Conductive paste, preparation method and application thereof

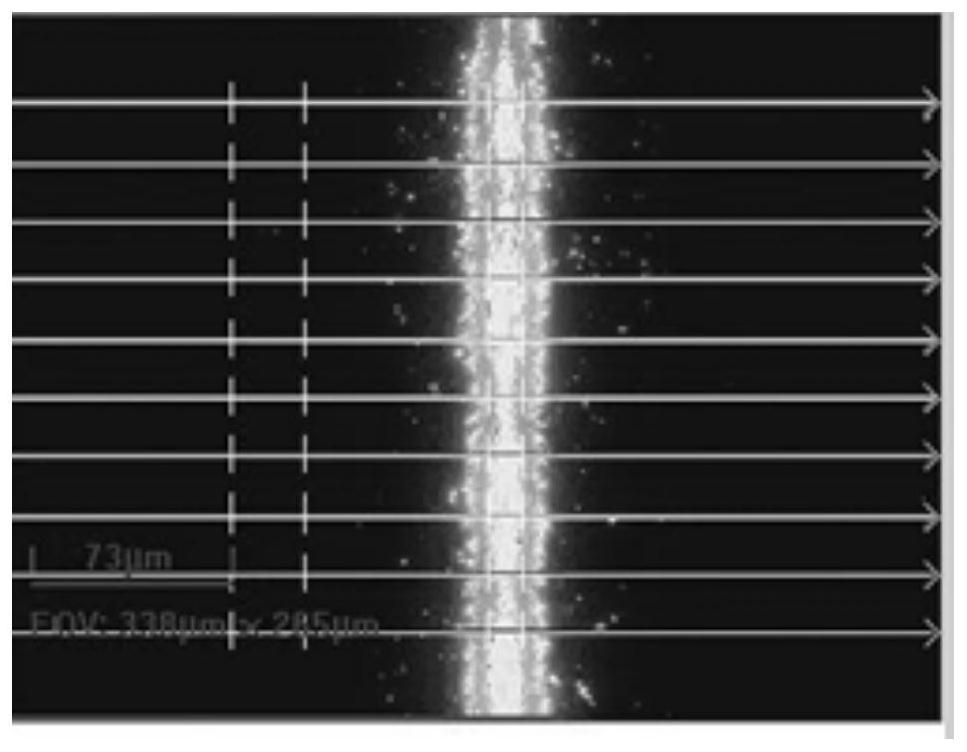

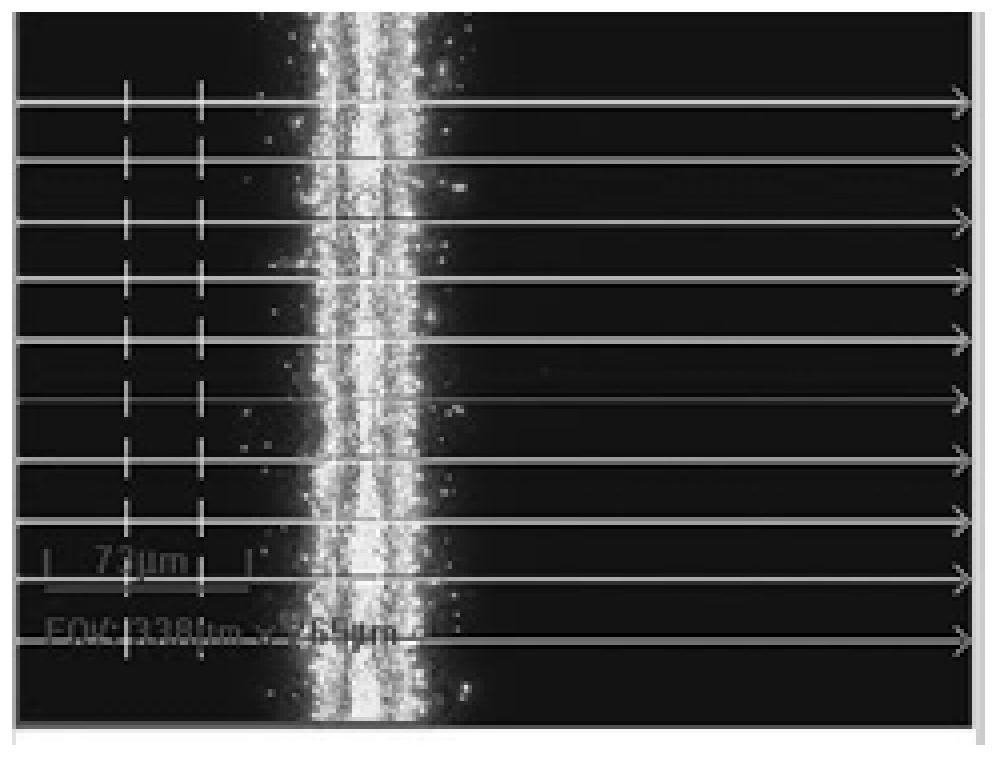

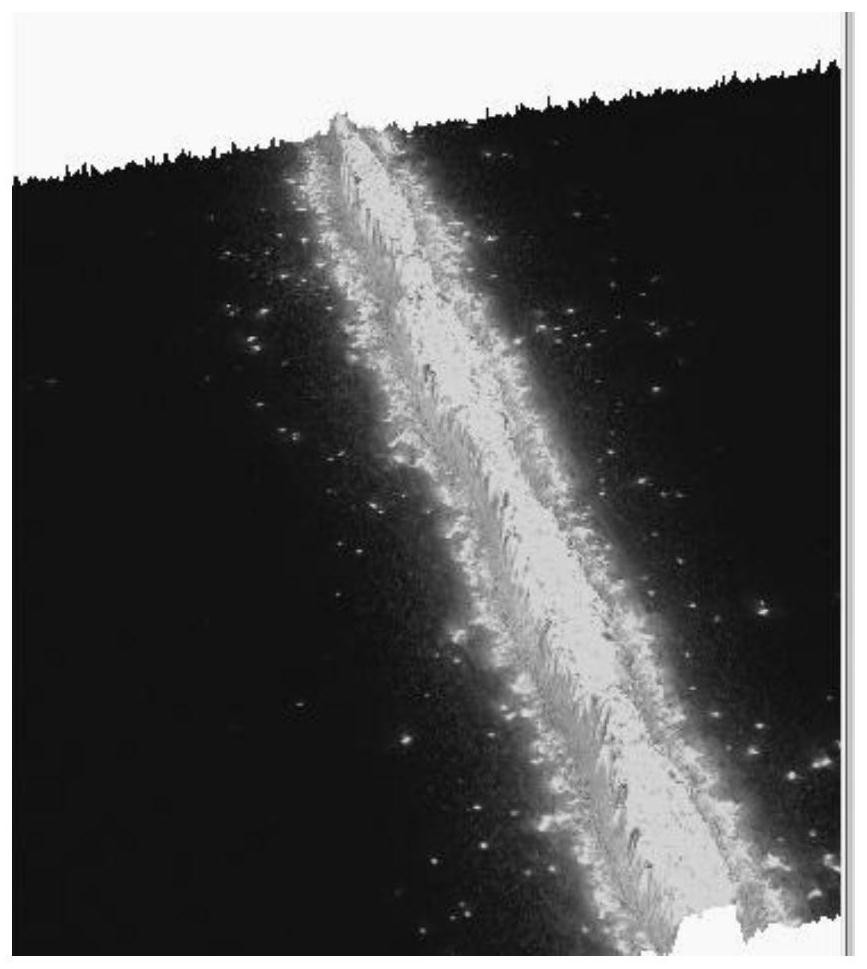

A technology of conductive paste and raw materials, applied in conductive materials dispersed in non-conductive inorganic materials, cable/conductor manufacturing, circuits, etc., can solve the problem of uneven line width, low material utilization, complex process, etc. problems, to achieve the effect of improving photoelectric conversion efficiency, improving screen printing quality, and narrowing the line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] According to the parts by mass, fully mix 0.1 part of polyurethane resin, 0.3 part of modified hydrogenated castor oil, 0.3 part of alkylammonium salt type cationic surfactant and 7.3 parts of butyl carbitol to obtain an organic carrier; 90 parts of silver powder Pre-mix with 2 parts of glass powder evenly, and then add the organic carrier to the mixture of silver powder and glass powder according to the principle of equal increment. After each addition, stir evenly, and add the next time. After all additions are completed, stir at high speed. Finally, the mixture is ground by a three-roller machine with a particle size of less than 6 μm, and filtered to obtain conductive silver paste.

Embodiment 2

[0043] According to the parts by mass, 1.0 parts of polyurethane resin, 0.3 parts of polyamide wax, 0.3 parts of BYK180 and 6.4 parts of alcohol ester-12 are fully mixed to obtain an organic carrier; 90 parts of silver powder and 2 parts of glass powder are pre-mixed uniformly, and then the organic The carrier is added to the mixture of silver powder and glass powder according to the principle of equal increment. After each addition, stir evenly, and add the next time. After all additions, stir at high speed. Finally, the mixture is ground by a three-roller machine with a particle size of less than 6 μm, and filtered to obtain conductive silver paste.

Embodiment 3

[0045] According to the mass parts, fully mix 0.4 parts of polyurethane resin, 0.3 parts of polyamide wax, 0.3 parts of Digao 655 and 7.0 parts of diethyl phthalate to obtain an organic carrier; 92 parts of silver powder and 2 parts of glass powder are pre-mixed Mix well, and then add the organic vehicle to the mixture of silver powder and glass powder according to the principle of equal increment. After each addition, stir evenly, and add the next time. After all additions, stir at high speed. Finally, the mixture is ground by a three-roller machine with a particle size of less than 6 μm, and filtered to obtain conductive silver paste.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com