Modified polystyrene foam material and recycling method thereof

A technology of polystyrene foaming and styrene, which is applied in the field of plastic materials, can solve the problems of fragility, poor bonding performance, and low tensile strength, so as to increase the number of cycles, good recycling, and improve hydrophobicity and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

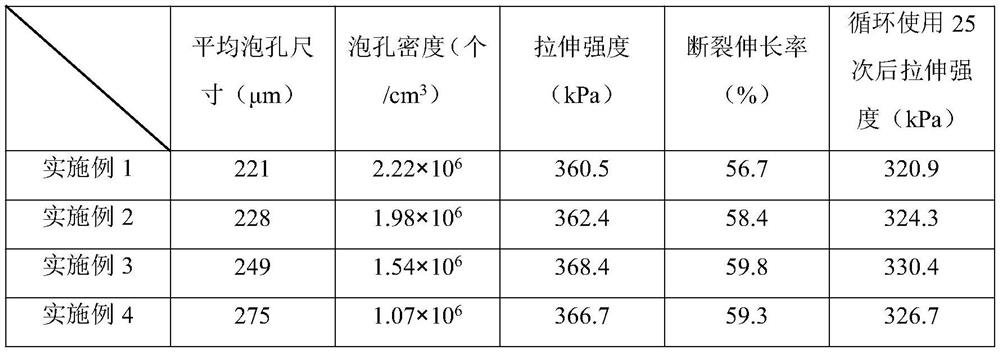

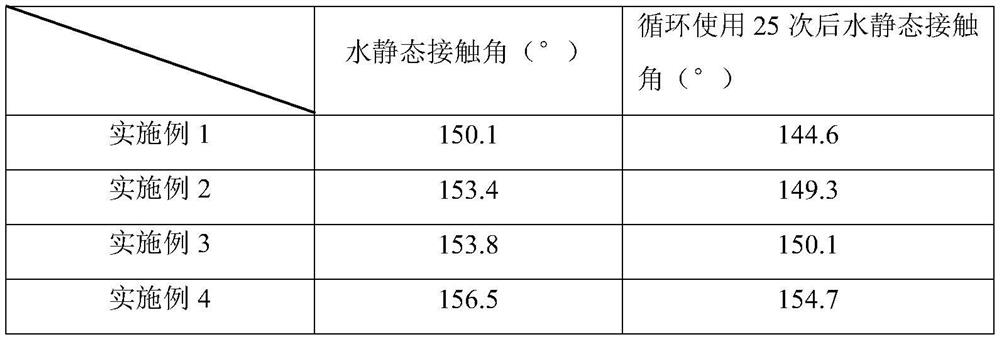

Examples

Embodiment 1

[0047] A preparation method of modified polystyrene foam material, in parts by weight, comprising the following steps:

[0048] Step 1: Dissolve 15 parts of styrene in 50 parts of ethanol to obtain a styrene solution;

[0049] Step 2: prepare 15 parts of ethylenediamine aqueous solution containing 0.25wt% sodium glycocholate, add styrene solution, and mix evenly, wherein the concentration of the ethylenediamine aqueous solution is 2.5mol / L;

[0050] Step 3: Siloxane phosphate was added dropwise at a temperature of 45°C and a stirring speed of 50rpm until a microemulsion was formed, then 2 parts of ethyl orthosilicate were added dropwise, and stirring was continued for 18h;

[0051] Step 4: distillation under reduced pressure to remove water and ethanol;

[0052] Step 5: add 0.15 part of benzoyl peroxide, heat to 60°C and stir for 1 h;

[0053] Step 6: add 70 parts of water, 5 parts of polyvinyl alcohol, and 0.05 part of mono-substituted β-cyclodextrin derivative, adjust the ...

Embodiment 2

[0078] A preparation method of a modified polystyrene foam material, in parts by weight, comprising the following steps:

[0079] Step 1: Dissolve 15 parts of styrene in 60 parts of ethanol to obtain a styrene solution;

[0080] Step 2: prepare 18 parts of ethylenediamine aqueous solution containing 0.25wt% sodium glycocholate, add styrene solution, and mix evenly, wherein the concentration of the ethylenediamine aqueous solution is 2.5mol / L;

[0081] Step 3: Add siloxane phosphate dropwise at a temperature of 48°C and a stirring speed of 60rpm until a microemulsion is formed, then dropwise add 3 parts of ethyl orthosilicate, and continue stirring for 18h;

[0082] Step 4: distillation under reduced pressure to remove water and ethanol;

[0083] Step 5: Add 0.16 part of benzoyl peroxide, heat to 65°C and stir for 1.5h;

[0084] Step 6: add 80 parts of water, 6 parts of polyvinyl alcohol, and 0.06 part of mono-substituted β-cyclodextrin derivative, adjust the stirring speed t...

Embodiment 3

[0109] A preparation method of a modified polystyrene foam material, in parts by weight, comprising the following steps:

[0110] Step 1: Dissolve 15 parts of styrene in 60 parts of ethanol to obtain a styrene solution;

[0111] Step 2: prepare 18 parts of ethylenediamine aqueous solution containing 0.25wt% sodium glycocholate, add styrene solution, and mix evenly, wherein the concentration of the ethylenediamine aqueous solution is 2.5mol / L;

[0112] Step 3: Add siloxane phosphate dropwise at a temperature of 48°C and a stirring speed of 70rpm until a microemulsion is formed, then dropwise add 3 parts of ethyl orthosilicate, and continue stirring for 18h;

[0113] Step 4: distillation under reduced pressure to remove water and ethanol;

[0114] Step 5: Add 0.16 part of benzoyl peroxide, heat to 65°C and stir for 1.5h;

[0115] Step 6: add 85 parts of water, 6 parts of polyvinyl alcohol, and 0.06 parts of mono-substituted β-cyclodextrin derivatives, adjust the stirring speed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com