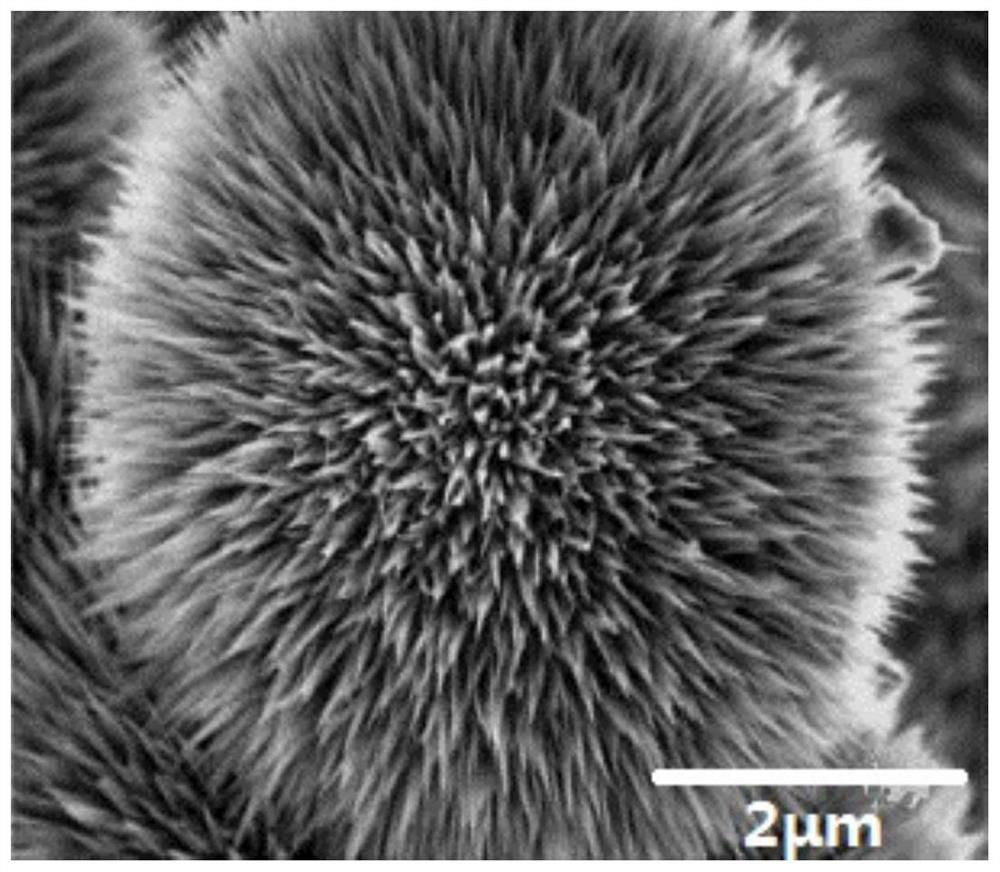

Preparation method and application of sea urchin-shaped lithium cobalt oxide

A technology of lithium cobalt oxide and cobalt salt, which is applied in the direction of chemical instruments and methods, cobalt compounds, structural parts, etc., can solve the problems of small electrolyte infiltration area, insufficient contact, and large battery impedance, so as to facilitate infiltration and penetration. Transport of lithium ions, good rate characteristics and cycle stability, and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

