Preparation and application of Fenton promoter for continuous flow drug wastewater treatment

A co-catalyst and wastewater treatment technology, which is applied in the field of water treatment, can solve the problems of low wastewater treatment efficiency and difficulty in using nano-catalysts, and achieve the effects of promoting iron ion circulation, excellent structural strength, and avoiding easy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

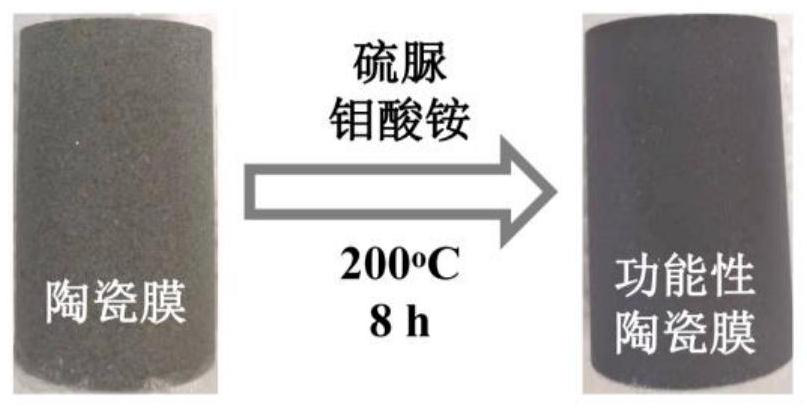

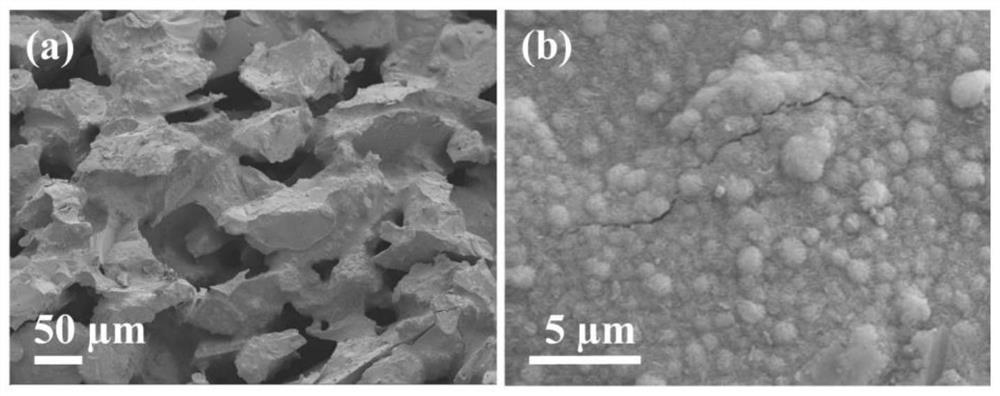

[0038]Prepare 25mL (0.05M) ammonium molybdate solution and 25mL (0.1M) thiourea solution, disperse and mix them uniformly by ultrasonic for 20min, and transfer them into a 100mL polytetrafluoroethylene reactor; use 100mL deionized water to wash the discarded The tubular ceramic membrane was dried in an oven at 60°C. The size of the tubular ceramic membrane was Φ3.0cm×2.0cm×5.0cm (outer diameter*inner diameter*height, hollow structure, membrane volume was 20mL), and the pore size was 30μm , the porosity is 43%, and then the dried tubular ceramic membrane is transferred to the above mixed reaction solution; finally, the polytetrafluoroethylene reaction kettle is sealed and placed in a 200 ℃ oven for hydrothermal reaction for 8 hours to obtain molybdenum sulfide. Modified Functional Ceramic Membranes (MoS x / CM) (eg figure 1 and figure 2 shown).

Embodiment 2

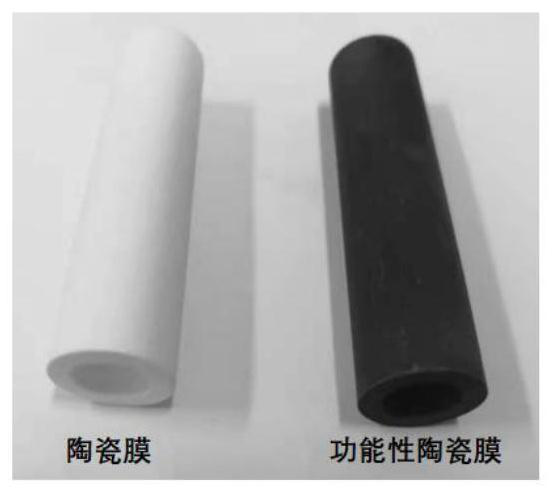

[0040] Prepare 12mL (0.2M) ammonium molybdate solution and 12mL (1.0M) thiourea solution, disperse uniformly and mix them by ultrasonic for 20min, transfer them into a 50mL polytetrafluoroethylene reactor; use 100mL deionized water to wash the discarded The tubular ceramic membrane was dried in an oven at 60°C. The size of the tubular ceramic membrane was Φ1.2cm×0.8cm×3.0cm, the pore size was 0.5μm, and the porosity was 28%. Then the dried tubular ceramic membrane was dried. Transfer to the above mixed reaction solution; finally, seal the polytetrafluoroethylene reaction kettle and place it in a 150 °C oven for hydrothermal reaction for 20 h, to obtain a functional ceramic membrane (MoS) modified with molybdenum sulfide. x / CM) (eg image 3 shown).

Embodiment 3

[0042] (1) One end of the functional ceramic membrane prepared in Example 1 was sealed as the bottom; then, it was used as a Fenton co-catalyst and placed in the reaction chamber of the continuous flow wastewater treatment reactor, and the diameter of the reaction chamber was 11.0 cm, The height is 5.0cm, and the plexiglass on the upper layer of the reaction chamber is provided with uniformly distributed holes that are consistent with the size of the functional ceramic membrane in Example 1, and the diameter of the holes is 3.0cm (such as Figure 4 );

[0043] (2) Taking 10 mg / L clothianidin wastewater (simulated pharmaceutical wastewater) as the treatment object, the concentration of iron ions in the wastewater is 0.04 mM, and the concentration of hydrogen peroxide is 0.4 mM, through the valve set in the continuous flow wastewater treatment reactor Conditioning wastewater in MoS x The residence time in the / CM channel was set to 8 min. After the reactor runs for 60 hours, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com