KTP crystal for quasi-phase matching device PPKTP and preparation method of KTP crystal

A quasi-phase and crystal technology, applied in the field of KTP crystal for quasi-phase matching device PPKTP and its preparation, can solve the problems of changing the surface composition and refractive index of KTP, increasing the difficulty of polarization, and inability to complete polarization inversion, etc. Improved optical uniformity, low conductivity, and low absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0045] A second aspect of the present application provides a method for preparing a KTP crystal with low conductance, low absorption, and high optical uniformity according to the first aspect of the present invention, wherein the preparation steps of the KTP crystal include:

[0046] (1) Synthesize the raw material of KTP crystal, synthesize K 7 P 3 O 11 The raw materials and barium-containing compounds are put into a platinum crucible in the crystal growth furnace, heated and melted at 890-945 °C, and then stirred at this temperature for 45-65 hours to obtain a uniform and stable high-temperature solution;

[0047] (2) Put in KTP seed crystals, and then reduce the temperature to the saturation temperature of 875-920 °C at a rate of 15-50°C / h; after putting in the seed crystals, cooling at a higher speed can reduce the amount of seed crystals dissolved, At the same time, the defects that may exist on the surface of the seed crystal are eliminated, and the quality of the grow...

Embodiment 1

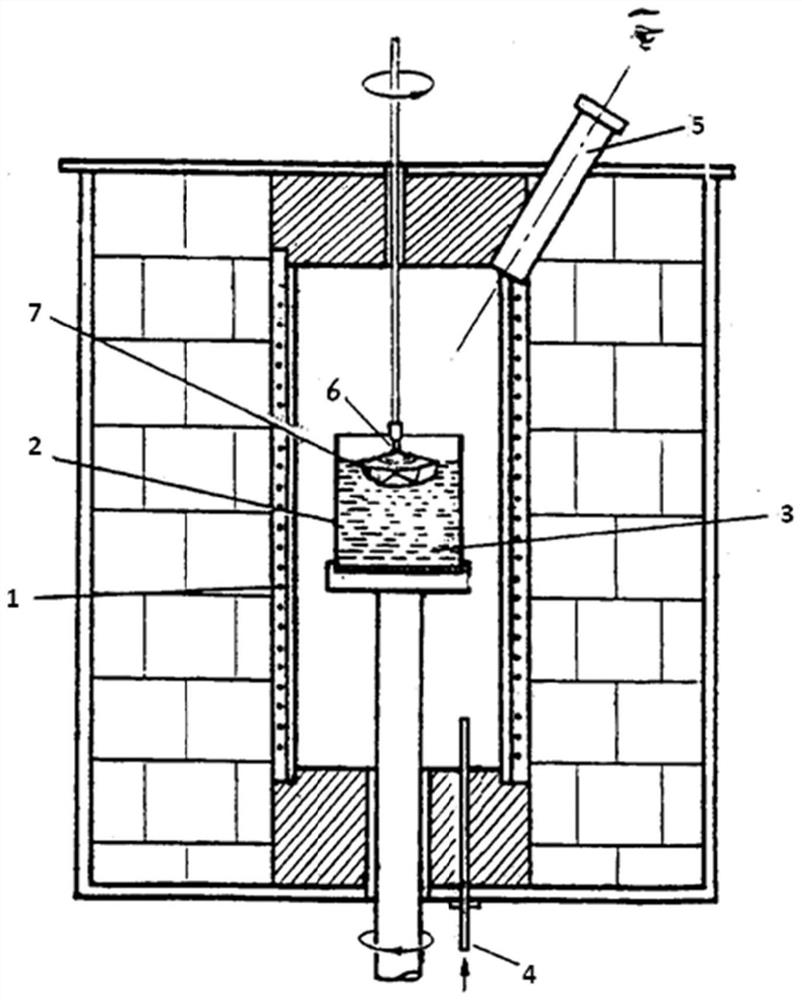

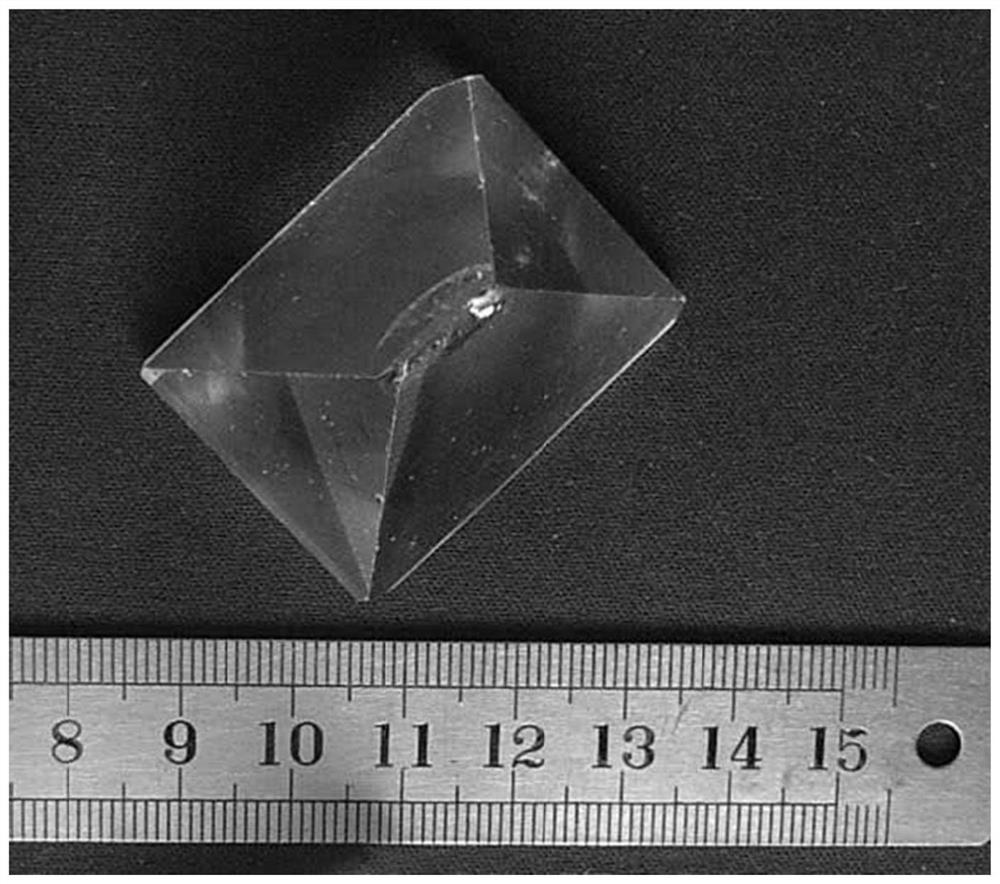

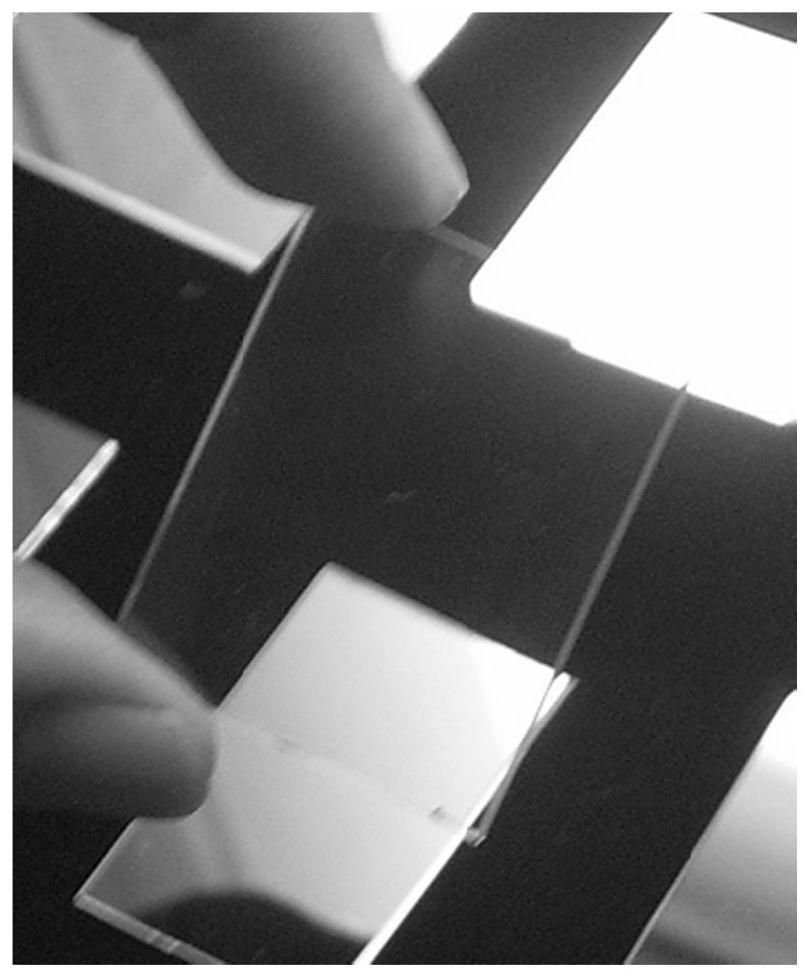

