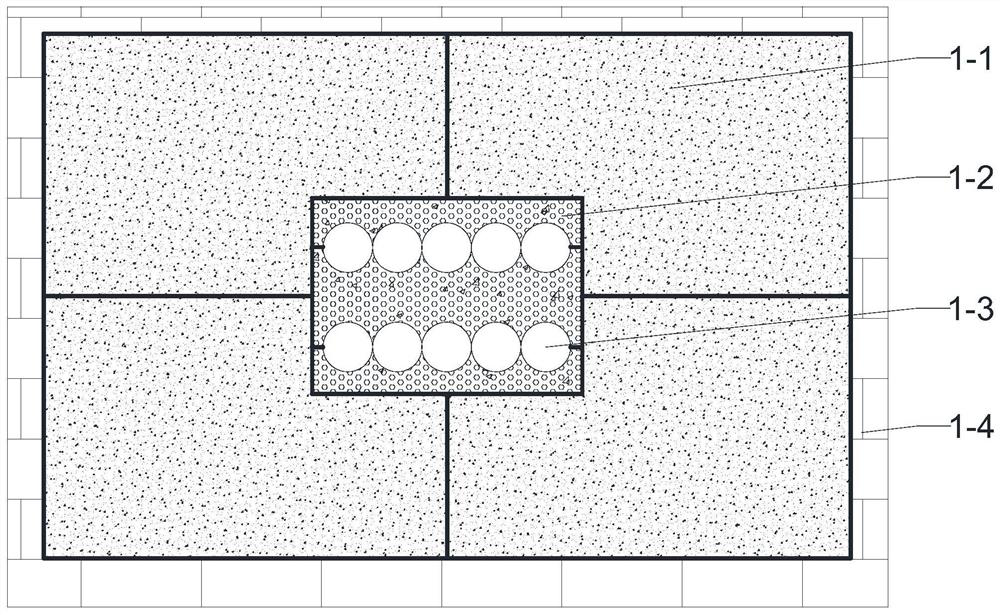

Cable channel composite material laminated plate fireproof partition and construction method thereof

A composite material layer and cable channel technology, applied in the direction of chemical instruments and methods, artificial islands, layered products, etc., can solve the problems of unable to prevent the spread of fire, rapid decline in structural performance, poor fire performance, etc., to achieve good molding Performance, high degree of sealing, good fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

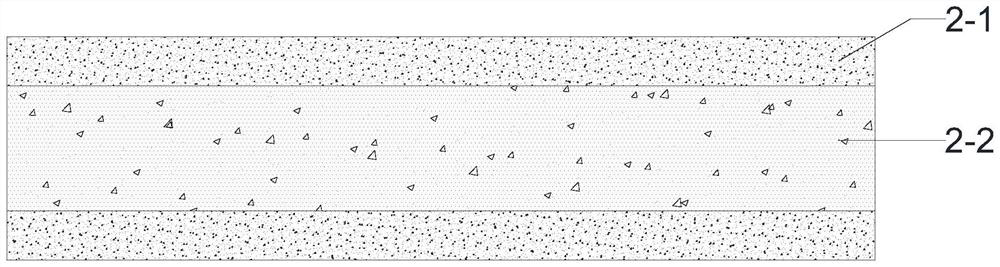

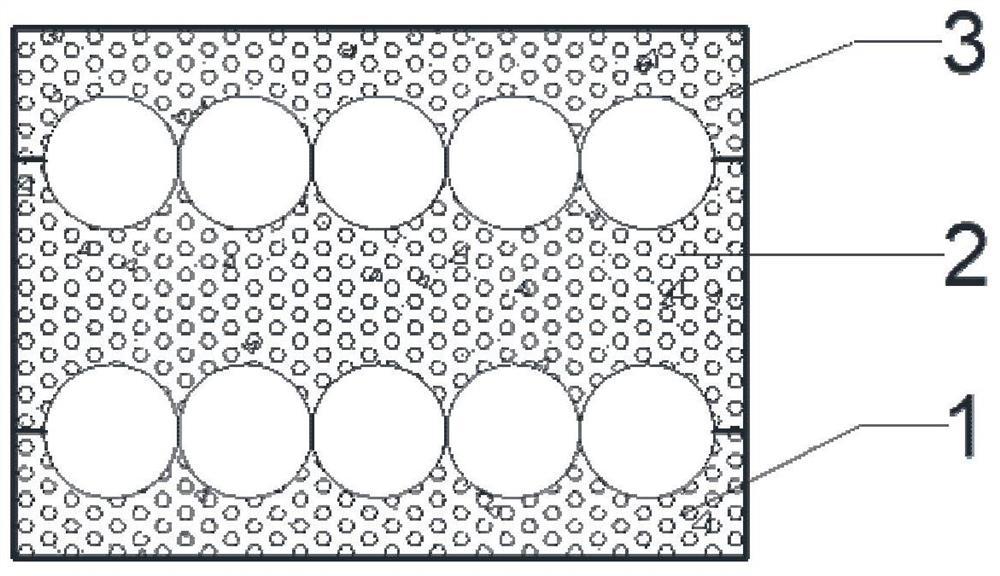

Method used

Image

Examples

Embodiment 1

[0042] The magnesium phosphate gel suspension is composed of dead-burned magnesium oxide powder, potassium dihydrogen phosphate, calcined vermiculite powder, fly ash and borax retarder; the mass ratio of magnesium oxide powder and potassium dihydrogen phosphate is 3:1, and the calcined Vermiculite powder and fly ash accounted for 10% of the total gel, respectively, and borax retarder accounted for 6% of the magnesium oxide powder. The magnesium phosphate gel is mixed with water according to the stated proportion to form a magnesium phosphate cementitious slurry, which is cured to form a magnesium phosphate cementitious material; the thickness of the magnesium phosphate adhesive layer between the silica aerogel sheet and the heat-resistant foam concrete 0.5cm; the fireproof sealing material of the composite laminate and the cable are sealed with a fireproof caulking material; the fireproof caulking material in the fireproof sealing of the composite laminate is a mixture of magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com