Pleuromutilin derivative containing 1, 2, 4-triazole acrylamide side chain as well as preparation method and application of pleuromutilin derivative

A technology of triazole acrylamide and pleuromutilin, which is applied in the field of pleuromutilin derivatives and its preparation, can solve the problem of low drug resistance, and achieve the effects of high safety, convenient operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] (1) Preparation of Intermediate I

[0072]

[0073] Pleuromutilin (757.0 mg, 2 mmol) and p-toluenesulfonyl chloride (418.0 mg, 2.2 mmol) were dissolved in dichloromethane (30 mL), placed in a reactor, TEA (0.8 mL, 6 mmol) and DMAP (24.4 mg, 0.2 mmol), stirred at room temperature for 5 h. The reaction solution was concentrated under reduced pressure, and the concentrated product was washed with saturated aqueous sodium bicarbonate solution (50 mL) to obtain Intermediate I (1012.1 mg, 1.9 mmol) in a yield of 95.0%. The prepared intermediate I was used as the starting material for intermediate II.

[0074] (2) Preparation of Intermediate II

[0075]

[0076] To a solution of 3-mercapto-1,2,4-triazole (242.7 mg, 2.4 mmol) in dichloromethane (10 mL) was added 1,8-diazabicycloundec-7-ene dropwise (DBU) (1.3 mL, 9 mmol), and the mixture was stirred at room temperature for 30 min, and then a solution of intermediate I (1065.4 mg, 2.0 mmol) in dichloromethane (10 mL) wa...

