Liquid oxygen compatible phosphorus-containing epoxy resin system and preparation method thereof

An epoxy resin system, liquid oxygen technology, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve problems such as damage to epoxy resin properties, and achieve easy operation and preparation. Simple and feasible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

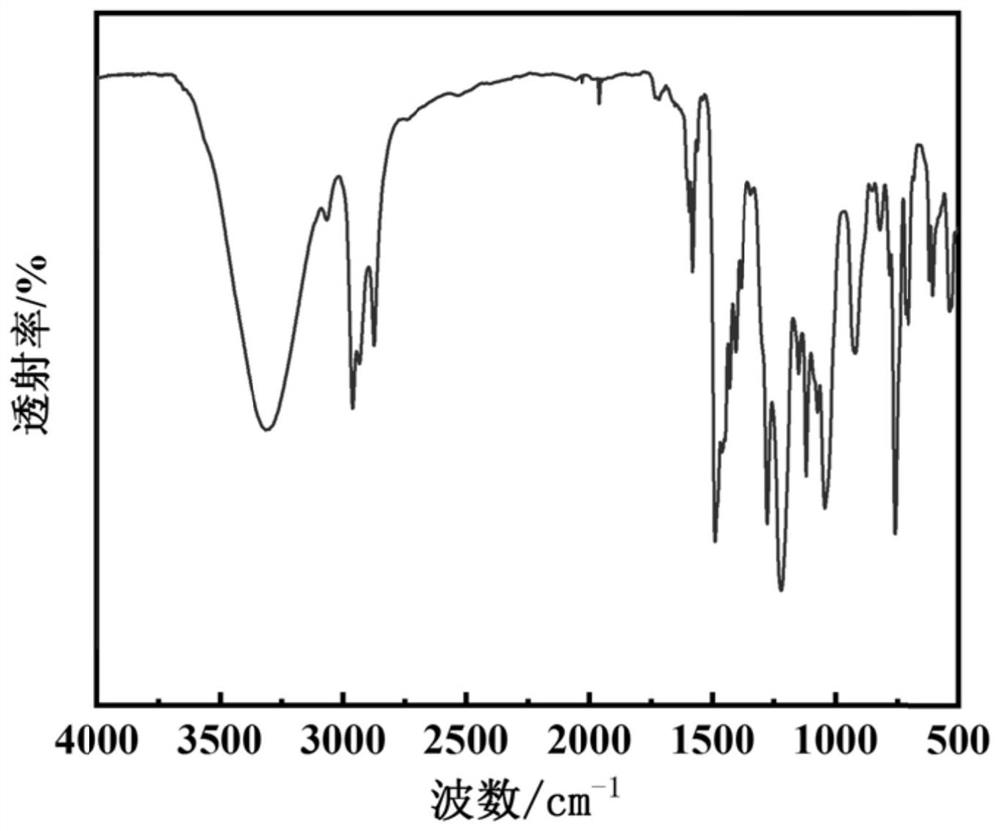

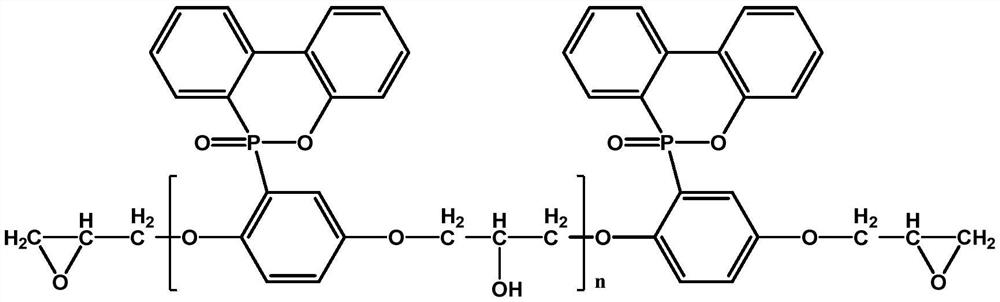

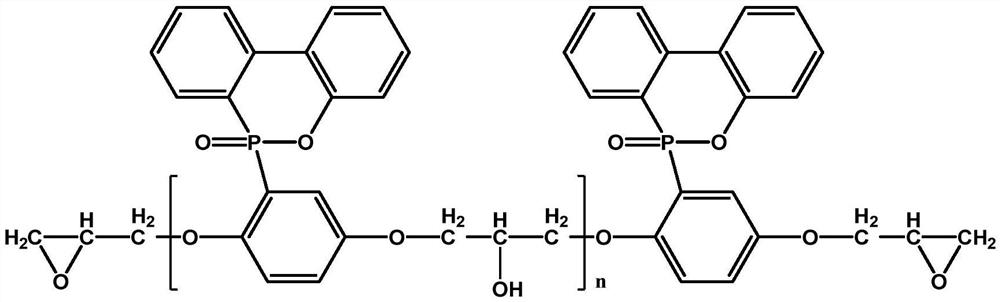

[0027] In a 250ml three-necked flask equipped with a stirring paddle, a reflux condenser and a nitrogen port, add 32.4g (0.1mol) of 10-(2,5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphorus Heterophenanthrene-10-oxide and 92.5g (1mol) epichlorohydrin, then add 0.01mol tetrabutylammonium bromide, under nitrogen protection, stir and react in an oil bath at 65°C for 6h, until the solution is clear and transparent ; Cool down to 50°C, add 20wt% sodium hydroxide (8g) solution dropwise with a constant pressure dropping funnel, the dropwise addition time is 1h, the reaction is 6h, the solution is clear and transparent; it is cooled to room temperature, and the organic solvent dichloromethane is used. Extraction, and wash with deionized water for 3 times to remove sodium chloride, until the aqueous phase is free of chloride ions (using silver nitrate solution to check); the final product is rotary distilled at 100 ° C to remove excess epichlorohydrin, organic solvent and water, and finally...

Embodiment 2

[0031] In a 250ml three-necked flask equipped with a stirring paddle, a reflux condenser and a nitrogen port, add 32.4g (0.1mol) of 10-(2,5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphorus Heterophenanthrene-10-oxide and 92.5g (1mol) epichlorohydrin, then add 0.005mol