Electromagnetic shielding iron-based composite material and preparation method thereof

An iron-based composite material and electromagnetic shielding technology, which is applied in the fields of magnetic/electric field shielding, electrical components, metal processing equipment, etc., can solve the problems of low strength, poor formability, and low strength of pure iron, so as to meet heat dissipation requirements and improve strength , Improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

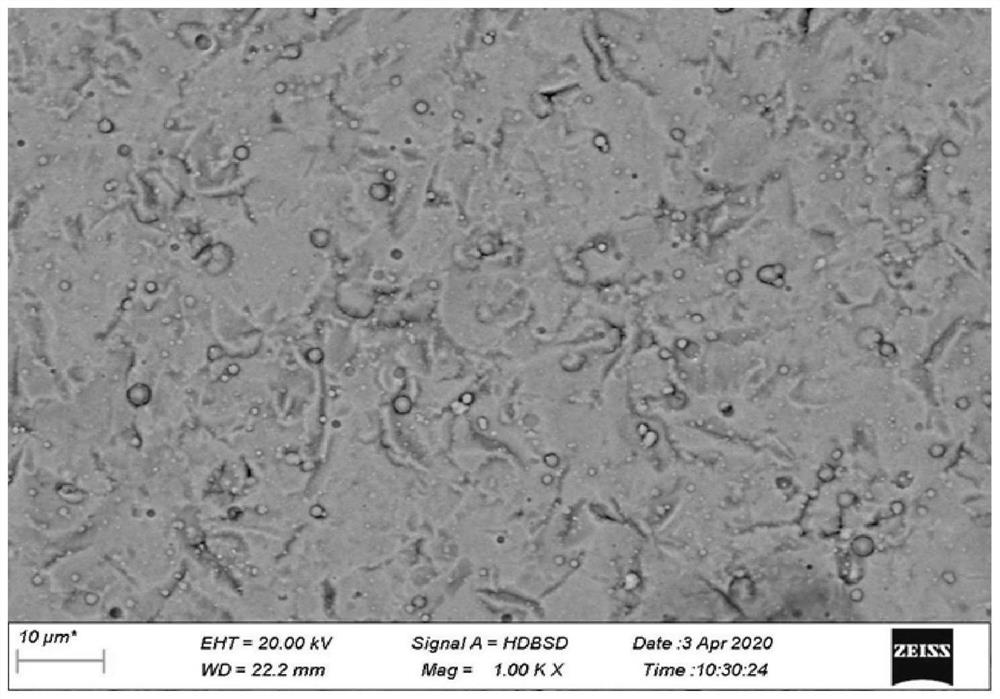

Image

Examples

Embodiment 1

[0028] Micron-level pure iron powder and siloxane electromagnetic shielding composite material and preparation process, the micron-level pure iron powder, diameter of 30μm, mass of 500g, liquid siloxane 2.5g, first dissolve liquid siloxane in 20g of anhydrous Then add the liquid siloxane dissolved in absolute ethanol into the micron-sized pure iron powder for ball milling. The micron-level pure iron powder coated with siloxane is pressed into a number of circular sheets with a diameter of 20 mm and a thickness of 2 mm by a cold press, and the pressure is 100 MPa. -3 Pa, the sintering temperature is 1000°C, and after sintering, it is rolled to an electromagnetic shielding iron-based composite material sheet with a thickness of 0.3 mm.

Embodiment 2

[0030] Micron-scale, nano-scale pure iron powder and siloxane electromagnetic shielding composite material and preparation process, micron-scale pure iron powder, diameter of 10μm, mass of 300g, nano-scale pure iron powder, diameter of 500nm, mass of 300g, liquid state 10g of siloxane, first dissolve the liquid siloxane in 50g of anhydrous ethanol, then add the liquid siloxane dissolved in the anhydrous ethanol into the micron-sized and nano-sized pure iron powder for ball milling, the ball milling time is 60min, the ball milling After drying, the drying temperature is 120°C, and the drying time is 60 minutes. After drying, the micron-level and nano-level pure iron powder coated with siloxane on the surface is pressed by a cold press into a number of lengths, widths of 50mm, and heights of 25mm. The cuboid, the pressure is 150MPa, the cuboid is sintered at high temperature in a vacuum, and the vacuum degree is 10 -3 Pa, the sintering temperature is 1100°C, and after sintering,...

Embodiment 3

[0032] Nano-scale pure iron powder and siloxane electromagnetic shielding composite material and preparation process, nano-scale pure iron powder, diameter of 200nm, mass of 500g, liquid siloxane 20g, liquid siloxane is first dissolved in 120g of absolute ethanol Then add the liquid siloxane dissolved in absolute ethanol into the nano-scale pure iron powder for ball milling. The nano-scale pure iron powder coated with siloxane was pressed into several hollow cylinders with an inner diameter of 30mm, an outer diameter of 60mm, and a length of 100mm by cold isostatic pressing, and the pressure was 180MPa. High temperature sintering, vacuum degree is 10 -3 Pa, the sintering temperature is 1200°C, and after sintering, it is rolled to an electromagnetic shielding iron-based composite material pipe with a thickness of 1mm and an inner diameter of 10mm.

[0033] Effect evaluation 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap