Phosphonic acid group-containing polymer viscosity reducer and preparation method thereof

A polymer, phosphonic acid-based technology, applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of limiting the ability of polymers to resist salt and calcium, the total yield of the synthesis reaction is low, and the content of phosphorus elements is limited, etc. Achieving good viscosity reduction effect, simple synthesis process, strong resistance to salt and high-valent metal ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

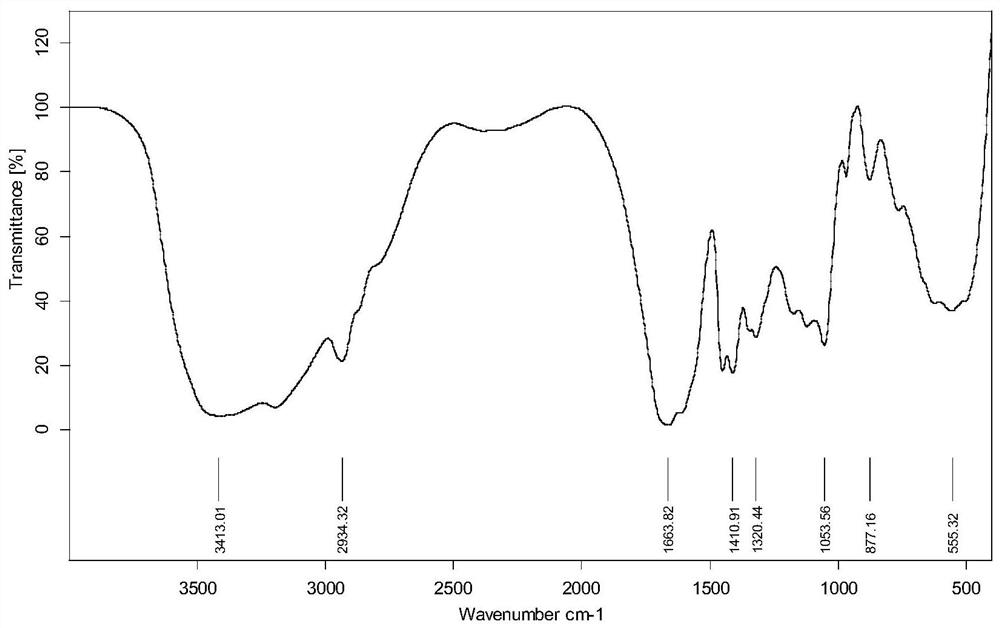

Image

Examples

preparation example Construction

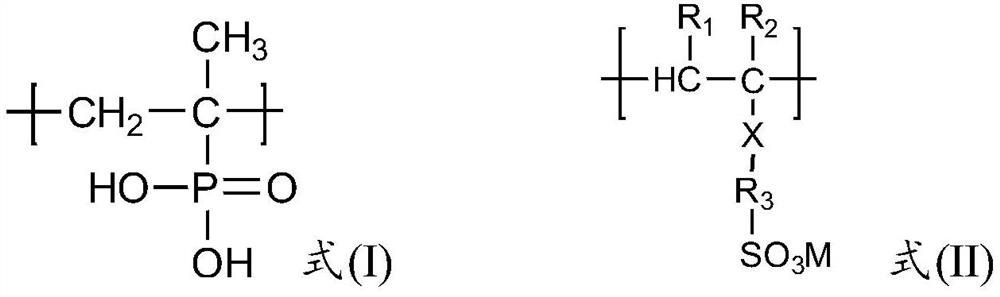

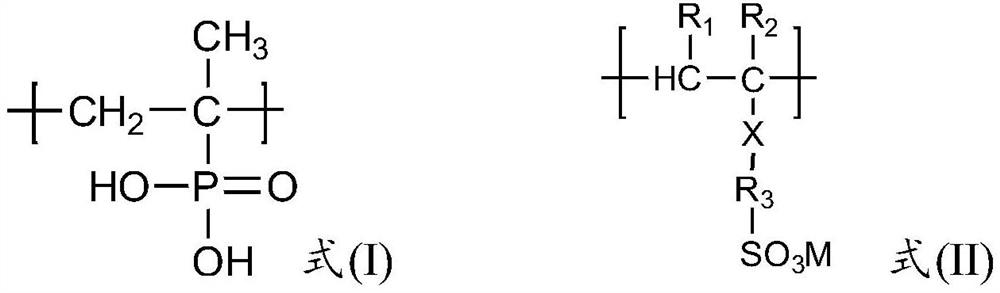

[0034] The invention provides a preparation method of a phosphonic acid group-containing polymer viscosity reducer, comprising the following steps:

[0035] It is obtained by polymerizing the isopropenyl phosphoric acid monomer A and the sulfonic acid group-containing monomer B in the presence of an initiator and a molecular weight regulator.

[0036] The preparation method is preferably specifically:

[0037] The isopropenylphosphonic acid monomer A and the sulfonic acid group-containing monomer B are mixed and dissolved to prepare an aqueous solution according to the mass ratio of (0.2-0.65): (0.35-0.8).

[0038] The propylene phosphoric acid monomer of the present invention is IPPA, which is not limited in the present invention, as long as those skilled in the art are familiar with it.

[0039] Isopropylene phosphonic acid is an organic phosphonic acid. Phosphonic acid polymers have excellent calcium resistance and better temperature and salt resistance than sulfonate pol...

Embodiment 1

[0057] Mix isopropenylphosphonic acid (IPPA) and 2-acrylamido-2-methylpropanesulfonic acid (AMPS) according to the substance ratio of 35%:65% to prepare a monomer mixture with a mass fraction of 30% aqueous solution, and isopropanol (IPA) accounting for 1% of the total mass of the monomer mixture was added to the aqueous monomer mixture solution, and the temperature was raised to 60°C. Then, potassium persulfate, which accounts for 1.5% of the total monomer mass, was dissolved in clear water, added to the reaction system, and then the system was heated to 75 °C for 5 h. After the reaction, the pH value was adjusted to 8 with sodium hydroxide to obtain micro Viscous liquid, dried and crushed to contain organic phosphoric acid viscosity reducer.

Embodiment 2~8

[0059] According to the method of embodiment 1, prepare organic phosphonic acid polymer viscosity reducer respectively; Different formulas and conditions are shown in Table 1:

[0060] Material dosage and reaction conditions of polymerization reaction in the embodiment 2-9 of table 1

[0061]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com