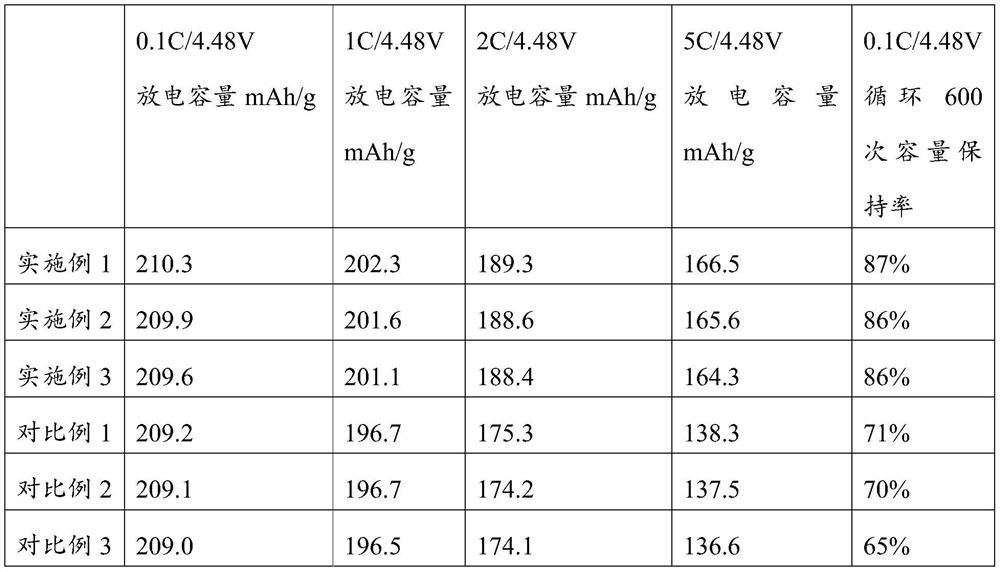

Embodiment 1

[0036] In this embodiment, a sea urchin-shaped lithium cobalt oxide positive electrode material is prepared, and the specific process is as follows:

[0037] Step 1, preparation concentration is the cobalt chloride solution of 0.05mol / L;

[0038] Step 2, adding the cobalt chloride solution in step 1 into the autoclave, and the amount added is 3 / 5 of the volume of the reactor;

[0039] Step 3, in reactor, add ammonium fluoride, urea and benzoyl peroxide, make the concentration of ammonium fluoride reach 0.15mol / L, urea concentration is 0.5mol / L, and benzoyl peroxide concentration is 0.02mol / L. L;

[0040] Step 4, after sealing the reaction kettle, heat it to 90°C and maintain the reaction temperature for 12h;

[0041] Step 5, after the reaction is completed, the solid-liquid separation is performed, and the obtained solid is washed with ethanol first, and then washed with pure water;

[0042] Step 6, after the washing product is dried, it is calcined for 2 hours in an air at...

Embodiment 2

[0045] In this embodiment, a sea urchin-shaped lithium cobalt oxide positive electrode material is prepared, and the specific process is as follows:

[0046] Step 1, preparation concentration is the cobalt sulfate solution of 0.5mol / L;

[0047] Step 2, adding the cobalt sulfate solution in step 1 into the autoclave, and the amount added is 70% of the volume of the reactor;

[0048] Step 3, in the reactor, add ammonium fluoride, urea and di-tert-butyl peroxide, make the concentration of ammonium fluoride reach 1.0mol / L, urea concentration is 2.5mol / L, and the concentration of di-tert-butyl peroxide is 0.022mol / L;

[0049] Step 4, after sealing the reaction kettle, heat it to 100°C and maintain the reaction temperature for 10h;

[0050] Step 5, after the reaction is completed, the solid-liquid separation is performed, and the obtained solid is washed with ethanol first, and then washed with pure water;

[0051] Step 6, after the washing product is dried, it is calcined for 4 ...

Embodiment 3

[0054] In this embodiment, a sea urchin-shaped lithium cobalt oxide positive electrode material is prepared, and the specific process is as follows:

[0055] Step 1, preparation concentration is 1.0mol / L cobalt nitrate solution;

[0056] Step 2, adding the cobalt nitrate solution in step 1 into the autoclave, and the amount added is 4 / 5 of the volume of the reactor;

[0057] Step 3, in reactor, add ammonium fluoride, urea and lauroyl peroxide, make the concentration of ammonium fluoride reach 2.0mol / L, urea concentration is 5.0mol / L, and the concentration of lauroyl peroxide is 0.025mol / L ;

[0058] Step 4, after sealing the reaction kettle, heat it to 110°C and maintain the reaction temperature for 8h;

[0059] Step 5, after the reaction is completed, the solid-liquid separation is performed, and the obtained solid is washed with ethanol first, and then washed with pure water;

[0060] Step 6, after the washing product is dried, it is calcined for 6 hours in an air atmosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com