Waterborne alkyd resin composite material as well as preparation method and application thereof

A technology of water-based alkyd resin and composite materials, which is applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., which can solve the problems of unsatisfactory outdoor coating, slow surface drying of coatings, and poor water resistance, and achieve improvement Effects of initial water resistance, surface-drying speed improvement, and roughness enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

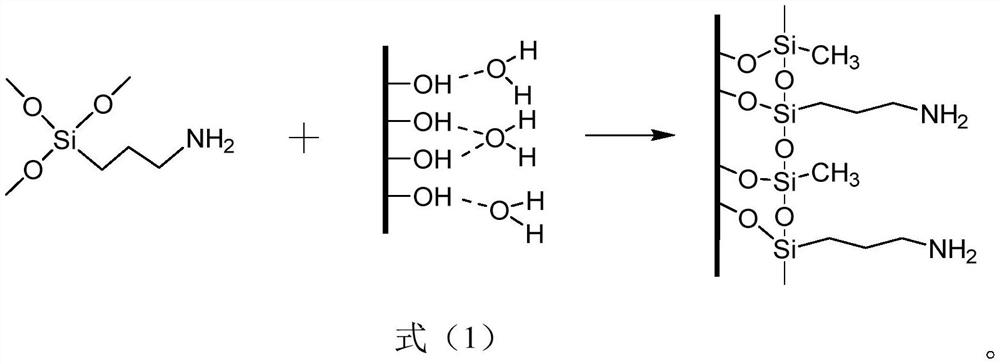

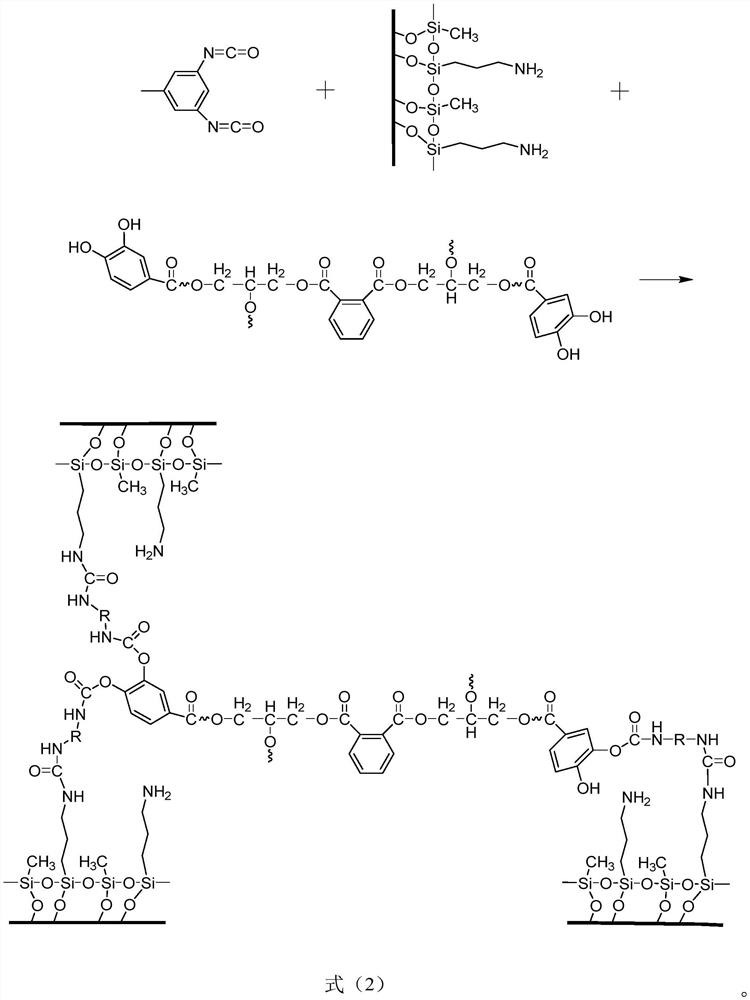

[0027] The preparation method of the water-based alkyd resin composite material provided by the present invention comprises the following steps:

[0028] S1, under protective atmosphere, mix vegetable oleic acid, polybasic acid, polyol, esterification catalyst and organic solvent, and carry out esterification reaction, obtain esterification product;

[0029] S2, the esterification product is reacted with a semi-end-capping agent to obtain a semi-end-capping esterification product, wherein the semi-end-capping agent is selected from at least one of o-hydroxybenzoic acid and o-hydroxynaphthoic acid;

[0030] S3, remove the solvent in the half-terminated esterification product, and then react with acid anhydride to obtain an acid value of 35 mgKOH·g -1 -55mgKOH g -1 The end-capped esterification product;

[0031] S4, diluting the end-capped esterification product, and then reacting with a neutralizing agent to obtain an alkyd resin polyol prepolymer; and

[0032] S5, after mix...

Embodiment 1

[0074] 57g of linoleic acid, 171g of soybean oleic acid, 128g of phthalic anhydride, 25.6g of isophthalic acid, 80g of trimethylolpropane, 60g of glycerol, 3g of antimony trioxide and 40g of xylene was heated to 140°C under nitrogen protection. After melting, the stirring was started, and the temperature was raised to 180°C. 35g of xylene was used as a reflux solvent, and the reaction was kept for 1 hour to remove the water generated by esterification and 18g of xylene. After toluene, the temperature was raised to 230°C at a rate of 0.5°C / min, and the reaction was maintained until the acid value of the system was 20 mgKOH·g. -1 At this time, the xylene was distilled off to obtain the esterified product.

[0075] Add 30g of 3,4-dihydroxybenzoic acid to the esterified product, and react at 210℃ until the acid value of the system is 12mgKOH·g -1 , to obtain a semi-terminated esterification product.

[0076] After the solvent in the semi-capped esterification product was evapora...

Embodiment 2

[0080] 90g of dehydrated ricinoleic acid, 115g of linoleic acid, 121g of phthalic anhydride, 24g of terephthalic acid, 75g of trimethylolpropane, 65g of glycerol, 3g of antimony trioxide and 40g of xylene was heated to 140°C under nitrogen protection. After melting, the stirring was started, and the temperature was raised to 180°C. 35g of xylene was used as a reflux solvent, and the reaction was kept for 1 hour to remove the water generated by esterification and 18g of xylene. After toluene, the temperature was raised to 230°C at a rate of 0.5°C / min, and the reaction was maintained until the acid value of the system was 20 mgKOH·g. -1 At this time, the xylene was distilled off to obtain the esterified product.

[0081] 35g of 2,3-dihydroxynaphthoic acid was added to the esterified product, and the reaction was carried out at 210°C until the acid value of the system was 12.5mgKOH·g -1 , to obtain a semi-terminated esterification product.

[0082] After the solvent in the semi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com