Zero-discharge treatment system and method for synthetic ammonia and ethylene glycol wastewater

A treatment system, ethylene glycol technology, applied in the field of synthetic ammonia and ethylene glycol wastewater zero-discharge treatment system, can solve problems such as service life decline, performance decline, reverse osmosis membrane pollution, etc., to save investment, reduce water volume, and improve use efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

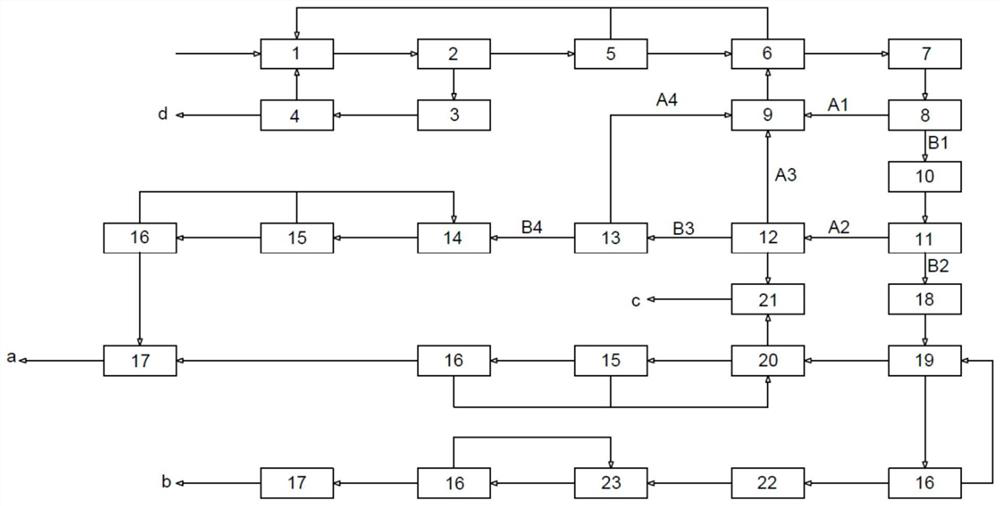

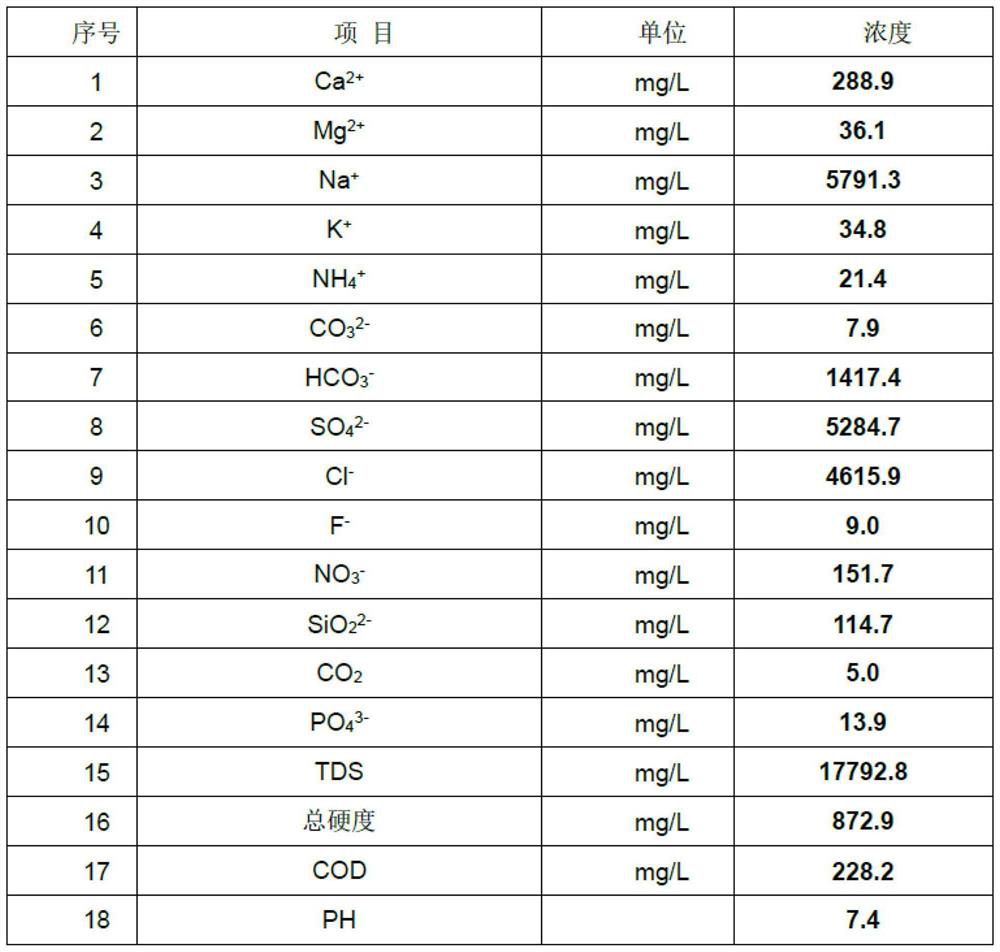

[0035] The present application relates to a zero-discharge treatment system for synthetic ammonia and ethylene glycol wastewater. The system includes a pretreatment unit, a nanofiltration unit and a crystallization unit. The pretreatment unit is used for removing heavy metal ions, silicon dioxide and hardness ions in the wastewater and sending them to the first reverse osmosis membrane module to obtain the first product water and the first concentrated water. The nanofiltration unit performs nanofiltration and salt separation on the first concentrated water processed by the first reverse osmosis membrane module through the nanofiltration membrane element, and obtains the second produced water and the second produced water after being processed by the nanofiltration unit. Concentrated water. The crystallization unit is used for crystallizing the second produced water and the second concentrated water treated by the nanofiltration unit. The first produced water enters the cryst...

Embodiment approach

[0038] According to a preferred embodiment, the high-density clarifier includes a conditioning tank and a high-density tank. The adjustment pool is equipped with online and local instruments. The inlet pipe of the regulating pool enters from above the design maximum water level. There is a sump at the bottom of the regulating pool. The conditioning pool is designed with a concrete top cover. In addition to the hard high-density pool, the high-density pool includes coagulation, clarification, neutralization and other systems in addition to online and on-site instruments. The complete de-hardening high-density tank design includes the process design of the system, related measuring instruments, dosing, sludge discharge, stirring, reflux, etc. In addition to the performance requirements of hard and high-density pools: different chemicals are set up with different stirring zones, the HRT from the water inflow to the end of flocculation is not less than 40min, and the HRT in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com