Wear-resistant round rod for agricultural machinery and production method of wear-resistant round rod

A production method and round bar technology, applied in the field of metallurgy, can solve the problems of changing agricultural machinery operating environment, affecting the normal operation of agricultural machinery, and the loss of agricultural machinery components, so as to increase wear resistance and practical performance, ensure surface quality, and eliminate center Shrinkage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

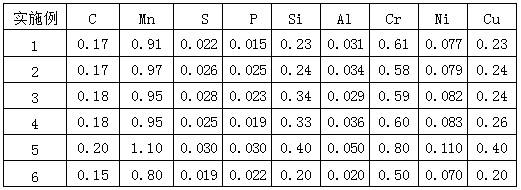

[0020] The diameter of the wear-resistant round bar product for agricultural machinery in this example is φ18 mm, and its chemical composition and mass percentage are shown in Table 1.

[0021] The production method of the wear-resistant round bar product for agricultural machinery in the present embodiment includes converter smelting, argon blowing at an argon blowing station and feeding wire, billet continuous casting process, hot rolling process and cooling bed cutting and bundling process. The specific production process steps are as follows:

[0022] (1) Converter smelting: S: 0.028%, P: 0.121% in molten iron; lime and lightly burned dolomite are used to make slag, 38kg / t of lime and 20kg / t of lightly burned dolomite are added; 2.4kg of copper plate is added with scrap steel / t, electrolytic nickel 0.8kg / t; converter end point: C: 0.043%, P: 0.012%; steel grit and aluminum are added for deoxidation and alloying during the tapping process, and silicon-manganese alloy 14kg / t...

Embodiment 2

[0029] The diameter of the wear-resistant round bar product for agricultural machinery in this embodiment is φ20mm, and its chemical composition and mass percentage are shown in Table 1.

[0030] The production method of the wear-resistant round bar product for agricultural machinery in the present embodiment includes converter smelting, argon blowing at an argon blowing station and feeding wire, billet continuous casting process, hot rolling process and cooling bed cutting and bundling process. The specific production process steps are as follows:

[0031] (1) Converter smelting: S: 0.024%, P: 0.118% in molten iron; lime and lightly burned dolomite are used to make slag, 38.6kg / t of lime and 19kg / t of lightly burned dolomite are added; kg / t, electrolytic nickel 0.9kg / t; converter end point: C: 0.049%, P: 0.015%; steel grit and aluminum are added for deoxidation and alloying during the tapping process, and silicon-manganese alloy 15kg / t, high-carbon ferrochromium 11kg / t.

[...

Embodiment 3

[0037] The diameter of the wear-resistant round bar product for agricultural machinery in this embodiment is φ22mm, and its chemical composition and mass percentage are shown in Table 1.

[0038] The production method of the wear-resistant round bar product for agricultural machinery in the present embodiment includes converter smelting, argon blowing at an argon blowing station and feeding wire, billet continuous casting process, hot rolling process and cooling bed cutting and bundling process. The specific production process steps are as follows:

[0039] (1) Converter smelting: S: 0.024%, P: 0.118% in molten iron; lime and lightly burned dolomite are used to make slag, 38.6kg / t of lime and 19kg / t of lightly burned dolomite are added; kg / t, electrolytic nickel 0.85kg / t; converter end point: C: 0.052%, P: 0.018%; steel grit and aluminum are added for deoxidation and alloying during the tapping process, and silicon-manganese alloy 15kg / t, high-carbon ferrochromium 11kg / t.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com