Preparation method of polysaccharide-active protein/polypeptide-based active hydrogel microspheres with high cell affinity

A technology of hydrogel microspheres and active proteins, which is applied in the field of preparation of polysaccharide-active protein/polypeptide-based active hydrogel microspheres with high cell affinity, and can solve the problem of insufficient cell affinity of polysaccharide materials, etc. problems, to achieve the effect of improving biological safety, avoiding toxic and side effects, and promoting normal tissue formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of Hyaluronic Acid-Lysozyme Hydrogel Microspheres

[0038] Solution 1: Accurately weigh 0.12g of sodium hyaluronate powder (Mw=40kDa) and dissolve it in 2.5g of phosphate buffer solution (pH=7.2), stir evenly to a clear and transparent solution.

[0039] Solution 2: Accurately weigh 0.24 g of lysozyme powder, dissolve it in 2.5 g of phosphate buffer (pH=7.2), and stir evenly to a clear and transparent solution.

[0040] After the solution 1 and the solution 2 were mixed and stirred to form a homogeneous phase, 0.02 g of DMTMM powder was added thereto, and the mixture was continued to be uniformly stirred to obtain a gel-forming solution 3.

[0041] Solution 4: Add 0.75g of surfactant Span-80 to 50g of dimethicone, and stir to a clear and transparent solution at room temperature.

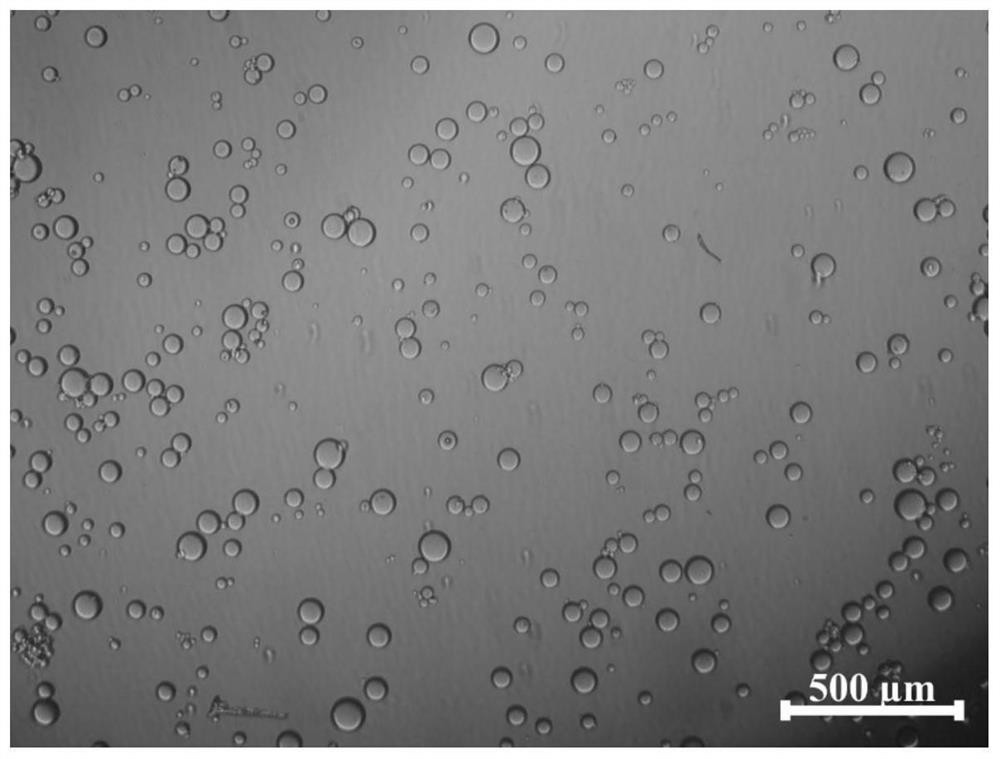

[0042] At room temperature, solution 3 was added dropwise to solution 4, and the stirring speed was 400 rpm. After 24 hours of reaction at room temperature, the superna...