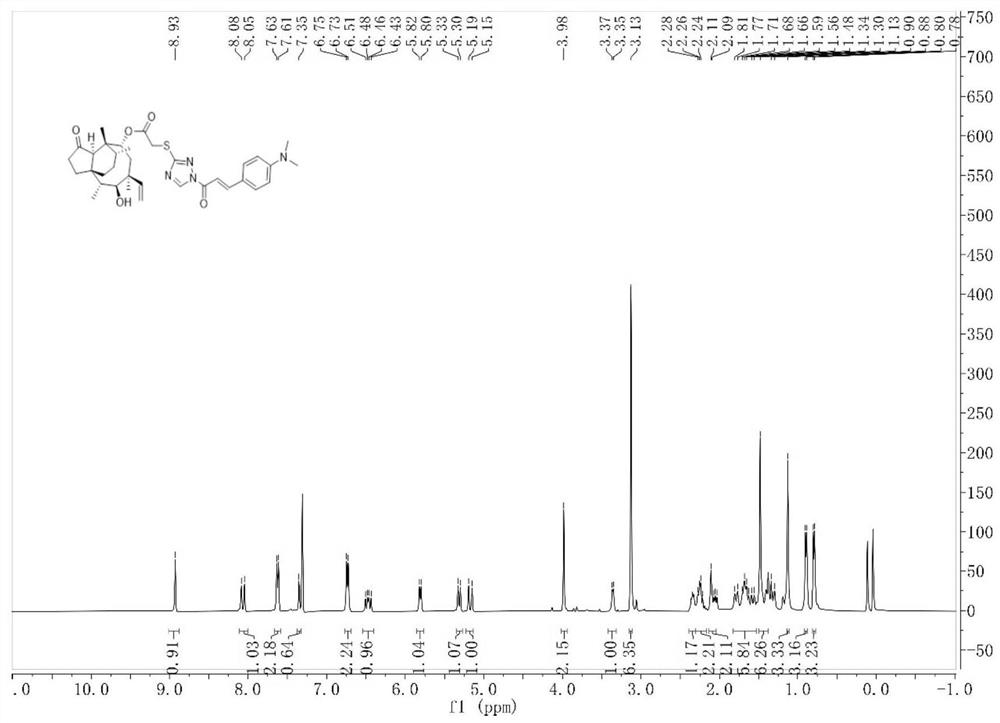

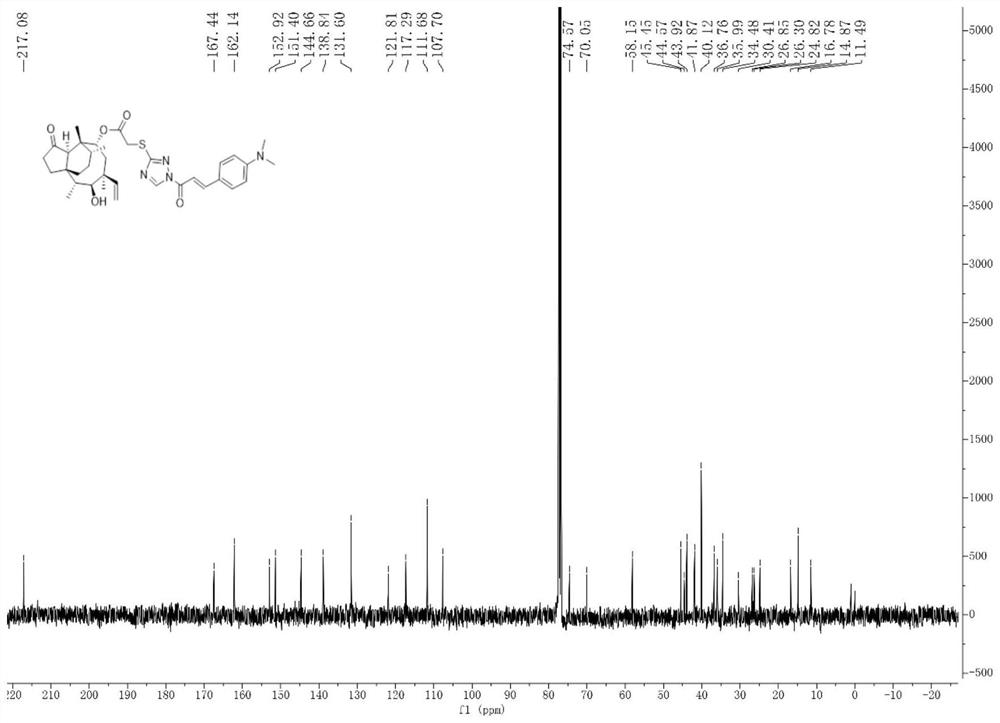

Embodiment 2

[0084] Compound 2: (3aR, 4R, 5R, 7S, 8S, 9R, 9aS, 12R)-8-hydroxy-4,7,9,12-tetramethyl-3-oxo-7-vinyldecahydro-4 ,9a-propylcyclopent[8]cycloalken-5-yl 2-((1-((E)-3-(4-(trifluoromethyl)phenyl)acryloyl)-1H-1,2 Preparation of ,4-triazol-3-yl)thio)acetate

[0085]

[0086] The preparation process of intermediate I and intermediate II was the same as that of Example 1. 4-Trifluorocinnamic acid (23.9 mg, 0.17 mmol) was dissolved in dichloromethane (10 mL), placed in a reactor, and DCC was added to the reaction solution. (41.2 mg, 0.2 mmol) and NMM (0.019 mL, 0.17 mmol), activated for 30 min, added Intermediate II (64.6 mg, 0.14 mmol), reacted at room temperature for 7 h, concentrated the reaction solution under reduced pressure, and the residue was subjected to column chromatography (200 -300-mesh silica gel powder was used as the stationary phase, and the mobile phase was petroleum ether:ethyl acetate (V:V)=1:1), and dried to obtain the final product compound 2 (51.632 mg, 0.112 ...

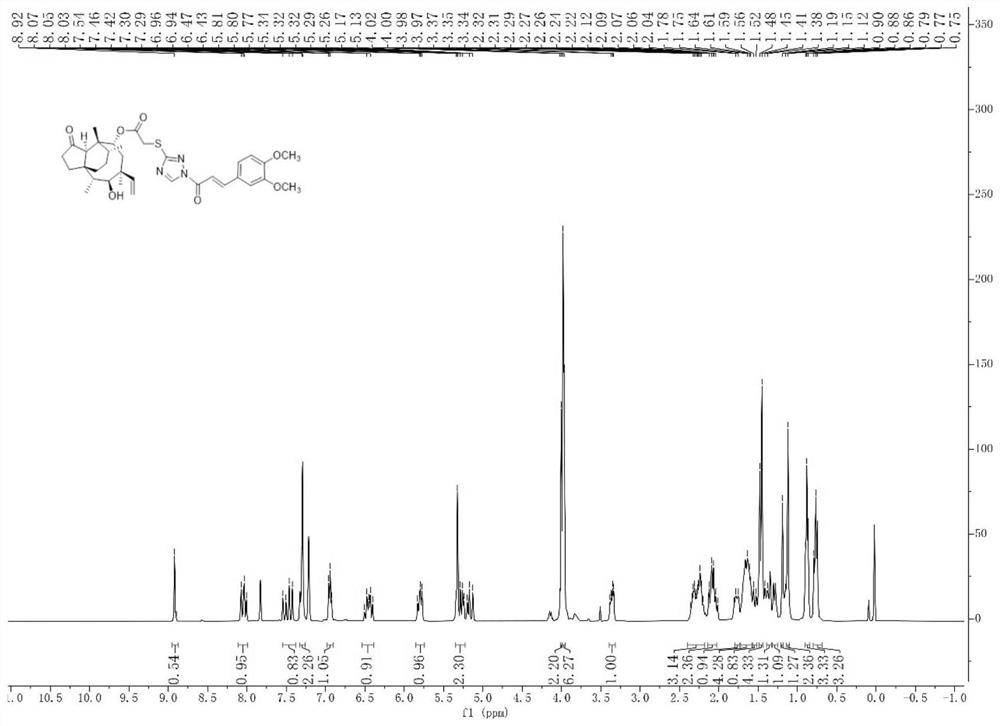

Embodiment 3

[0090] Compound 3: (3aR, 4R, 5R, 7S, 8S, 9R, 9aS, 12R)-8-hydroxy-4,7,9,12-tetramethyl-3-oxo-7-vinyldecahydro-4 ,9a-Propcyclopenta[8]cycloalken-5-yl 2-((1-((E)-3-(thiophen-3-yl)acryloyl)-1H-1,2,4-triazole- Preparation of 3-yl)thio)acetate

[0091]

[0092] The preparation process of intermediate I and intermediate II was the same as that of Example 1. Trans-3-(3-thienyl)acrylic acid (24.7 mg, 0.16 mmol) was dissolved in acetonitrile (5 mL), placed in a reactor, and added to the reaction solution. Add EDCI (38.4 mg, 0.2 mmol), HOBT (27 mg, 0.2 mmol) and TEA (0.023 mL, 0.17 mmol), activate for 30 min, add intermediate II (64.6 mg, 0.14 mmol), react at room temperature for 9 h, and concentrate under reduced pressure The reaction solution and the residue were separated and purified by column chromatography (200-300 mesh silica gel powder was the stationary phase, and the mobile phase was dichloromethane:methanol (V:V)=30:1), and dried to obtain the final product compound 3 (50....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com