Flexible wire based on liquid metal and manufacturing method thereof

A liquid metal, flexible wire technology, applied in bendable conductors, manufacturing stretchable conductors/cables, conductors, etc., can solve the problems of low preparation efficiency, influence of electrical conductivity, complicated operation, etc., and achieve simple preparation methods and guaranteed The effect of electrical conductivity and wettability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

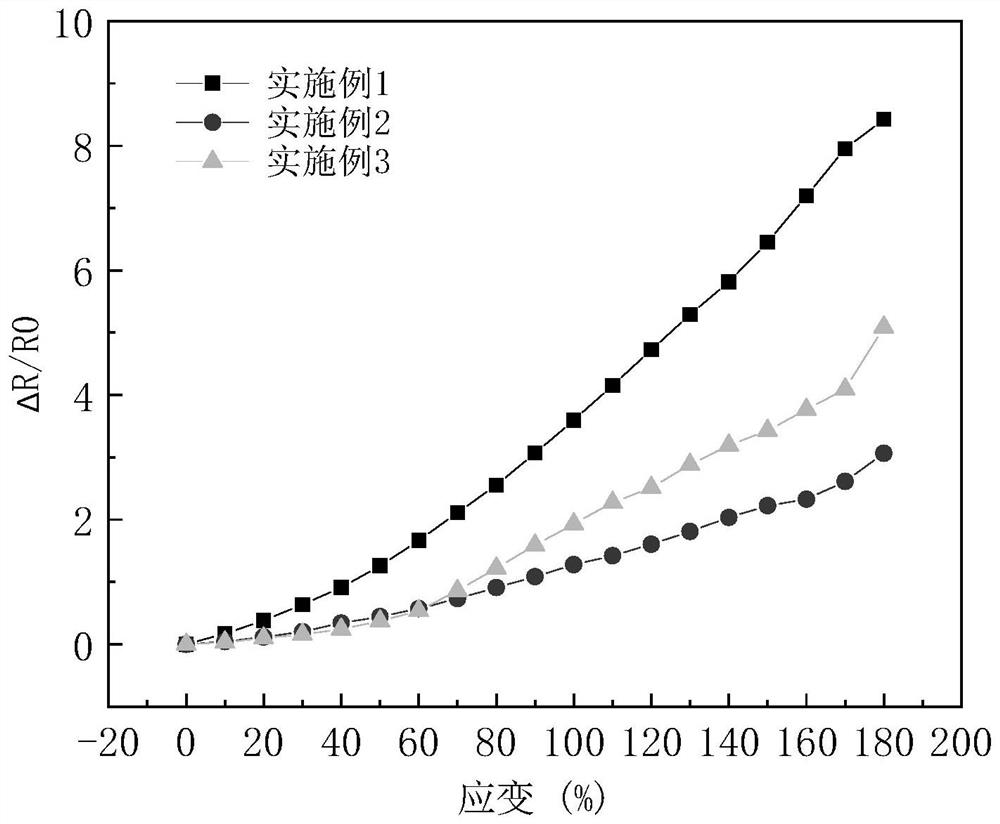

Embodiment 1

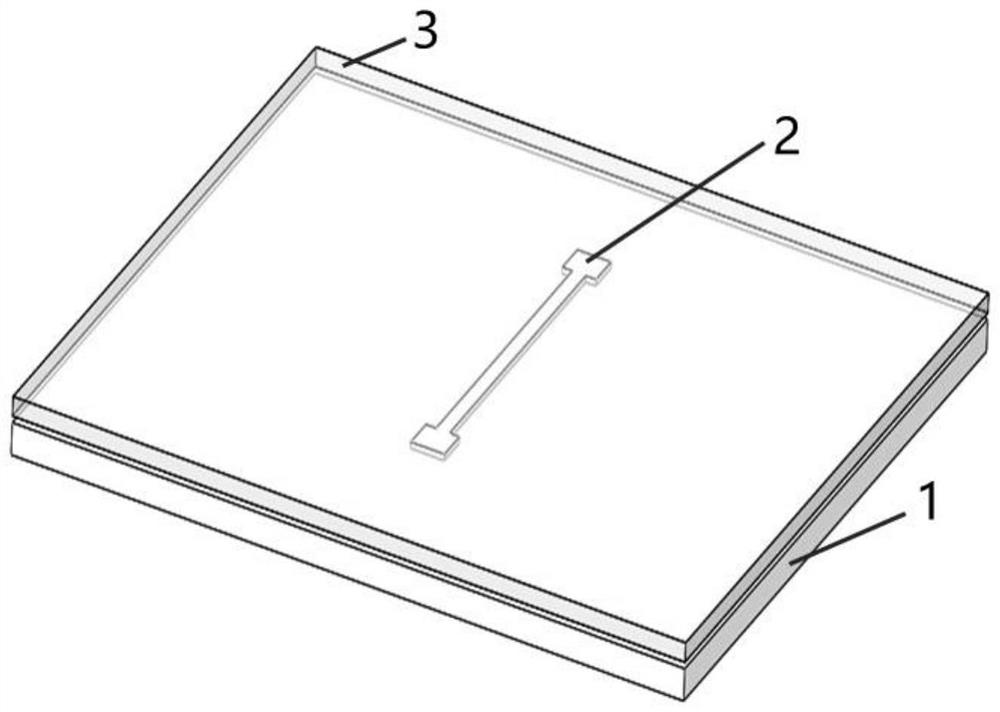

[0044] This embodiment provides a liquid metal-based flexible wire and a manufacturing method thereof. The flexible substrate 1 is a composite film of TPU and graphene oxide (GO), the liquid metal conductive pattern 2 is a prepared conductive path, and the encapsulation layer 3 is a TPU film prepared by electrostatic spraying.