Embodiment 2

[0043] Example 2: Hyaluronic acid-lysozyme hydrogel microsphere particle size range test

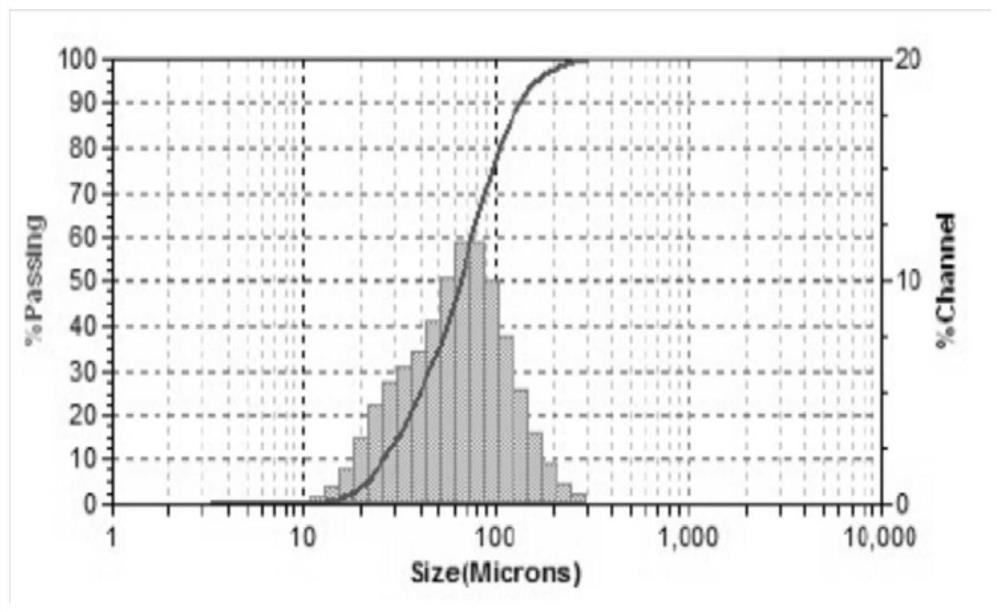

[0044] The gel spheres in Example 1 were soaked in phosphate buffer (pH=7.2), and an appropriate amount was drawn to measure the particle size distribution of the gel spheres. The size of the gel spheres is 20-100 μm, and the particle size is normally distributed, as shown in the appendix. figure 2 shown.

Embodiment 3

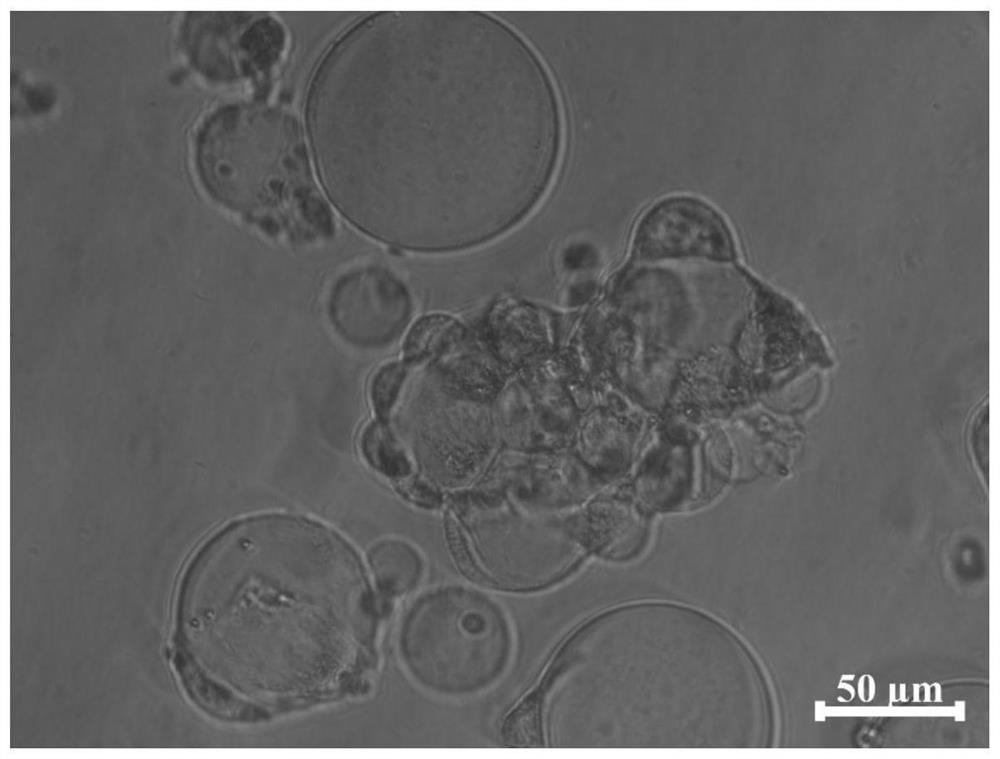

[0045] Example 3: Observation of the growth of L929 cells on the surface of hyaluronic acid-lysozyme hydrogel microspheres

[0046] The gel spheres in Example 1 were sterilized with 75% ethanol solution, and fibroblasts were planted on the surface of the gel spheres. After 1 day, the cells adhered and grew on the surface of the material. image 3 As shown, the fibroblasts adhered to the surface of the gel spheres exhibited both spindle and round morphologies.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com