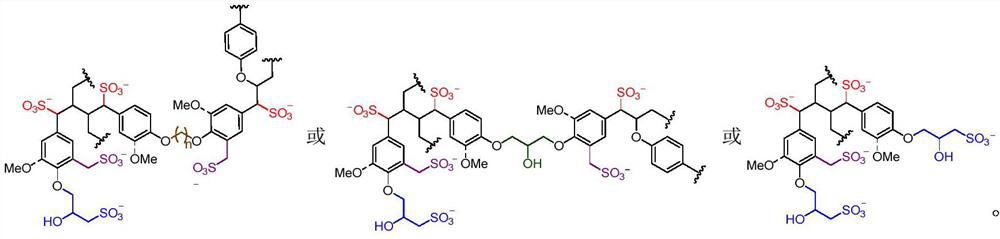

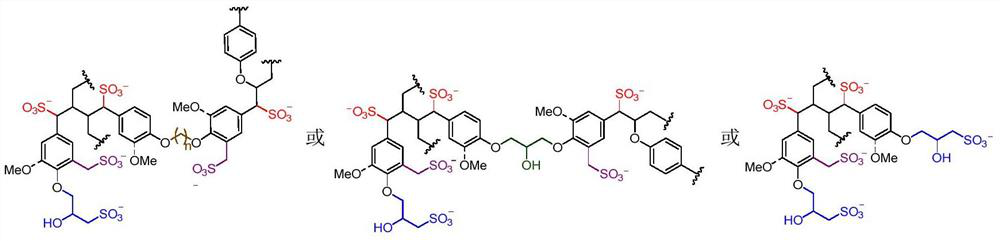

Multi-modified lignosulfonate dye dispersant and preparation method thereof

A technology of lignosulfonate and dye dispersant, which is applied in the direction of dyeing, textile and paper making, etc., can solve the problems of low reduction rate fiber stain, strong reducibility to azo dyes, poor high temperature stability, etc., and achieves excellent High temperature stability, cheap raw materials, and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

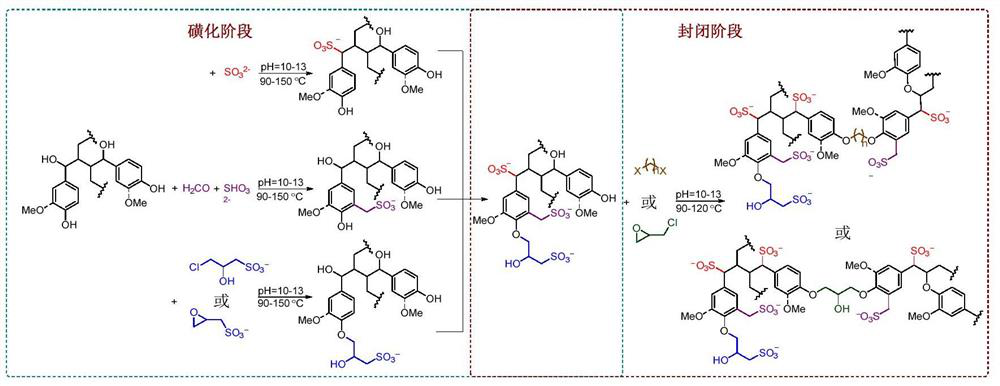

Method used

Image

Examples

Embodiment 1

[0033] Add 50 grams of alkali lignin to 500 mL of water, add NaOH to adjust the pH to 10 to dissolve the lignin, add 5 grams of sodium sulfite, react at 150 °C for 2 hours, add 5 grams of formaldehyde, adjust the temperature to 90 °C, and react for 2.5 hours, Then 20 g of dibromohexane was added to react for 2 h. After cooling to room temperature, the purified product was dialyzed against a dialysis bag with a molecular weight of 1000. Then, the solution after dialysis is subjected to vacuum rotary evaporation to remove most of the water, and finally the viscous solution after rotary evaporation is freeze-dried to finally obtain powdery multi-modified lignosulfonate.

Embodiment 2

[0035] Add 50 grams of alkali lignin to 500 mL of water, add NaOH to adjust the pH to 10 to dissolve the lignin, add 5 grams of sodium sulfite, react at 150 °C for 2 hours, and then add 25 grams of sodium 3-chloro-2-hydroxypropyl sulfonate , heated to 90°C, reacted for 2.5h, then added 12 grams of epichlorohydrin to react for 2h, cooled to room temperature, and purified the product by dialysis with a dialysis bag with a molecular weight of 1000. Then, the solution after dialysis is subjected to vacuum rotary evaporation to remove most of the water, and finally the viscous solution after rotary evaporation is freeze-dried to finally obtain powdery multi-modified lignosulfonate.

Embodiment 3

[0037] Add 50 grams of alkali lignin to 500 mL of water, add NaOH to adjust the pH to 10 to dissolve the lignin, add 5 grams of sodium sulfite, react at 150 °C for 2 hours, and add 25 grams of sodium 3-chloro-2-hydroxypropyl sulfonate. The temperature was raised to 90° C., the reaction was carried out for 2.5 hours, and 20 grams of 1,6-dibromohexane were added to react for 2 hours to obtain a modified lignosulfonate solution product. After cooling to room temperature, the purified product was dialyzed against a dialysis bag with a molecular weight of 1000. Then, the solution after dialysis is subjected to vacuum rotary evaporation to remove most of the water, and finally the viscous solution after rotary evaporation is freeze-dried to finally obtain powdery multi-modified lignosulfonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com