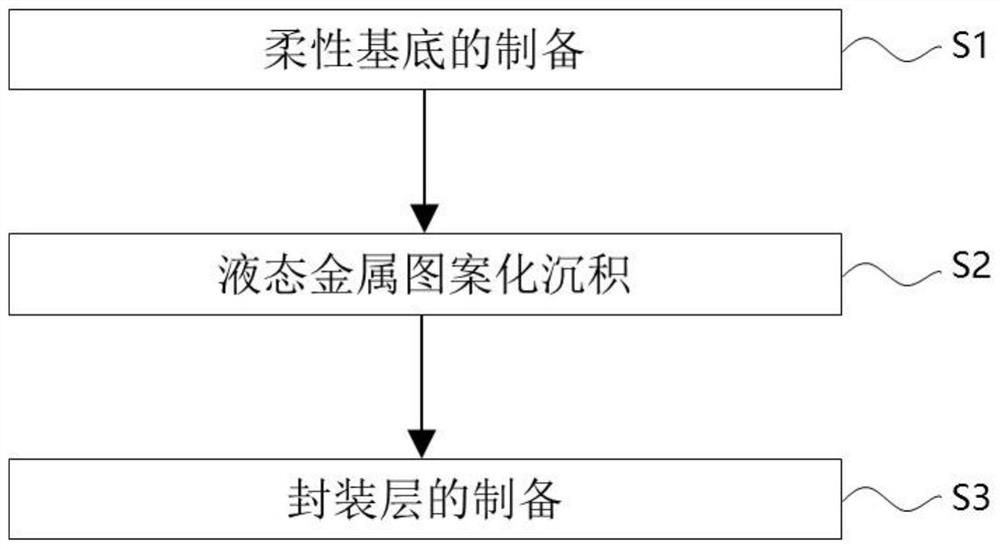

[0045] The manufacturing method of this embodiment comprises the following steps:

[0046] S1. First, the graphene oxide (GO) powder is dissolved in dimethylacetamide (DMAC) by ultrasonic, and the GO / TPU precursor mixed solution is obtained by magnetic stirring for 3h after adding TPU. The mass ratio is 0.5%, and the mass ratio of TPU to DMAC is 45%; then the precursor mixed solution is prepared by a spin coating process to obtain a film with a thickness of 200um, thereby completing the preparation of the flexible substrate 1 .

[0047] S2. The gallium-based liquid metal alloy and the Cu nano-powder are mixed together by magnetic stirring (the mass ra...

Embodiment 2

[0052] This embodiment provides a liquid metal-based flexible wire and a manufacturing method thereof. The flexible substrate is a TPU / GO nanofiber film, the liquid metal conductive pattern 2 is a prepared conductive path, and the encapsulation layer 3 is a TPU nanofiber film.

[0053] The manufacturing method of this embodiment comprises the following steps:

[0054] S1. First, the graphene oxide (GO) powder is dissolved in DMAC by ultrasonic, and the GO / TPU precursor mixed solution is obtained by magnetic stirring for 3 hours after adding TPU, wherein the mass ratio of GO and TPU is 0.5%, TPU The mass ratio of DMAC was 45%; the precursor solution was loaded into a syringe, and a GO / TPU nanofiber membrane was prepared by an electrospinning process (12kv, 300ul / h, 15cm).

[0055] S2. The gallium-based liquid metal alloy and the Cu nano-powder are mixed together by magnetic stirring (the mass ratio is 10%) to improve the conductivity and printability of the liquid metal conduc...

Embodiment 3

[0060] This embodiment provides a liquid metal-based flexible wire and a manufacturing method thereof. The flexible substrate 1 is a composite film of PDMS and polyvinyl alcohol resin (PVA), the liquid metal conductive pattern 2 is a prepared conductive path, and the encapsulation layer 3 is a PDMS film prepared by electrostatic spraying.

[0061] The manufacturing method of this embodiment comprises the following steps:

[0062] S1. First, mix the components A and B of the PDMS prepolymer at a ratio of 10:1 to obtain a PDMS solution, and prepare a PDMS film through a spin coating process; dissolve the TPU powder in DMAC (mass ratio is 45%), and stir magnetically for 3h Obtain the TPU solution; through the electrospinning process (12kv, 300ul / h, 15cm), the TPU solution is spray-printed on the above-mentioned PDMS film by the electrospinning process according to the preset trajectory, and finally the PVA solution is directly written on the above-mentioned patterned nanometer. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com