of tetrabutylammonium bromide, under nitrogen protection, stir and react in an oil bath at 65°C for 6h, until the solution is clear and transparent ; Cool down to 50°C, add 20wt% sodium hydroxide (8g) solution dropwise with a constant pressure dropping funnel, the dropwise addition time is 1h, the reaction is 6h, the solution is clear and transparent; it is cooled to room temperature, and the organic solvent dichloromethane is used. Extraction, and wash with deionized water for 3 times to remove sodium chloride, until the aqueous phase is free of chloride ions (using silver nitrate solution to check); the final product is rotary distilled at 100 ° C to remove excess epichlorohydrin, organic solvent and water, and fin...

Embodiment 3

[0033] In a 250ml three-necked flask equipped with a stirring paddle, a reflux condenser and a nitrogen port, add 32.4g (0.1mol) of 10-(2,5-dihydroxyphenyl)-10-hydro-9-oxa-10-phosphorus Heterophenanthrene-10-oxide and 92.5g (1mol) epichlorohydrin, then add 0.005mol of tetrabutylammonium bromide, under nitrogen protection, stir and react in an oil bath at 65°C for 6h, until the solution is clear and transparent ; Cool to 50°C, add 28wt% sodium hydroxide (8g) solution dropwise using a constant pressure dropping funnel, the dropwise addition time is 1h, the reaction is 6h, the solution is clear and transparent; it is cooled to room temperature, and the organic solvent dichloromethane is used. Extraction, and wash with deionized water for 3 times to remove sodium chloride, until the aqueous phase is free of chloride ions (using silver nitrate solution to check); the final product is rotary distilled at 100 ° C to remove excess epichlorohydrin, organic solvent and water, and finally...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com