raised to 95°C, and stirred for 2h. After the reaction liquid is lowered to room temperature, filter, wash with water several times, and dry to obtain crude sorbic acid; place it in 70% ethanol, heat up to 65°C and stir to dissolve completely, add activated carbon for decolorizatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com