Method for preparing n-butyl thiourea

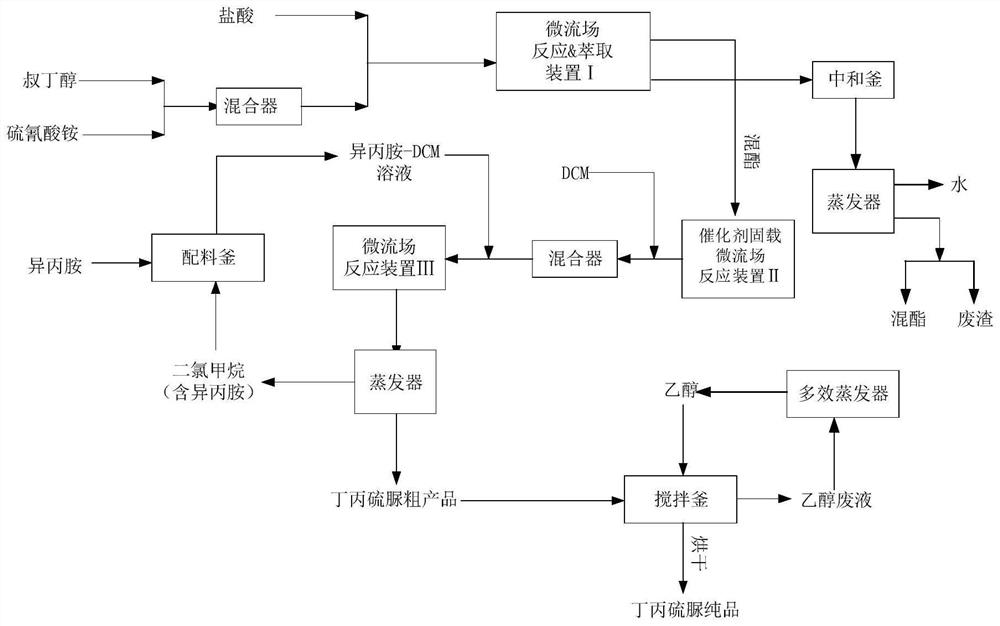

A technology of butylthiourea and isopropylamine, which is applied in the field of synthesis of butylthiourea, can solve problems such as complex operation steps, low heat and mass transfer efficiency, and long production time, and achieve improved reaction rate and heat and mass transfer efficiency , Improve the degree of automation control, simplify the effect of production operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

