Method for preparing p-hydroxycinnamate by catalyzing lignin alcoholysis through enzymatic hydrolysis lignin-based hierarchical porous carbon-loaded molybdenum oxide

A lignin-based, molybdenum oxide technology, used in metal/metal oxide/metal hydroxide catalysts, preparation of organic compounds, catalyst activation/preparation, etc., can solve the difficulty of catalyst recovery, catalyst and product separation, etc. problem, to achieve the effect of low cost, high price and good matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

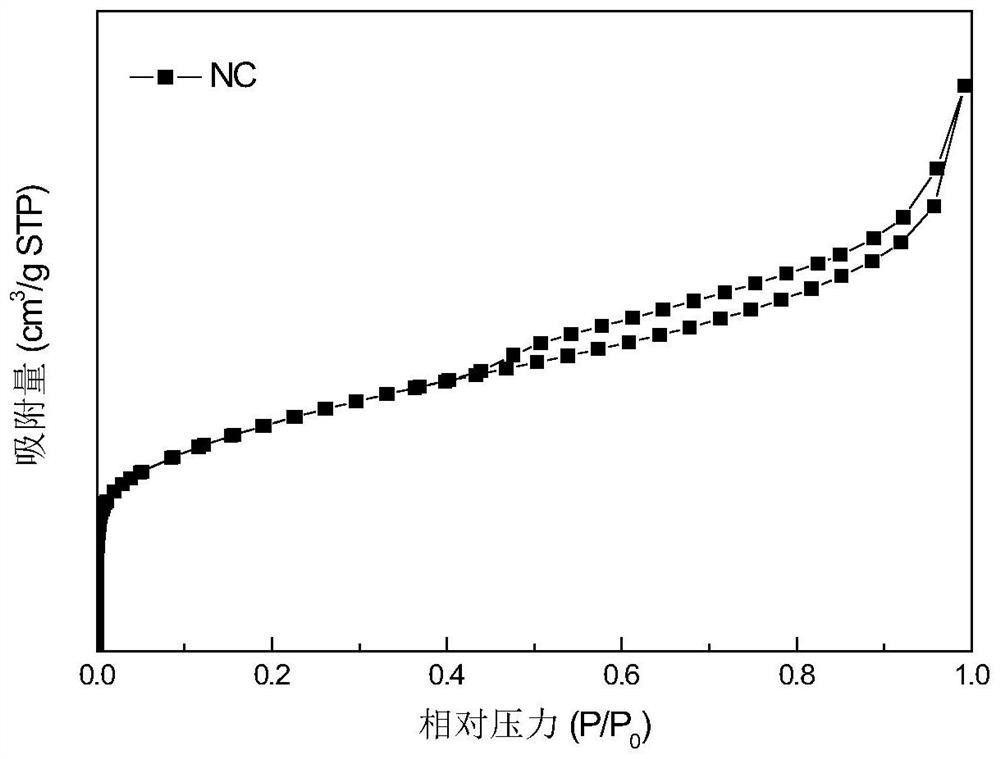

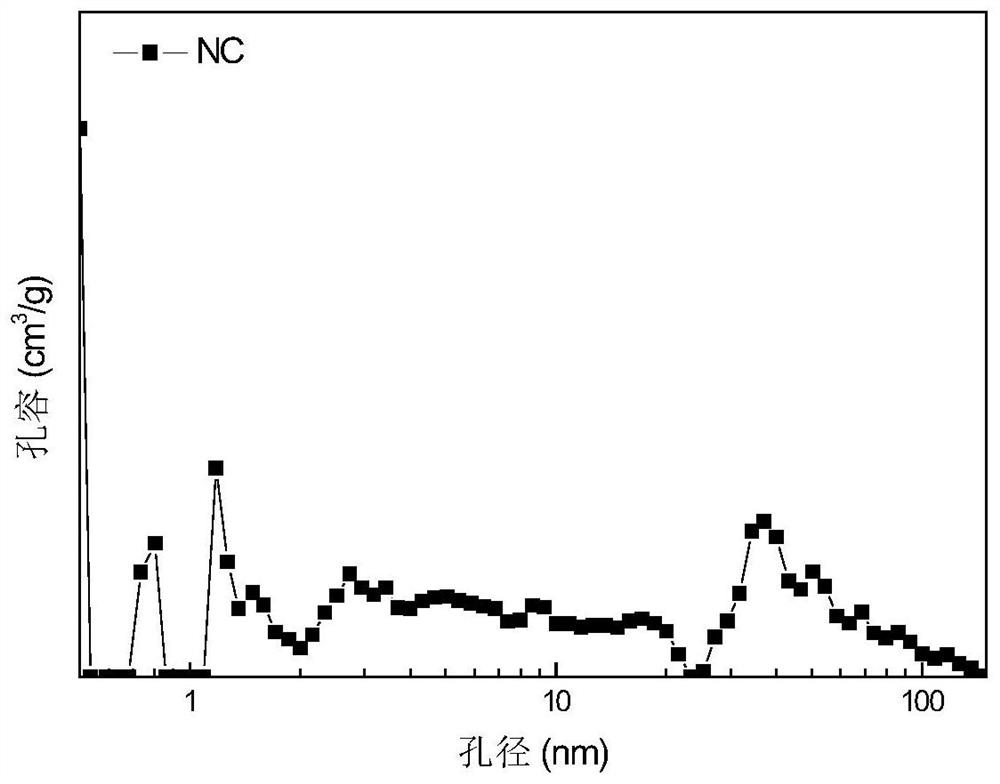

[0039] Example 1: Preparation of NC Carrier

[0040] Weigh 0.6g of industrial enzymatically hydrolyzed lignin (Shandong Longli Group), 0.1261g of melamine powder with a purity of 99.5%, and 1.4814g of ZnCl with a purity of 99% 2 Solid, 0.6360 g of KOH solid with a purity of 99%, the above four samples were dissolved in 50 mL of absolute ethanol, and ultrasonically treated for 0.5 h. After sonication, add 3g Mg(OH) 2 The powder and 50 mL of anhydrous ethanol were sonicated again for 0.5 h. Then, it was heated and stirred in an oil bath at 60 °C for 5 h, and after the end, the solvent was removed in a rotary evaporator and ground