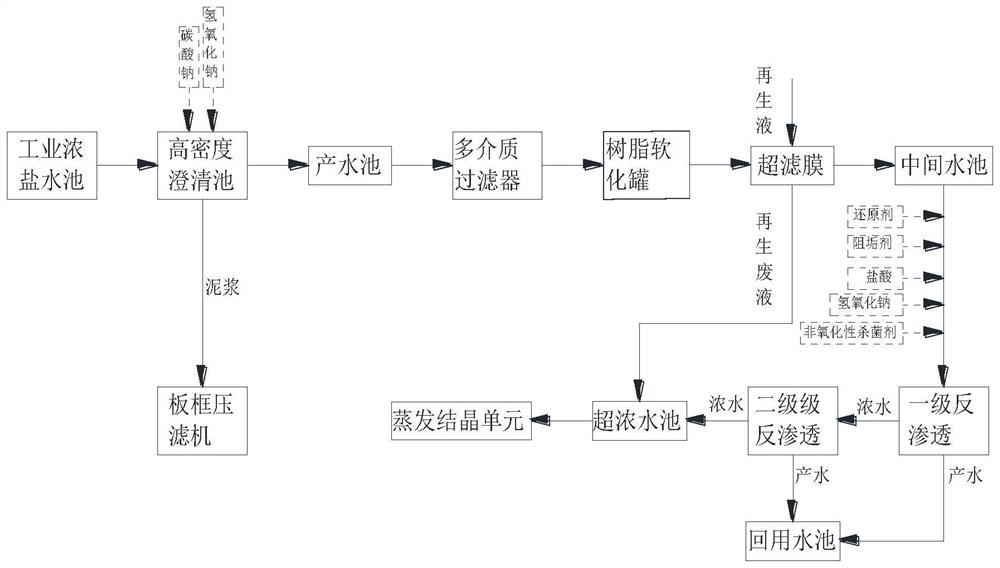

Industrial strong brine zero discharge treatment system and method

The technology of a treatment system and a treatment method, which is applied in the field of industrial concentrated brine zero discharge treatment system, can solve the problems of increasing the treatment capacity of an evaporative crystallization unit, high operation cost, and many treatment units, and achieves low operation cost, stable process, and treatment cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

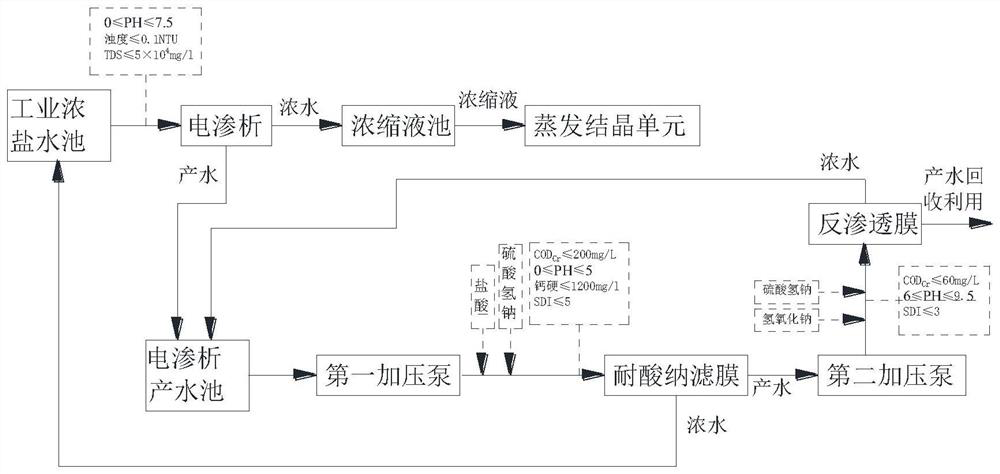

Method used

Image

Examples

Embodiment 1

[0045] Iron and steel plant water treatment station, the amount of industrial brine to be treated is 730m 3 / h, the processing method used is the processing method of the present invention, and the concrete processing steps are as follows:

[0046] (1) The industrial concentrated brine is stored in the industrial brine tank, and is transported to electrodialysis by water pump for treatment. The electrodialysis uses direct current as the driving force for desalination and L concentration, and the organic matter and salt are separated through the ion exchange membrane, and the electrodialysis concentrate is carried out. It is stored in the concentrated liquid pool, and then enters the evaporator crystallization unit for thorough treatment. The electrodialysis water enters the electrodialysis water tank, and then enters the acid-resistant nanofiltration membrane through the pressurized pump. The acid-resistant nanofiltration membrane concentrated water is returned to the industr...

Embodiment 2

[0066] Iron and steel plant water treatment station, the amount of industrial brine to be treated is 60m 3 / h, the processing method used is the processing method of the present invention, and the concrete processing steps are as follows:

[0067] (1) The industrial concentrated brine is stored in the industrial concentrated brine tank, and is transported to electrodialysis by a water pump for treatment. The electrodialysis uses direct current as the driving force for desalination and L concentration, and the organic matter and salt are separated through the ion exchange membrane, and the electrodialysis concentrate is carried out. It is stored in the concentrated liquid pool, and then enters the evaporator crystallization unit for thorough treatment. The electrodialysis water enters the electrodialysis water tank, and then enters the acid-resistant nanofiltration membrane through the pressurized pump. The acid-resistant nanofiltration membrane concentrated water is returned ...

Embodiment 3

[0075] Iron and steel plant water treatment station, the amount of industrial brine to be treated is 20m 3 / h, the processing method used is the processing method of the present invention, and the concrete processing steps are as follows:

[0076] (1) The industrial concentrated brine is stored in the industrial concentrated brine tank, and is transported to electrodialysis by a water pump for treatment. The electrodialysis uses direct current as the driving force for desalination and L concentration, and the organic matter and salt are separated through the ion exchange membrane, and the electrodialysis concentrate is carried out. It is stored in the concentrated liquid pool, and then enters the evaporator crystallization unit for thorough treatment. The electrodialysis water enters the electrodialysis water tank, and then enters the acid-resistant nanofiltration membrane through the pressurized pump. The acid-resistant nanofiltration membrane concentrated water is returned ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com