Preparation method of submicron small primary crystal alpha aluminum oxide for CMP (Chemical Mechanical Polishing) solution

A ɑ-alumina, sub-micron technology, applied in the field of sub-micron small primary crystal ɑ-alumina preparation, can solve the problems of high nano-scale ɑ-alumina, high grinding costs, and large surface damage to the polished object, reducing Difficulty in grinding and impurity removal, inhibiting the growth of original crystals, and the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

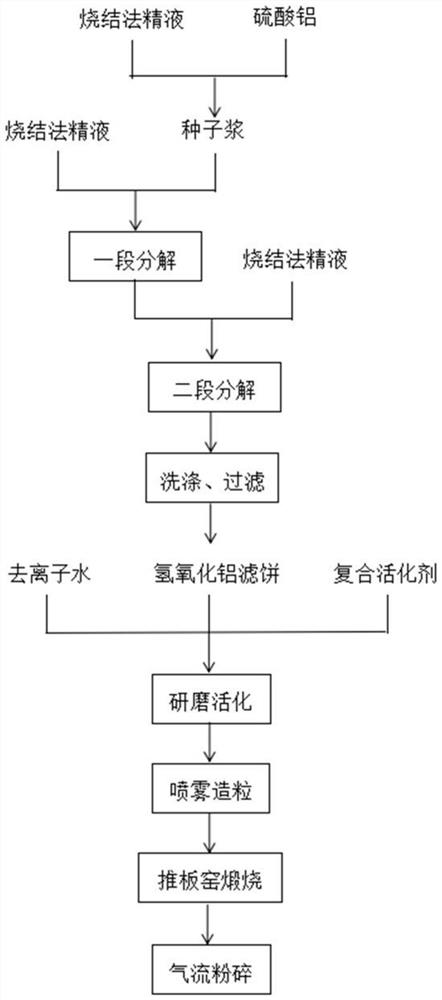

[0029] A kind of preparation method of submicron-level small primary crystal ɑ aluminum oxide for CMP polishing liquid, comprising the following steps:

[0030] (1) Aluminium sulfate and sintered semen are rapidly and vigorously stirred under certain conditions to obtain a highly active ultrafine seed slurry, which is then aged for use; then the aged seed slurry is added to the sintered semen as a crystal seed for a period of time. Decompose, control the decomposition temperature to be 50°C-60°C, the seed ratio is 15%-30%, and the seed ratio is the Al in the seed slurry and the semen of the sintering method 2 O 3 Then, the slurry after the first stage of decomposition is added to the semen of the sintering method as a crystal seed, and the second stage of decomposition is carried out. For a period of decomposition slurry and sintering method of Al in semen 2 O 3 The mass ratio of D50 = 0.5μm-1.2μm, the purity of > 99.6% aluminum hydroxide;

[0031] (2) washing the aluminum...

Embodiment 1

[0043] A kind of preparation method of submicron-level small primary crystal ɑ aluminum oxide for CMP polishing liquid, comprising the following steps:

[0044](1) Under certain conditions, aluminum sulfate and sintered semen are rapidly and vigorously stirred to prepare a seed slurry, and the seed slurry is added to the sintered semen as a crystal seed, and then decomposed for a period of time, and then a segment of decomposed slurry is added to the sintered semen as a The crystal seed is decomposed in two stages, wherein the decomposition temperature is 55° C., the ratio of the first stage seed is 20%, and the ratio of the second stage seed is 6%, to prepare aluminum hydroxide with D50=1.0 μm and purity > 99.6%;

[0045] (2) washing the aluminum hydroxide decomposed in step (1) to neutrality, and then preparing the filtered cake and deionized water into aluminum hydroxide slurry with a solid content of 20%, in the slurry A dispersant is also added, and the added amount of th...

Embodiment 2

[0051] A kind of preparation method of submicron-level small primary crystal ɑ aluminum oxide for CMP polishing liquid, comprising the following steps:

[0052] (1) Under certain conditions, aluminum sulfate and sintered semen are rapidly and vigorously stirred to prepare a seed slurry, and the seed slurry is added to the sintered semen as a crystal seed, and then decomposed for a period of time, and then a segment of decomposed slurry is added to the sintered semen as a The crystal seed is decomposed in two stages, wherein the decomposition temperature is 55° C., the ratio of the first stage seed is 20%, and the ratio of the second stage seed is 8%, to prepare aluminum hydroxide with D50=0.8 μm and purity > 99.6%;

[0053] (2) washing the aluminum hydroxide decomposed in step (1) to neutrality, then preparing the filtered cake and deionized water into aluminum hydroxide slurry with a solid content of 23%, in the slurry A dispersant is also added, and the added amount of the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com