Sodium ion composite polymer solid electrolyte and preparation method thereof

A composite polymer and solid-state electrolyte technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of restricting the promotion and application of flexible electronic devices, low load of electrode active materials, and volume changes of electrode materials. Improving ionic conductivity and electrochemical performance, high adhesion, and the effect of alleviating agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

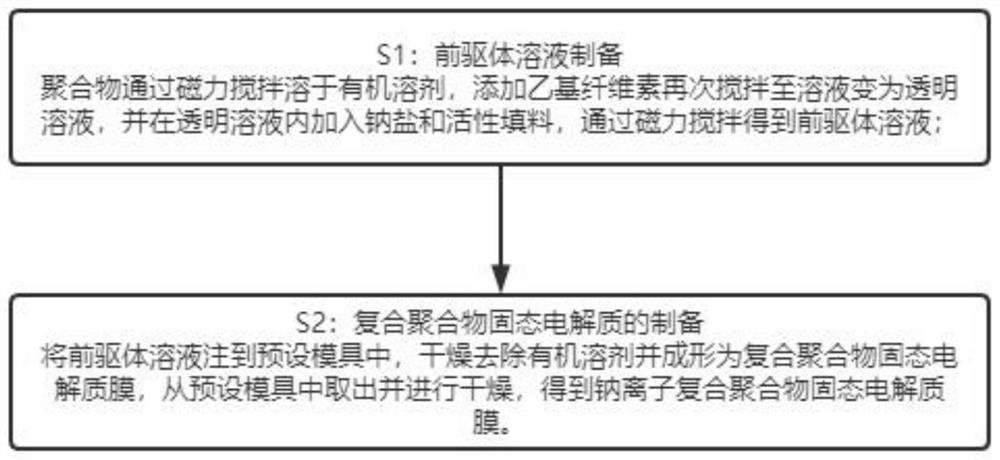

[0037] A preparation method of sodium ion composite polymer solid electrolyte, comprising the following steps:

[0038] S1: Precursor Solution Preparation

[0039] The polymer is dissolved in the organic solvent by magnetic stirring, and ethyl cellulose is added and stirred again until the solution becomes a transparent solution, and sodium salt and active filler are added into the transparent solution, and the precursor solution is obtained by magnetic stirring;

[0040] S2: Preparation of composite polymer solid electrolyte

[0041] The precursor solution is injected into a preset mold, dried to remove the organic solvent and formed into a composite polymer solid electrolyte membrane, taken out from the preset mold and dried to obtain a sodium ion composite polymer solid electrolyte membrane.

[0042]In the step of preparing the precursor solution, the preparation process adopts the preset sodium salt, the preset sodium electrolytic solution concentration and the first pres...

