Microsphere frozen section as well as preparation method and application thereof

A technology of frozen section and microspheres, which is applied in microsphere preparation, microcapsule preparation, material analysis using wave/particle radiation, etc. It can solve problems such as lack of flatness, hole deformation, unsuitable porosity, etc. The effect of rolling, not easy to fragment, and shortening the soaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

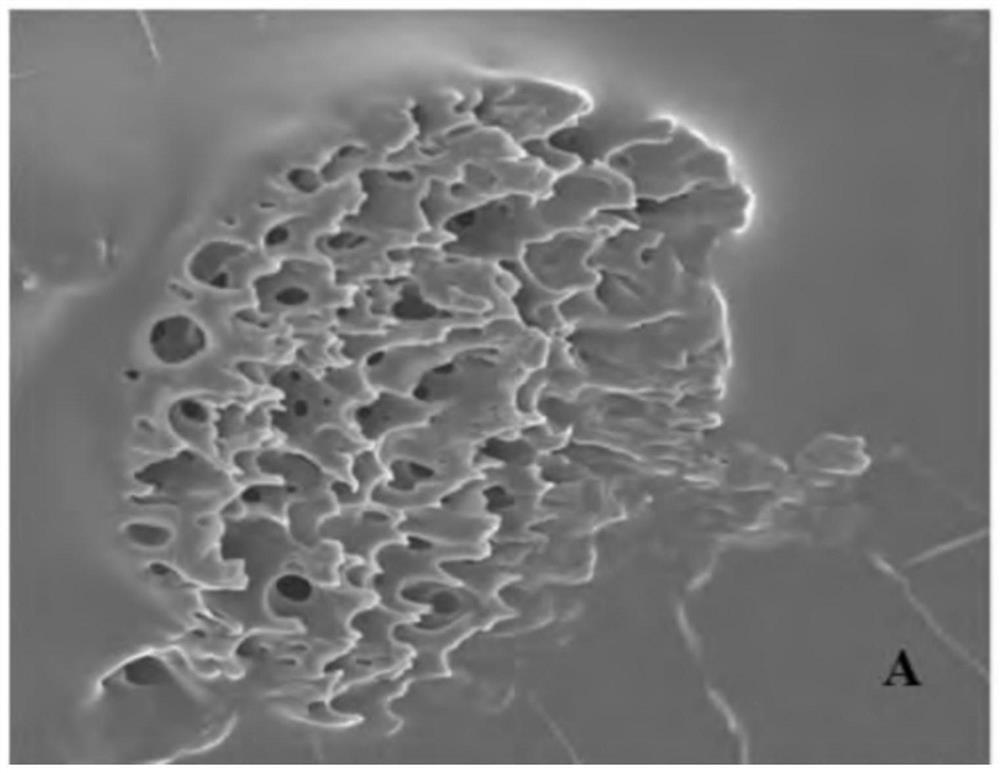

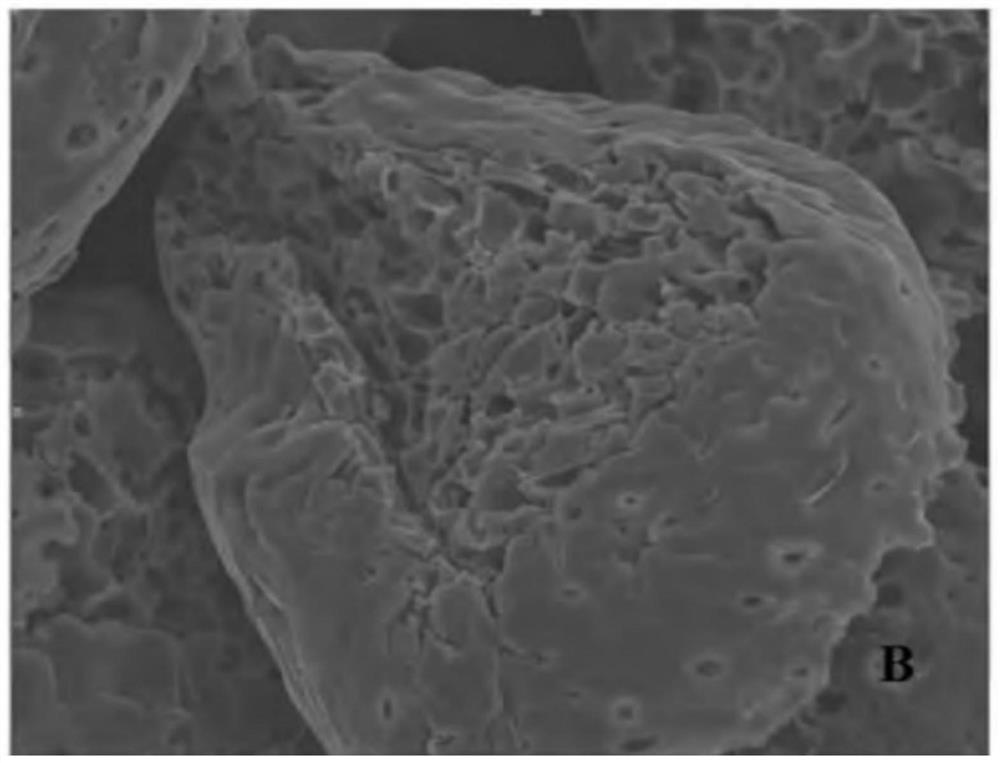

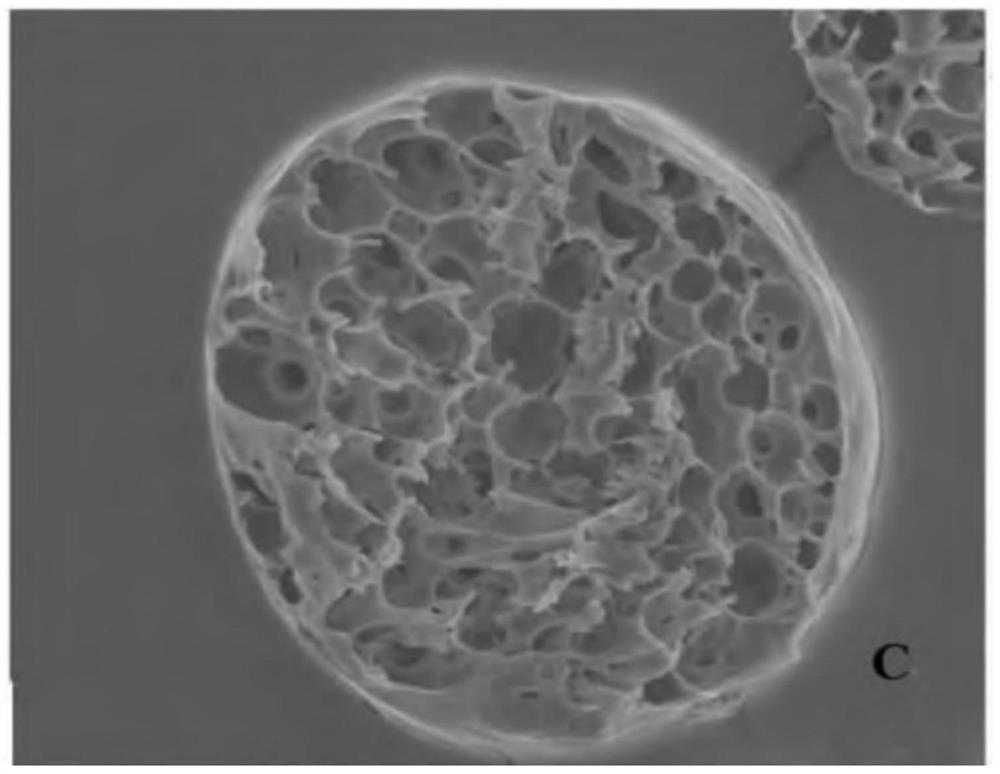

Image

Examples

Embodiment 1

[0043] The present embodiment provides a polylactic acid and polyglycolic acid microsphere cryosection and a preparation method thereof. The preparation method of the microsphere cryosection comprises the following steps:

[0044] (1) Preparation of microspheres:

[0045]Dissolve bovine serum albumin and sodium chloride in a certain concentration of poloxamer 188 solution to obtain an inner water phase. The inner water phase is added to the dichloromethane solution of polylactic acid and polyglycolic acid, and stirred at a high speed under low temperature conditions to form a primary emulsion. The colostrum was added to the polyvinyl alcohol solution and stirred for 10 min to form a double emulsion. The double emulsion is transferred to a large beaker containing a polyvinyl alcohol solution and slowly stirred to solidify the microspheres, collected by centrifugation, washed three times with water, and freeze-dried to prepare the microspheres.

[0046] (2) preparation of gela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com