Lithium air battery gel air positive electrode, preparation method and lithium air battery

A lithium-air battery and air positive electrode technology, applied in battery electrodes, fuel cell half-cells, secondary battery-type half-cells, circuits, etc., can solve the problems of long time, low ion conductivity, complex design, etc. problems, to achieve the effects of easy industrial production, simple preparation method, and reduced polarization increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~15

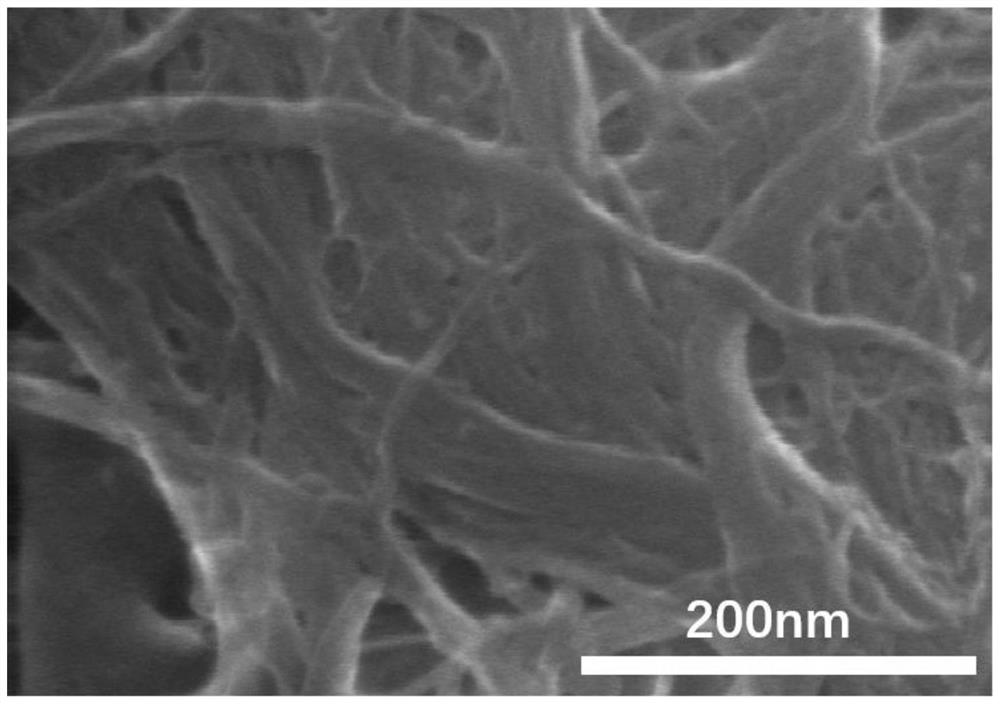

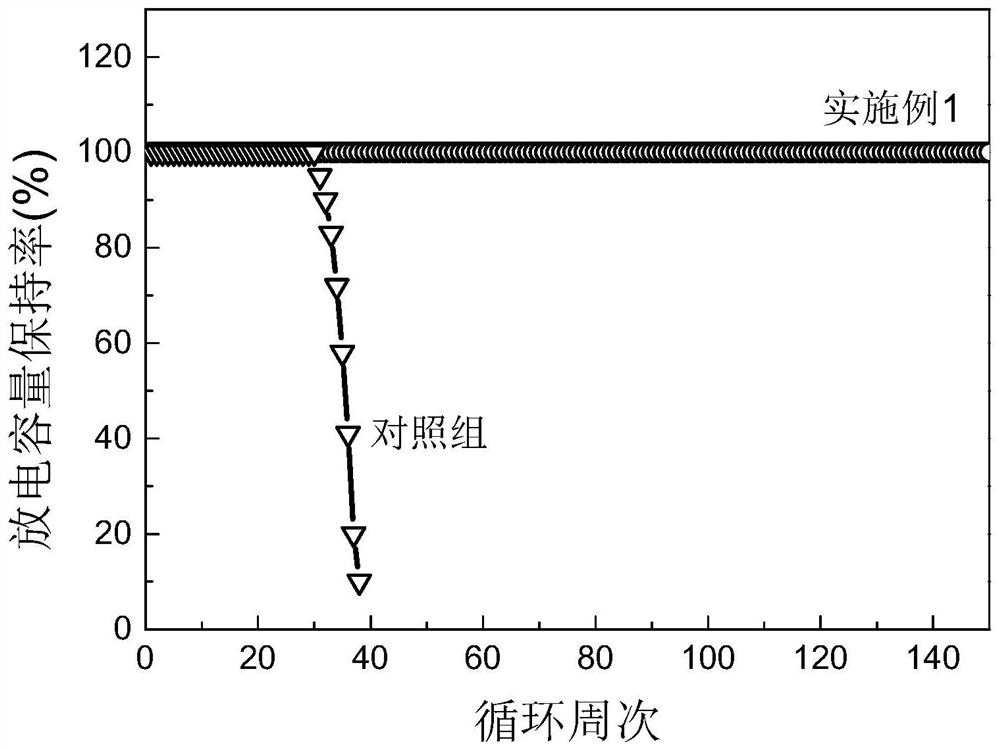

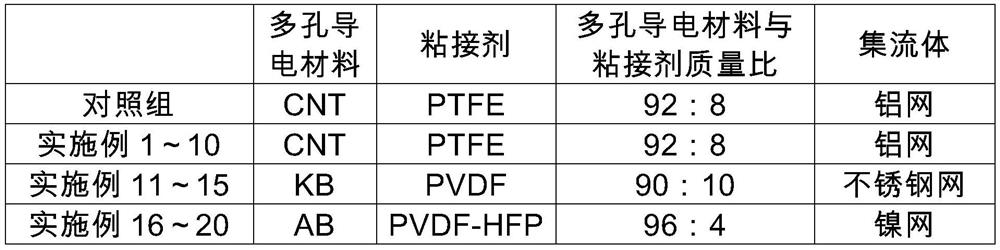

[0033] The lithium-air battery gel-air positive electrodes of Examples 1 to 15 are prepared from a current collector, a porous conductive material, a binder, a polymer monomer, a crosslinking agent, an initiator, a solvent, and a dispersant, and the initiator The molar ratio of agent and polymer monomer is 1:100; wherein,

[0034] The current collector in Examples 1-10 is selected from aluminum mesh, the porous conductive material is selected from carbon nanotubes (CNT), the adhesive is selected from polytetrafluoroethylene (PTFE), and the porous conductive material and the adhesive are selected. The mass ratio of the bonding agent is 92:8 (that is, the mass percentage of the porous conductive material is 92%, and the mass percentage of the binder is 8%), and the current collector in Examples 11 to 15 is made of stainless steel mesh , the porous conductive material is selected from Ketjen carbon (KB), the adhesive is selected from polyvinylidene fluoride (PVDF), and the mass r...

Embodiment 16~20

[0037] The lithium-air battery gel-air cathodes of Examples 16-20 are prepared from current collectors, porous conductive materials, binders, polymer monomers, auxiliary polymer monomers, cross-linking agents, initiators, solvents, and dispersants. into, and the molar ratio of the initiator and the polymer monomer is 1:100; wherein,

[0038] The current collector in Examples 16-20 is selected from nickel mesh, the porous conductive material is selected from acetylene black (AB), the adhesive is selected from polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP), and the The mass ratio of the porous conductive material and the binder is 96:4 (that is, the mass percentage of the porous conductive material is 96%, and the mass percentage of the binder is 4%); The polymer monomer and the associated agent are respectively methyl methacrylate and triethylene glycol dimethacrylate, and the auxiliary polymer monomers in Examples 16 to 20 are respectively acrylonitrile, styrene, and m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com