Vacuum brazing process for reducing corrosion of GH3536 honeycomb and GH4738 ring assembly

A brazing process and assembly technology, which is applied in the welding field of nickel-based superalloys, can solve problems such as hindering the development and application of vacuum brazing alloy components, reducing the strength of honeycomb structures, and severe corrosion of honeycomb feet, so as to achieve the reduction of base metal alloys. Dissolution, improve structural strength, reduce the effect of alloy corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

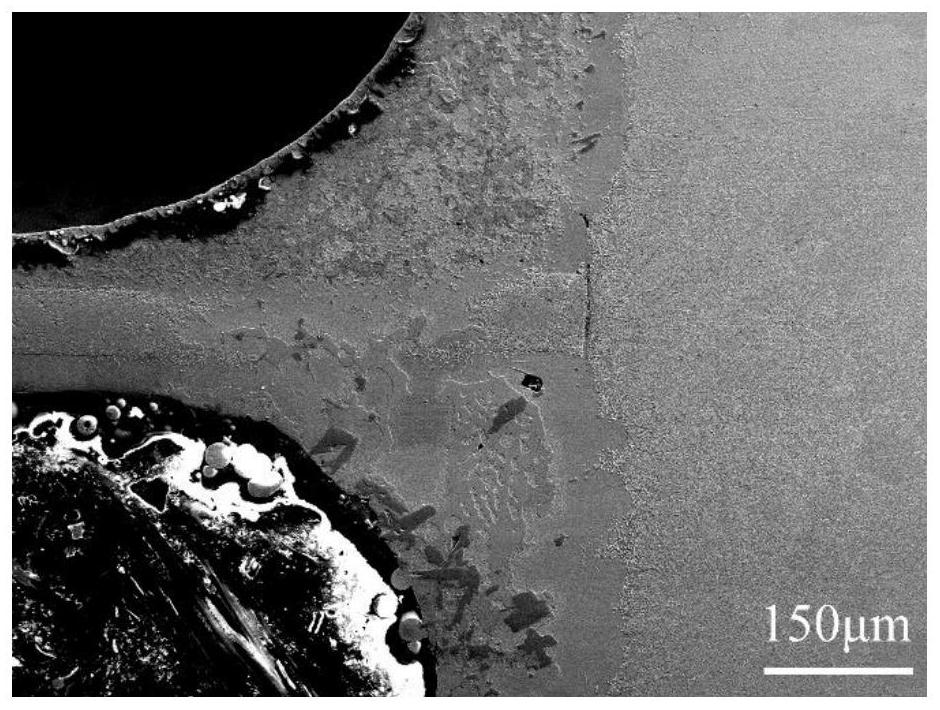

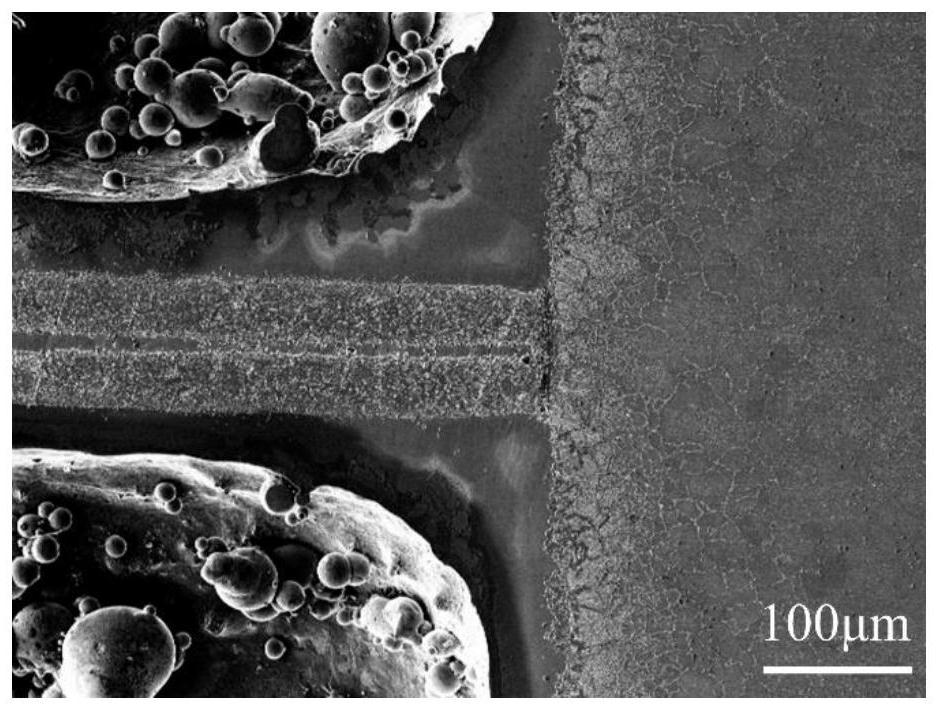

Image

Examples

Embodiment 1

[0031] Step 1: Use wire cutting to process the honeycomb into the required size; use 400#, 800# and 1200# sandpapers in turn to polish the surfaces to be welded of the honeycomb and the ring to remove the oxide scale on the surface of the base metal alloy and obtain a smooth surface; Acetone wipes the surface of the base metal to remove oil and other impurities;

[0032] Step 2: Use the gun electrode to position the honeycomb on the ring to complete the assembly and positioning;

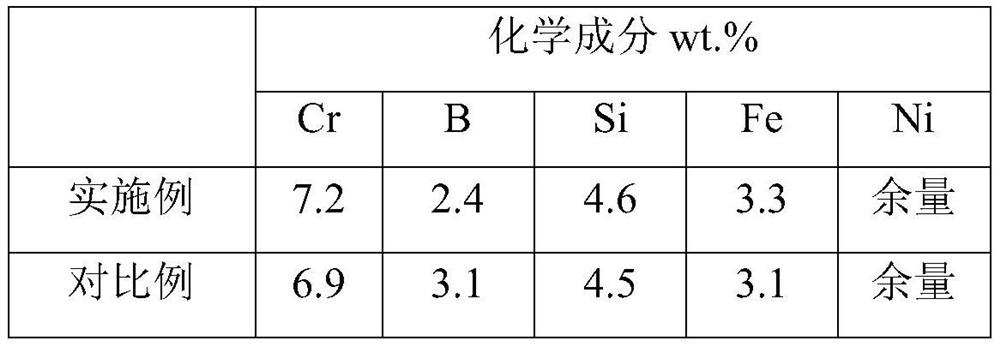

