Carbon quantum dot-loaded nano material lubricating additive and preparation method thereof

A technology of lubricating additives and carbon quantum dots, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of universal exploration of carbon quantum dots, to maintain shape and performance, avoid surfactants and modification The use of agents, to solve the effect of layer upon layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

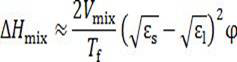

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0027] Wash the 25ml reactor lining with ultrapure water and dry it for later use. Weigh 1 g of citric acid and 0.5 g of n-phenyl-p-phenylenediamine into a beaker, add 16 ml of ultrapure water and stir to dissolve it, and then transfer it to the reaction kettle. The reaction kettle was capped and tightly sealed, put into a blast drying oven, and reacted at 150 ° C for 4 hours. Naturally cooled to room temperature with the furnace to obtain a yellow transparent liquid, that is, a solution containing carbon dots. The uniform suspension was filtered through a cellulose filter membrane (0.22 μm pore size), and furthe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dispersion coefficient | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

| dispersion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com