Coated asphalt and preparation method and device thereof

A technology for preparing device and asphalt, which is applied in the processing of tar pitch/petroleum pitch/natural pitch, melting and processing tar pitch/petroleum pitch/natural pitch, and processing tar pitch/petroleum pitch/natural pitch by distillation, etc. Accurate processing, single product structure, poor product performance and other problems, to alleviate the pressure of resource economy and environment, low QI content, and accurate processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

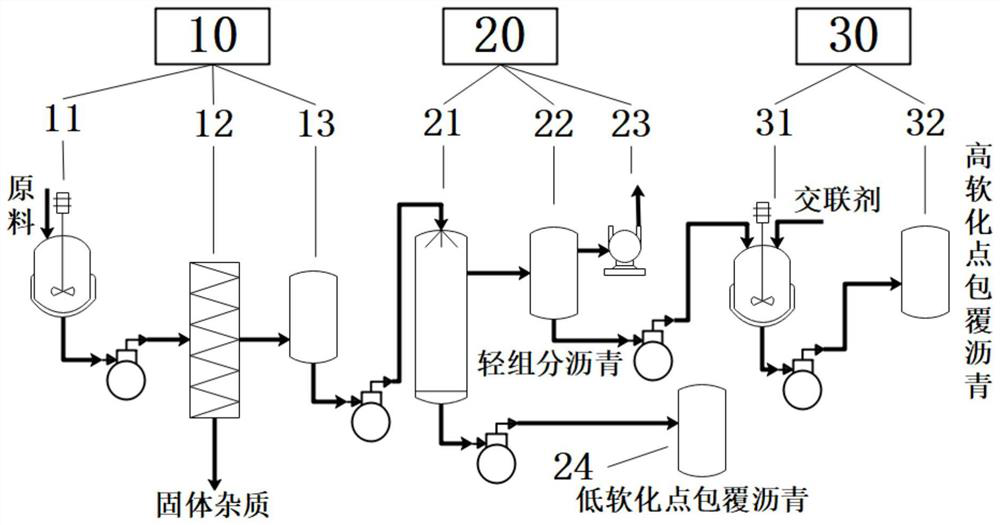

[0026] A first aspect of the present invention provides a method for preparing coated asphalt, comprising the following steps:

[0027] (1) after the coal liquefaction pitch is melted, it is filtered through a microfiltration membrane to obtain a refined pitch;

[0028] (2) molecular distillation is carried out with described refined pitch under vacuum condition, obtains light component pitch and low softening point coated pitch;

[0029] (3) Crosslinking the light component asphalt with a crosslinking agent to obtain a high softening point coated asphalt.

[0030] The pitch produced by coal liquefaction contains unreacted coal and inorganic impurities such as catalysts and metals. Therefore, in the present invention, the solid impurities in the asphalt need to be removed first. The use of microfiltration membrane filtration can remove unreacted coal and inorganic impurities such as catalysts and metals in the coal liquefaction asphalt raw material, so as to achieve the purp...

Embodiment l

[0073] The coal liquefaction pitch is heated to 280°C at a heating rate of 3°C / min in the raw material pitch heating and melting device 11, and is stirred at 280°C for 4 hours, and the microfiltration membrane is filtered through the microfiltration membrane filtration device 12, wherein the microfiltration The membrane pore size is 0.025 μm, the operating pressure is 0.2 MPa, and the temperature is 280 °C. The filter residue is solid impurities and primary QI, which are removed because they cannot pass through the filter membrane; the filtrate is the refined asphalt, which is collected in the refined asphalt collecting device 13 .

[0074] The refined asphalt in the refined asphalt collection device 13 is sent to the molecular distillation device 21 for distillation and cutting, wherein the operating temperature is 350 ° C and the vacuum degree is 10Pa, and the obtained light component enters the light component asphalt collecting device 22, and the obtained The heavy compone...

Embodiment 2-8

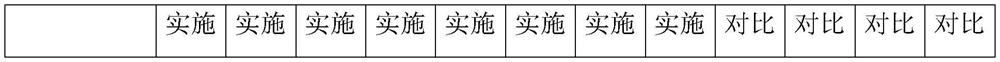

[0078] According to the method of Example 1, the difference is: the preparation parameter conditions are shown in Table 1, and the index of the finally obtained coated asphalt is shown in Table 2.

[0079] Table 1 Preparation parameters of coated asphalt

[0080]

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com