[0033] Step 3: Apply the prepared paste solder evenly between the honeycomb and the ring, and apply a flow blocking agent around the joint surface of the two to prevent the solder from flowing during the brazing process; the solder is nickel-based The brazing filler metal has a boron content of 2.4wt.% and a melting point of 991°C; the amount of brazing filler metal is controlled at about 2 times that required to fill the weld;

[0034] Step 4: Put the assembled assembly into the vacuum brazing furn...

Embodiment 2

[0041] Step 1: Use wire cutting to process the honeycomb into the required size; use 400#, 800# and 1200# sandpapers in turn to polish the surfaces to be welded of the honeycomb and the ring to remove the oxide scale on the surface of the base metal alloy and obtain a smooth surface; Acetone wipes the surface of the base metal to remove oil and other impurities;

[0042] Step 2: Use the gun electrode to position the honeycomb on the ring to complete the assembly and positioning;

[0043] Step 3: Evenly coat the prepared paste solder between the honeycomb and the ring, and apply a flow blocking agent around the joint surface of the two to prevent the solder from flowing during the brazing process; the solder is nickel-based The brazing filler metal has a boron content of 2.4wt.% and a melting point of 991°C; the filler filler content is controlled at about 2 times that required to fill the weld;

[0044] Step 4: Put the assembled assembly into the vacuum brazing furnace, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com