Preparation method of ampelopsis grossedentata extract

A rattan tea extract and rattan tea technology are applied in the field of preparation of rattan tea extracts, which can solve the problems of destroying biological active substances, solvent residues, and reducing the content of rattan tea effective substances, and achieve low temperature, stable properties and product stability. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

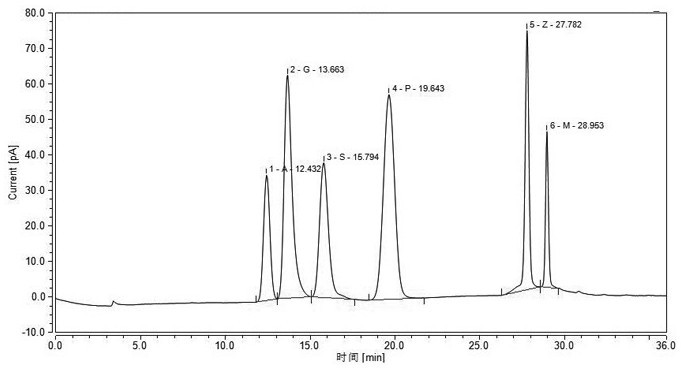

Image

Examples

Embodiment 1

[0042] A preparation method of vine tea extract, comprising the following steps:

[0043] S1. Weigh 40g of rattan tea, add 400g of deionized water, then add 0.4g of combined enzymes for enzymolysis for 40min, and filter to obtain filter residue A and filtrate A, wherein the combined enzymes include pectinase, cellulase, amylase, protease The mass ratio is 1:1:1:1;

[0044] S2, get the filter residue A obtained in the above-mentioned S1 and dissolve it in 400g deionized water, add 0.8g citric acid-disodium hydrogen phosphate, adjust the pH value to be 2.5, high-pressure microwave treatment, filter to obtain filter residue B and filtrate B, wherein, high pressure The pressure of microwave treatment is 400KPa, and the time is 10 min;

[0045] S3, get the filter residue B obtained in above-mentioned S2 and be dissolved in 400g deionized water, add 0.8g citric acid-disodium hydrogen phosphate, adjust pH value to be 8, high pressure microwave treatment, filter to obtain filter resi...

Embodiment 2

[0050] A preparation method of vine tea extract, comprising the following steps:

[0051] S1. Weigh 40g of vine tea, add 400g of deionized water, then add 1.2g of combined enzymes for enzymolysis for 40min, and filter to obtain filter residue A and filtrate A, wherein the combined enzymes include pectinase, cellulase, amylase, protease The mass ratio is 1:1:1:1;

[0052] S2, get the filter residue A obtained in above-mentioned S1 and be dissolved in 400g deionized water, add 0.8g citric acid-disodium hydrogen phosphate, adjust the pH value to be 3, high-pressure microwave treatment, filter to obtain filter residue B and filtrate B, wherein, high pressure The pressure of microwave treatment is 400KPa, and the time is 10 min;

[0053] S3, get the filter residue B obtained in above-mentioned S2 and be dissolved in 400g deionized water, add 0.8g citric acid-disodium hydrogen phosphate, adjust the pH value to be 8.5, high pressure microwave treatment, filter to obtain filter resid...

Embodiment 3

[0058] A preparation method of vine tea extract, comprising the following steps:

[0059] S1, weigh 40g of vine tea, add 400g of ethanol solution with a mass concentration of 60%, then add 1.2g combined enzyme enzymolysis for 40min, filter to obtain filter residue A and filtrate A, wherein, the combined enzyme includes pectinase, cellulase, The mass ratio of amylase and protease is 1:1:1:1;

[0060] S2, get the filter residue A obtained in above-mentioned S1 and be dissolved in 400g deionized water, add 0.8g citric acid-disodium hydrogen phosphate, adjust the pH value to be 3, high-pressure microwave treatment, filter to obtain filter residue B and filtrate B, wherein, high pressure The pressure of microwave treatment is 400KPa, and the time is 10 min;

[0061] S3, get the filter residue B obtained in above-mentioned S2 and be dissolved in 400g deionized water, add 0.8g citric acid-disodium hydrogen phosphate, adjust the pH value to be 8.5, high pressure microwave treatment, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap