Antibacterial flame-retardant polyethylene material and preparation method thereof, antibacterial flame-retardant polyethylene film and preparation method thereof

A flame retardant polyethylene and polyethylene technology is applied in the field of antibacterial flame retardant polyethylene film and its preparation, and can solve the problems of inability to meet application requirements and poor performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

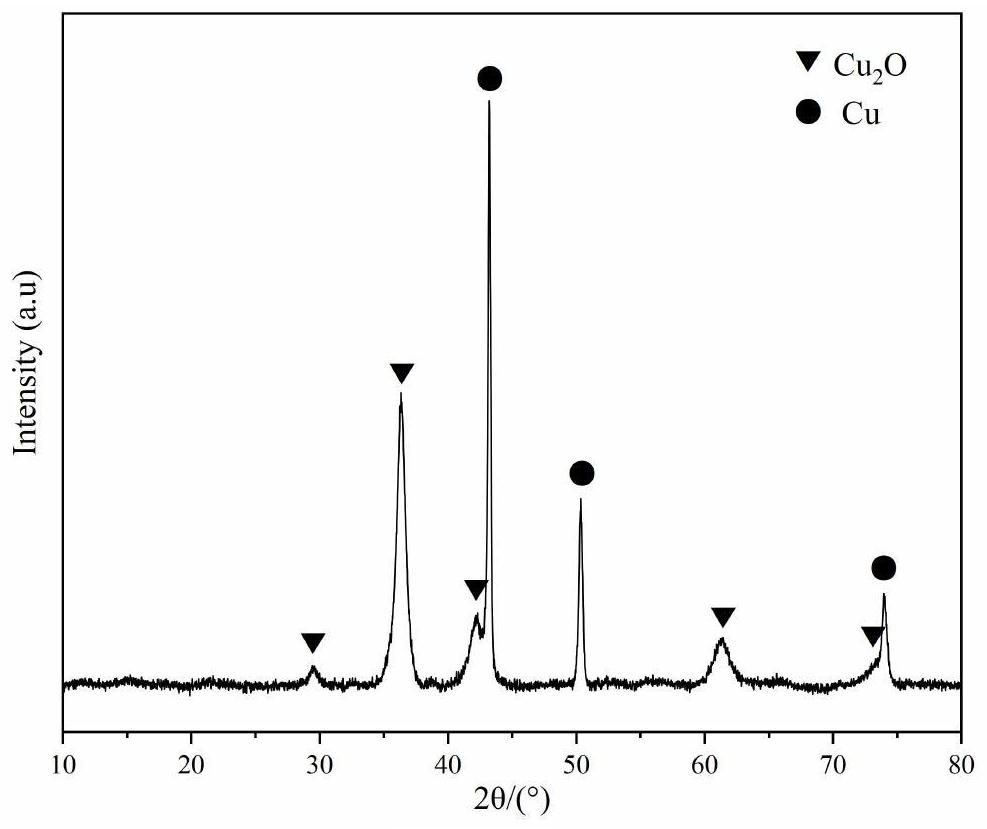

[0035] In the present invention, the preparation method of the nano-copper oxide-polymer composite material preferably includes the following steps:

[0036] Mixing organic copper salt, polymer material carrier and organic solvent to obtain a mixture precursor;

[0037] removing the organic solvent from the mixture precursor to obtain a dry mixture precursor;

[0038] The dried mixture precursor is calcined to obtain the nano-copper oxide-polymer composite material.

[0039] In the present invention, the organic copper salt, the polymer material carrier and the organic solvent are mixed to obtain the mixture precursor.

[0040] In the present invention, the organic copper salt is preferably copper formate.

[0041] In the present invention, the organic solvent is preferably ethanol.

[0042] In the present invention, the polymer material carrier is preferably one or more of polytetrafluoroethylene, nylon 66, polyvinyl chloride, polycarbonate and polyphenylene sulfide.

[0...

Embodiment 1

[0101] Step 1: fully mix copper (II) formate, polymer material carrier (polyvinyl chloride) and absolute ethanol through magnetic stirring to obtain a mixture precursor; remove the ethanol solvent in the mixture precursor through a blast drying oven , to obtain a dried mixture precursor; the dried mixture precursor is calcined at 275 ° C to obtain the copper oxide-polymer composite material, and the mass ratio of the nano-copper oxide to the polymer carrier is 1: 6.

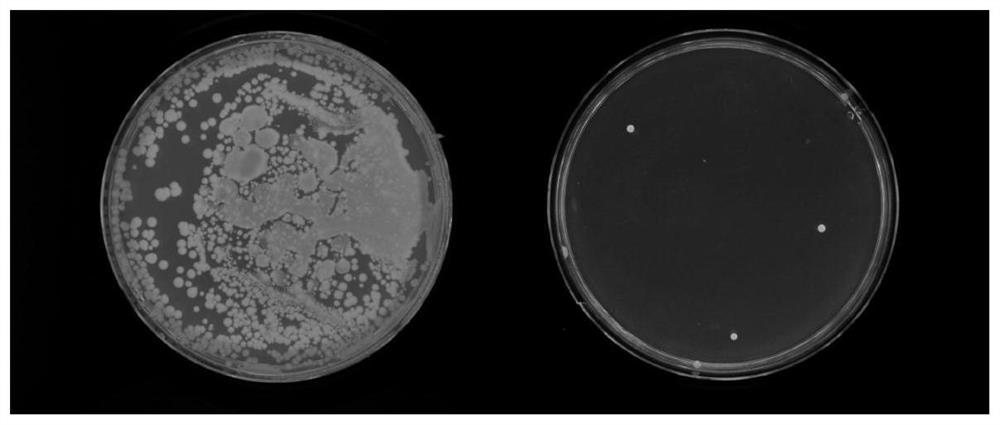

[0102] The low-density polyethylene, copper oxide-polymer composite material, zinc stannate, nano-calcium carbonate, antioxidant, and coupling agent are mixed according to a certain dose and uniformly mixed by a high-speed mixer, and then passed through a twin-screw After mixing, melting, cooling, pelletizing and drying in the compounding extruder, the masterbatch of antibacterial and flame retardant polyethylene is obtained.

[0103] Among them, the mass percentages of low density polyethylene, copper oxide-pol...

Embodiment 2

[0108] Example 2 is basically the same as Example 1. Only in step 2, the antibacterial and flame-retardant polyethylene material prepared in step 1 is directly melted and extruded by an extrusion film blowing machine, and is no longer processed with low-density polyethylene. The process of mixing ethylene ingredients to obtain antibacterial flame retardant polyethylene film. In the obtained antibacterial and flame retardant polyethylene film material, the mass ratio of the antibacterial agent copper oxide-polymer composite material is 2.0 wt %, and the mass ratio of the flame retardant zinc stannate is 10.0 wt %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com