Microbial fuel cell using electron acceptor having high reduction potential and method for producing electrical energy using same

A technology of fuel cells and microorganisms, applied in biochemical fuel cells, fuel cells, battery electrodes, etc., to achieve the effects of increasing life, low reduction potential, and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

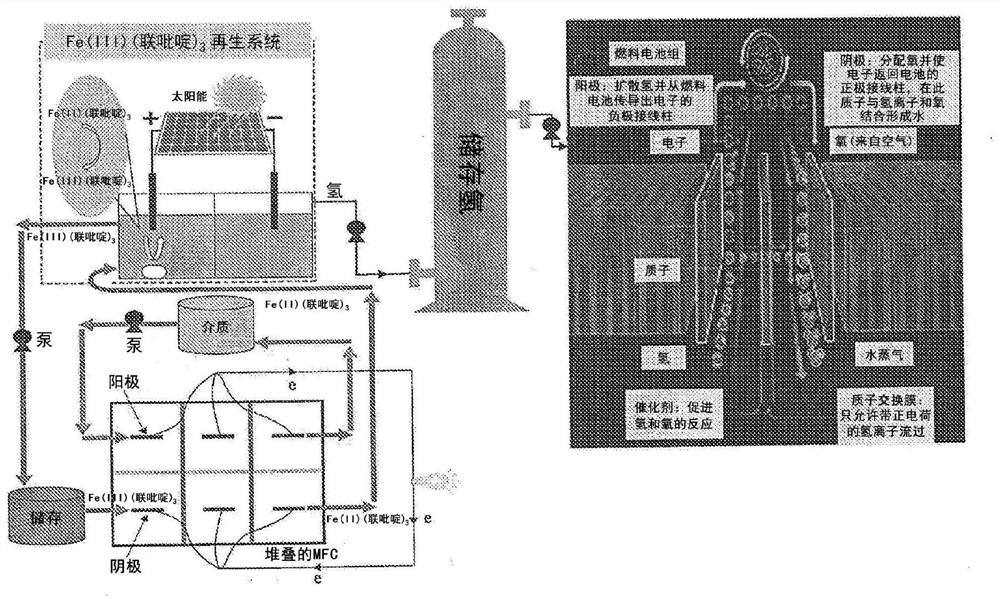

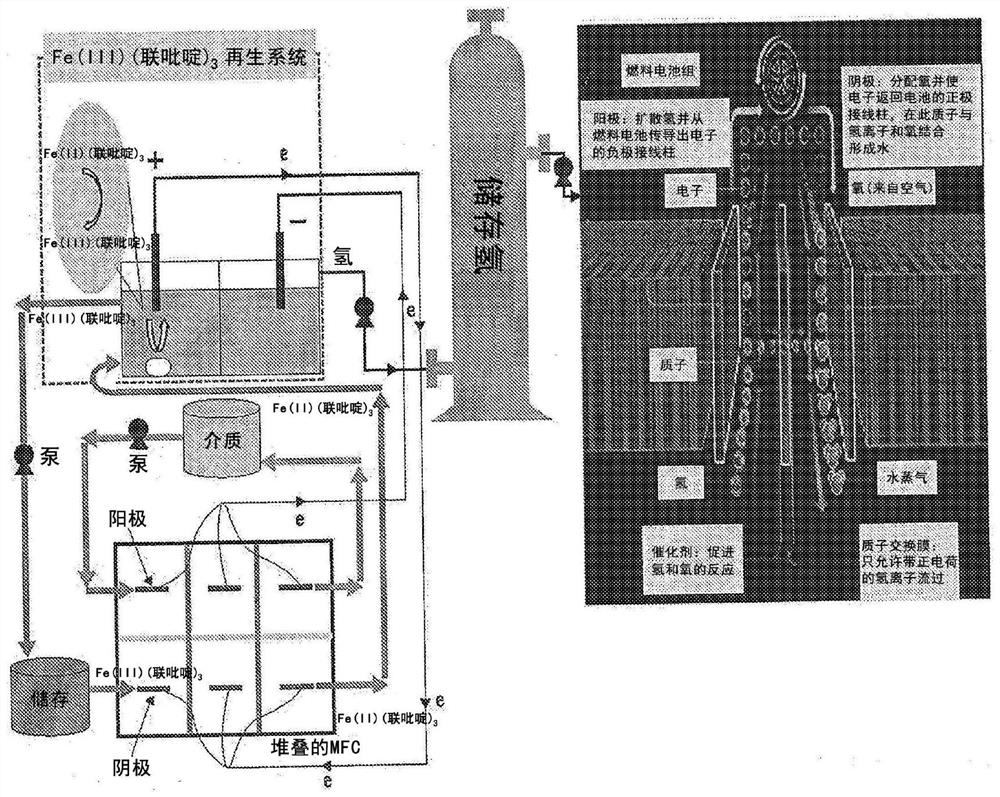

Method used

Image

Examples

Embodiment

[0068] Preparation of MFCs for polarization experiments and discharge experiments ( image 3 )

[0069] To investigate the effect of electron acceptors in MFC performance, a two-chamber microbial fuel cell design with an anode compartment with a working volume of 500 mL and a cathode compartment with a volume of 600 mL was used.

[0070] To test the electrodes, carbon brushes (D 4cm*L 7cm) or carbon felts (W 4cm*H 7cm) were used as anode materials. The carbon brushes used had a diameter of 4cm and a length of 7cm and provided an area of 28cm 2 . In addition, a graphite plate (2.5cm*6cm) or a carbon brush was used as the cathode.

[0071] An external circuit resistance of 1000Ω was connected between anode and cathode except during polarization experiments. The anode and cathode were separated with a pretreated ion exchange membrane (AEM, AMI-7001 or CEM, CEM-7001, Membrane International, USA (USA)).

[0072] Anaerobic inoculum was collected from anaerobic sludge previo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com