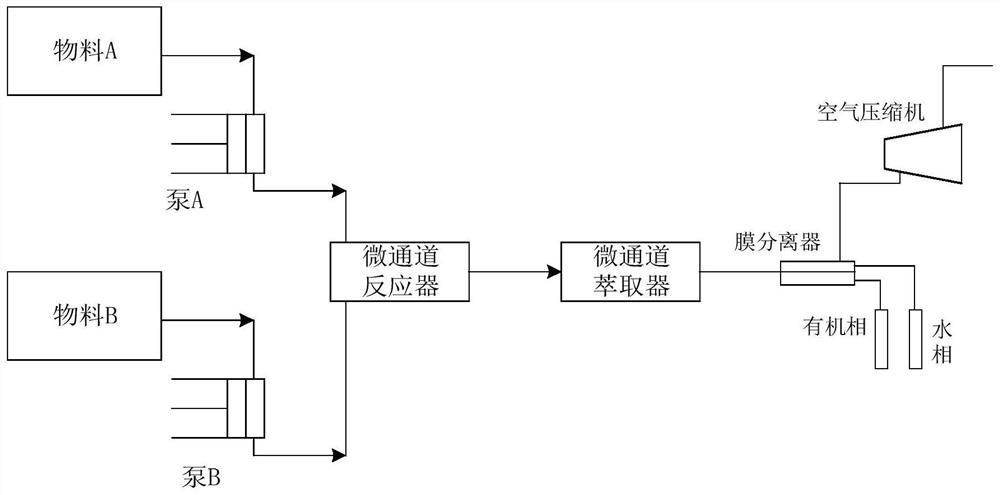

Method used

Image

Examples

Embodiment 1

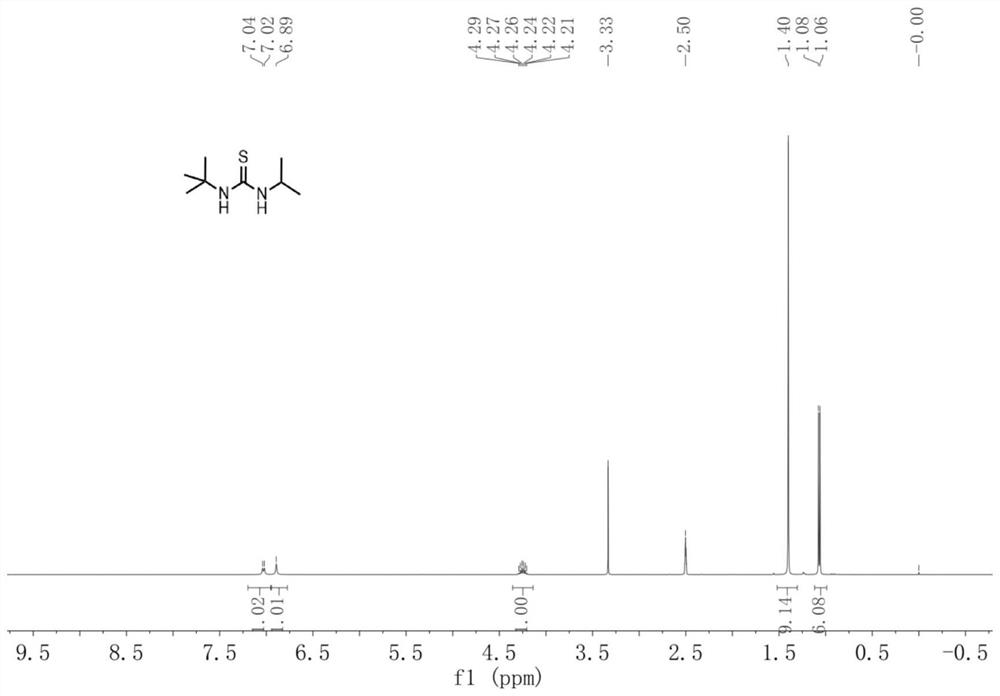

[0030] Dissolve 16.3 g (0.22 mol) of tert-butanol and 15.2 g (0.2 mol) of ammonium thiocyanate in 19 g of water to obtain a homogeneous solution, which is ready to use. Take the prepared solution and 20% hydrochloric acid solution through a high-pressure syringe pump and pump it into the microreactor. The flow rate ratio of tert-butanol-ammonium thiocyanate solution and hydrochloric acid is 3:2, and the reaction solution is reacted at 85 ° C, adjusting The outlet pressure of the reactor makes the reaction liquid flow stably in the reaction system. The reaction residence time is 10 minutes. The effluent liquid enters the microfluidic field extraction device. After staying for 3 minutes, the aqueous phase and the organic phase are separated by a membrane separator. Ester; the mixed ester was pumped into the microreactor immobilized with zinc chloride at 0.75mL / min, the reaction temperature was 65°C, and stayed for 5 minutes; the sample obtained was isoester, and the mass of the o...

Embodiment 2

[0032] Dissolve 14.8 g (0.2 mol) of tert-butanol and 15.2 g (0.22 mol) of ammonium thiocyanate in 19 g of water to obtain a homogeneous solution, ready to use. Take the prepared solution and 20% hydrochloric acid solution through a high-pressure syringe pump and pump it into the microreactor. The flow rate ratio of tert-butanol-ammonium thiocyanate solution and hydrochloric acid is 3:2, and the reaction solution is reacted at 85 ° C, adjusting The outlet pressure of the reactor makes the reaction liquid flow stably in the reaction system. The reaction residence time is 10 minutes. The effluent liquid enters the microfluidic field extraction device. After staying for 3 minutes, the aqueous phase and the organic phase are separated by a membrane separator. There is a small amount of solid adsorption in the membrane separator; the mixed ester is pumped into a microreactor with zinc chloride immobilized, the reaction temperature is 65 ° C, and the stay is 5 minutes; the sample obta...

Embodiment 3

[0034] Dissolve 16.3 g (0.22 mol) of tert-butanol and 15.2 g (0.2 mol) of ammonium thiocyanate in 19 g of water to obtain a homogeneous solution, which is ready to use. Take the prepared solution and 20% hydrochloric acid solution through a high-pressure syringe pump and pump into the microreactor. The flow rate ratio of tert-butanol-ammonium thiocyanate solution and hydrochloric acid is 3:2, and the reaction solution is reacted at 75 ° C. The residence time is 10 minutes, the effluent liquid enters the microfluidic field extraction device, and after staying for 3 minutes, the aqueous phase and the organic phase are separated by a membrane separator, and the organic phase is the mixed ester; Reactor, the reaction temperature is 65 ℃, stay for 5 minutes; the sample obtained is isoester, the obtained isoester mass is 21.6g, and the yield is 93.75%; 21.6g (0.188mol) isoester is passed through 40g dichloride Methane was dissolved, 12g (0.2mol) of isopropylamine was dissolved using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com