Synthesis method of cycloethane carbonate

A technology of cycloethane carbonate and a synthesis method, applied in the chemical industry, can solve the problems of high price, large amount of catalyst, long reaction time and the like, and achieve the effects of low price, high product yield and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

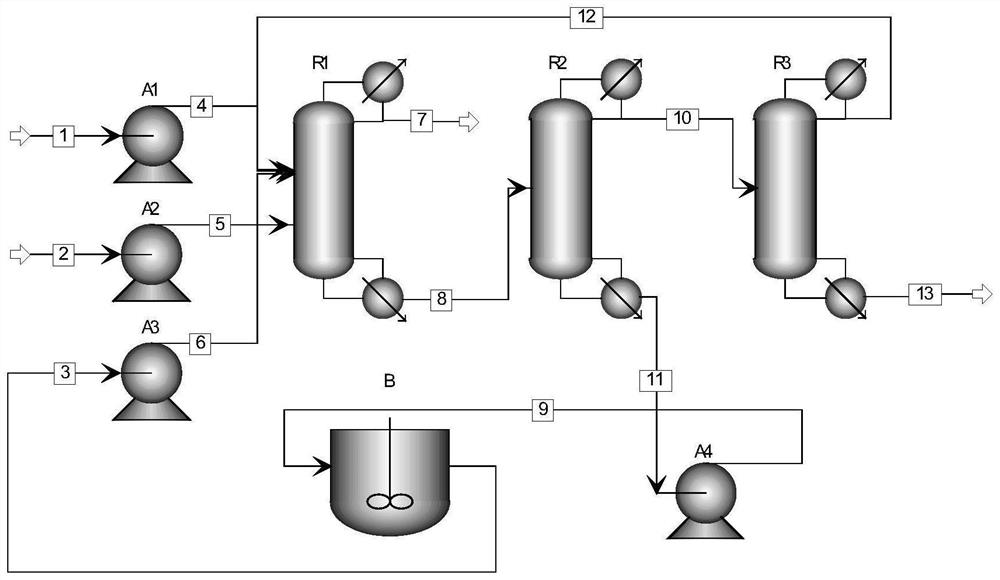

[0028] The invention provides a method for synthesizing cycloethane carbonate, and the process flow refers to figure 1 , the method specifically includes the following steps:

[0029] (1) catalyst preparation: the alkali metal alkoxide is dissolved in raw material ethylene glycol or methanol to prepare a catalyst material;

[0030] (2) transesterification reaction: the ethylene glycol material 1 enters the reactive distillation column R1 through the ethylene glycol delivery pump A1 and the ethylene glycol delivery pump outlet pipeline 4, and the dimethyl carbonate material 2 passes through the dimethyl carbonate The delivery pump A2 and the dimethyl carbonate delivery pump outlet pipeline 5 enter the reactive distillation column R1, and the catalyst material passes through the catalyst configuration device outlet pipeline 3, the catalyst and ethylene glycol mixed solution delivery pump A3 and the catalyst delivery pump outlet pipeline 6 enter the reactive distillation column ...

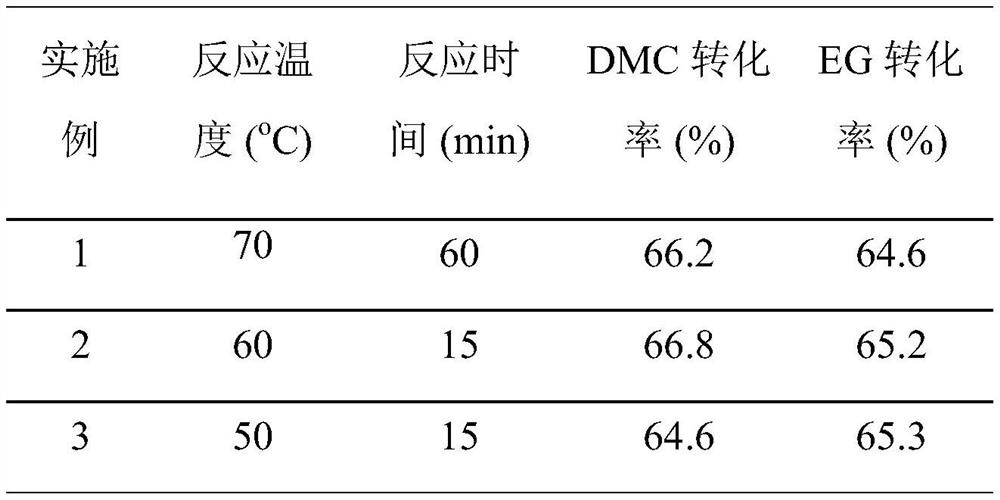

Embodiment 1

[0036] use figure 1 As shown in the synthetic process of cycloethane carbonate, 10g of ethylene glycol and 14.5g of dimethyl carbonate were weighed to form a raw material solution, mixed evenly, and then added to the bottom of the reactive distillation column, raised to 70°C, and then added with 113mg of methanol Potassium began to react for 60 minutes after the reaction, and the liquid phase material was taken for qualitative and quantitative analysis by gas chromatography. The conversion rates of DMC and EG were 66.2% and 64.6%, and the selectivity of EC and ME were 92.2% and 99.8%, respectively.

Embodiment 2

[0038] use figure 1 As shown in the synthetic process of cycloethane carbonate, 10g of ethylene glycol and 14.5g of dimethyl carbonate were weighed to form a raw material solution, mixed evenly, and then added to the bottom of the reactive distillation column, raised to 60°C, and then added with 113mg of methanol Potassium began to react for 15 minutes after the reaction, and the liquid phase material was taken for qualitative and quantitative analysis by gas chromatography. The conversion rates of DMC and EG were 66.8% and 65.2%, and the selectivities of EC and ME were 92.3% and 99.8%, respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com