to obtain a yellow-brown powder, that is, the NC precursor. The NC precursor was calcined in a tube furnace at 800 °C for 140 min under an inert gas atmosphere, and cooled to room temperature naturally. Finally, pickle with 1mol / L nitric acid for 2h, and wash with water until neutral after pickling. After dry grinding, a black powdery NC carrier was...

Embodiment 2

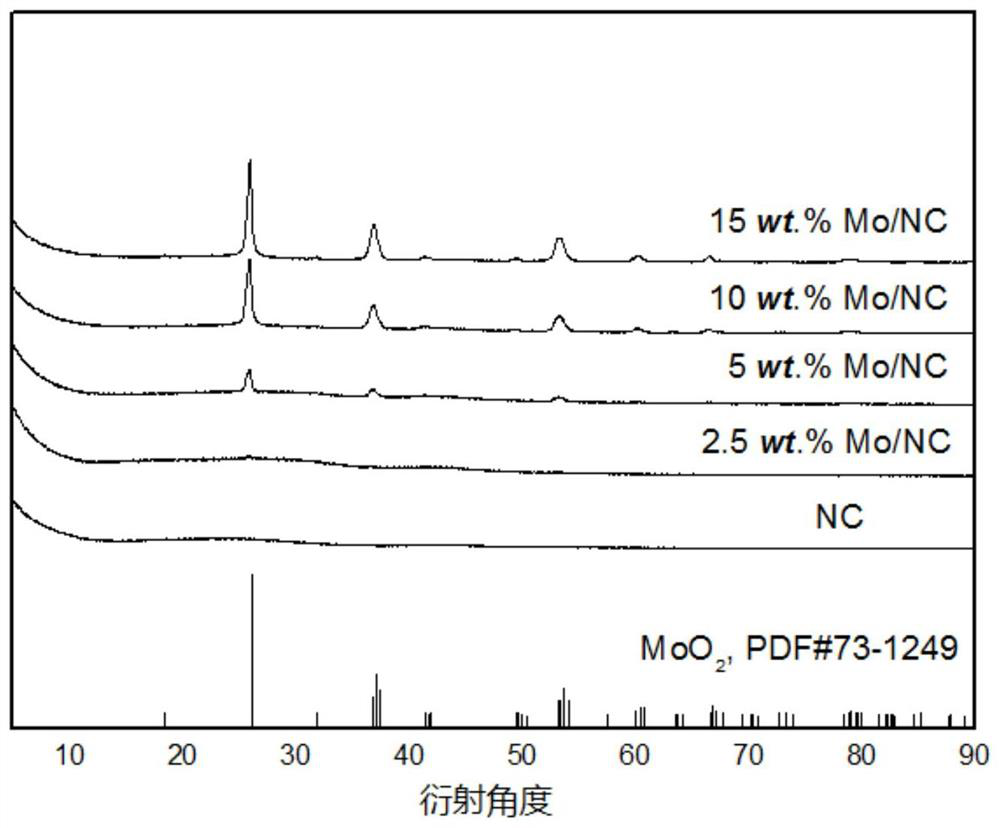

[0041] Example 2: Preparation of 10 wt.% Mo / NC catalyst

[0042] Weigh 0.2142g (NH 4 ) 6 Mo 7 O 24 ·4H 2 O, fully dissolved in 20 mL of deionized water, added 1 g of the NC carrier prepared in Example 1, soaked for 12 h, and dried at 80 °C for 12 h. In a tube furnace, N 2 The Mo / NC catalyst was obtained by calcining at 600 °C for 5 h under the atmosphere, and the loading of Mo was 10 wt.%.

Embodiment 3

[0043] Example 3: Preparation of 2.5 wt.% Mo / NC catalyst

[0044] Weigh 0.0480g (NH 4 ) 6 Mo 7 O 24 ·4H 2 O, fully dissolved in 20 mL of deionized water, added 1 g of the NC carrier prepared in Example 1, soaked for 12 h, and dried at 80 °C for 12 h. In a tube furnace, N 2 The Mo / NC catalyst was obtained by calcining at 600 °C for 5 h in an atmosphere with a Mo loading of 2.5 wt.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com