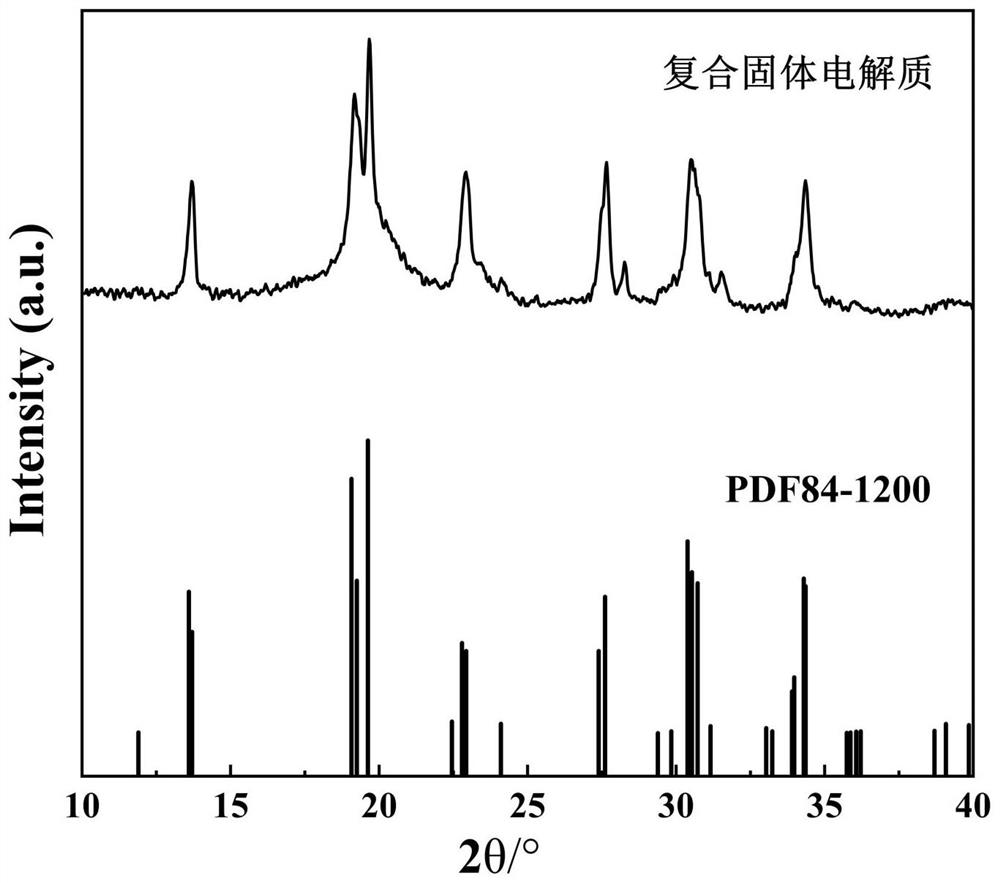

Embodiment 1

[0065] (1) Preparation of precursor solution: Weigh PEO in the proportion of 30wt.% and dissolve it in acetonitrile solution and stir, after complete dissolution, add 1wt.% ethyl cellulose and continue stirring until the solution is transparent, and then add 0.5wt.% NASICON active filler and 0.5vol.% sodium salt and continue to stir, the sodium salt is a mixed solution of sodium perchlorate, dimethyl carbonate and ethyl methyl carbonate, the concentration is 1mol / L, the stirring time is 24h, and the rotating speed is 800r / min; A homogeneous mixed solution of polymer, organic solvent, ethyl cellulose, sodium salt and active material completely solvent is obtained.

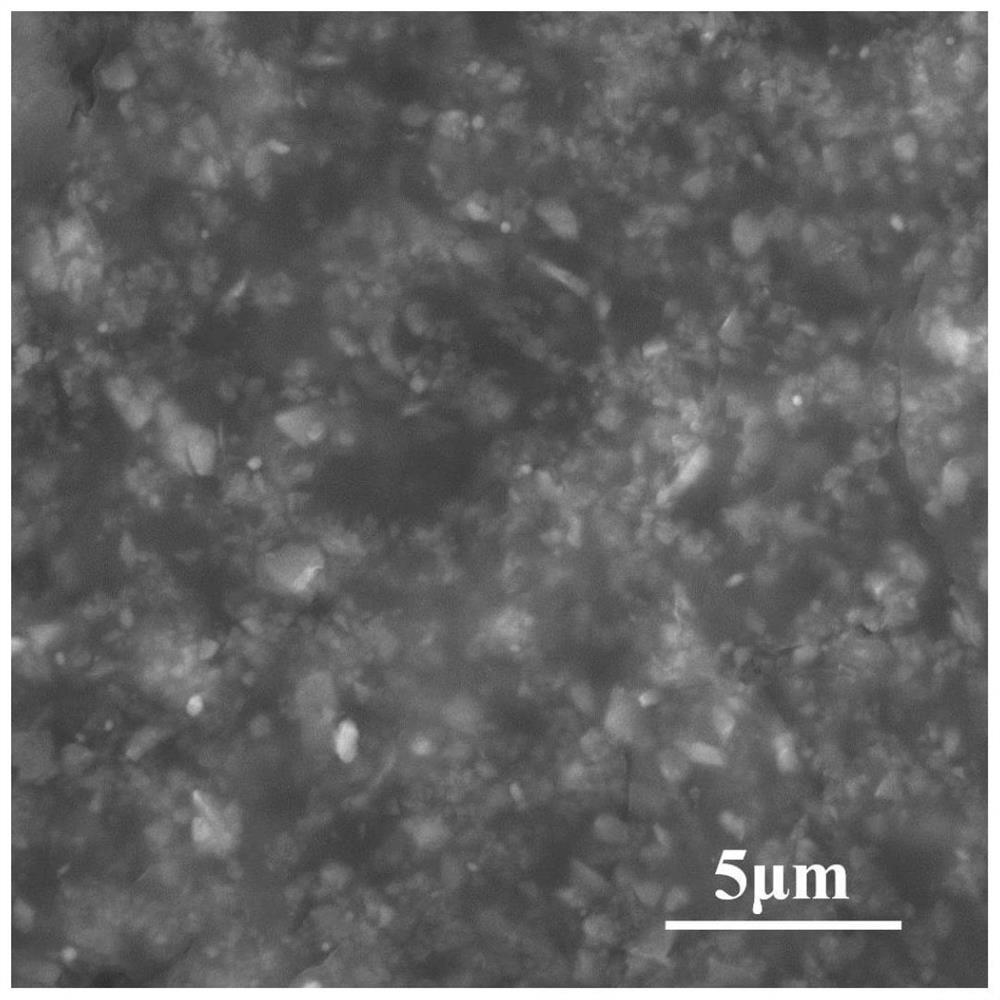

[0066] (2) Preparation of composite polymer solid electrolyte: the mixed solution obtained in step (1) is slowly poured into a polytetrafluoroethylene mold, and placed in a vacuum drying box with a temperature of 80 ° C for 24 hours to remove the above-mentioned organic solvent, A composite solid-state electrolyte m...

Embodiment 2

[0069] (1) Preparation of precursor solution: Weigh PEO in the proportion of 40wt.% and dissolve it in acetonitrile solution and stir, after complete dissolution, add 10wt.% ethyl cellulose and continue stirring until the solution is transparent, then add 40wt.% NASICON active filler and 10vol.% sodium salt and continue to stir, the sodium salt is a mixed solution of sodium perchlorate, dimethyl carbonate and ethyl methyl carbonate, the concentration is 0.8mol / L, the stirring time is 12h, and the rotating speed is 1000r / min; A homogeneous mixed solution of polymer, organic solvent, ethyl cellulose, sodium salt and active material in complete solvent.

[0070] (2) Preparation of composite polymer solid electrolyte: the mixed solution obtained in step (1) is slowly poured into a polytetrafluoroethylene mold, and placed in a vacuum drying box with a temperature of 100 ° C for 12 hours to remove the above-mentioned organic solvent, A composite solid-state electrolyte membrane was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com