[0063] use figure 1 The crystal growth furnace shown contains 952.1 g of KH in a 4N (99.99%) pure platinum crucible with a diameter of 155 mm, a height of 120 mm and a thickness of 2 mm. 2 PO 4 , 559.0g of TiO 2 , 1668.3g of K 2 HPO 4 , 220.6g of K 2 CO 3 and 34.5g of BaCO 3 . The furnace temperature was raised to 945°C, the raw materials were melted, the temperature was maintained for 48h, and the crucible was rotated to form a uniform and stable high-temperature solution. Insert the KTP seed crystal so that it is in contact with the liquid surface. The temperature was lowered to the saturation point of 920°C within 30min, and then lowered to 880°C at a rate of 0.01-0.15°C / h, and water-white KTP crystals with a size of 40mm×35mm×30mm were grown, see figure 2 , after orientation, cutting and polishing, a z-cut KTP wafer with a size of 35mm × 25mm × 1mm is obtained, that is, the wafer obtained by cutting perpendicular to the z-axis direction of the crystal, see imag...

Embodiment 2

[0065] use figure 1 The crystal growth furnace shown contains 882.1 g of KH in a 4N-purity platinum crucible with a diameter of 155 mm, a height of 120 mm, and a thickness of 2 mm. 2 PO 4 , 517.9g of TiO 2 , 1766.4g of K 2 HPO 4 , 233.6g of K 2 CO 3 and 20.5g of BaF 2 . The furnace temperature was raised to 920°C, the raw materials were melted, the temperature was maintained for 48h, and the crucible was rotated to form a uniform and stable high-temperature solution. Insert the KTP seed crystal so that it is in contact with the liquid surface. The temperature was lowered to the saturation point of 890°C within 45min, and then lowered to 840°C at a rate of 0.01-0.2°C / h, and a water-white KTP crystal with a size of 40mm×35mm×30mm was grown, and the size was obtained by orientation, cutting and polishing. It is a z-cut KTP wafer of 35mm×25mm×1mm, and its conductivity is measured to be 3×10 -10 S / cm, optical uniformity Δn is 4.5×10 -6 / cm, 532nm laser absorption is 5500...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com