IN718 alloy structure optimization method based on three-dimensional wall vibration type controllable ultrasonic field device

A technology of IN718 and alloy structure, which is applied in the field of IN718 alloy structure optimization, can solve the problems of incapable of real-time feedback and control of ultrasonic parameters and effects, lack of sound field information measurement, and inability to deal with it, so as to improve smelting efficiency, avoid environmental pollution, expand Effect of heat resistance and material type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0071] In the present invention, the preparation method of the upper crucible 2 and the lower crucible 4 preferably includes: 2 O 3 The forming crucible is placed in the knotted lining, and the graphite core is placed in the Al 2 O 3 In the forming crucible, a slurry made of silica sol and sand is used to fill the gap, and the induction furnace is energized to dry the slurry and sinter it into a crucible. In the present invention, the upper crucible 2 and the lower crucible 4 are placed up and down, and the upper crucible 2 is located above. In the present invention, the sintering temperature is preferably 300°C; the sintering time is preferably 24h.

[0072] In the present invention, the charging sequence of the upper crucible 2 is preferably: Cr, Nb and Mo are charged first, and then C is added after they are completely melted; the charging sequence of the lower crucible 4 is preferably: Al, Cu, Mn, Co, Si and Ti are sequentially loaded after the Fe and Fe are completely...

Embodiment 1

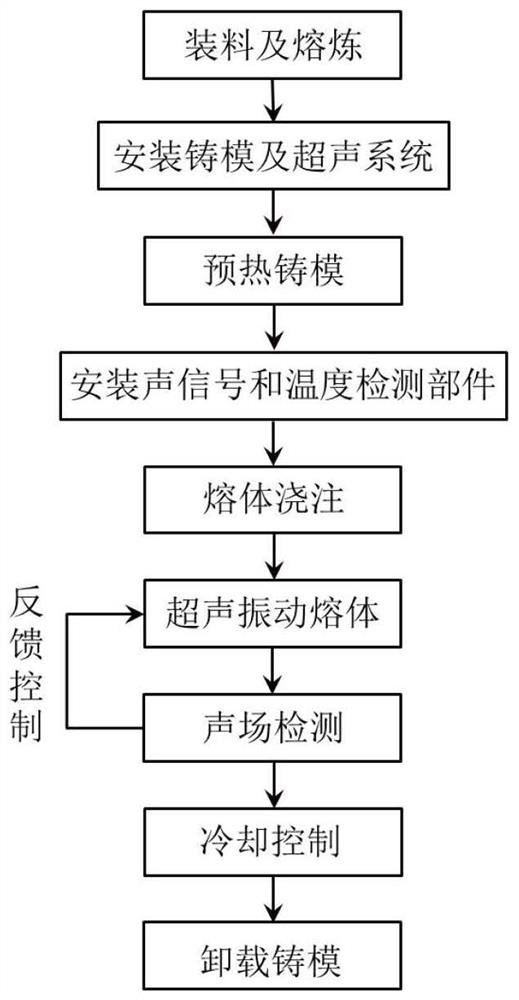

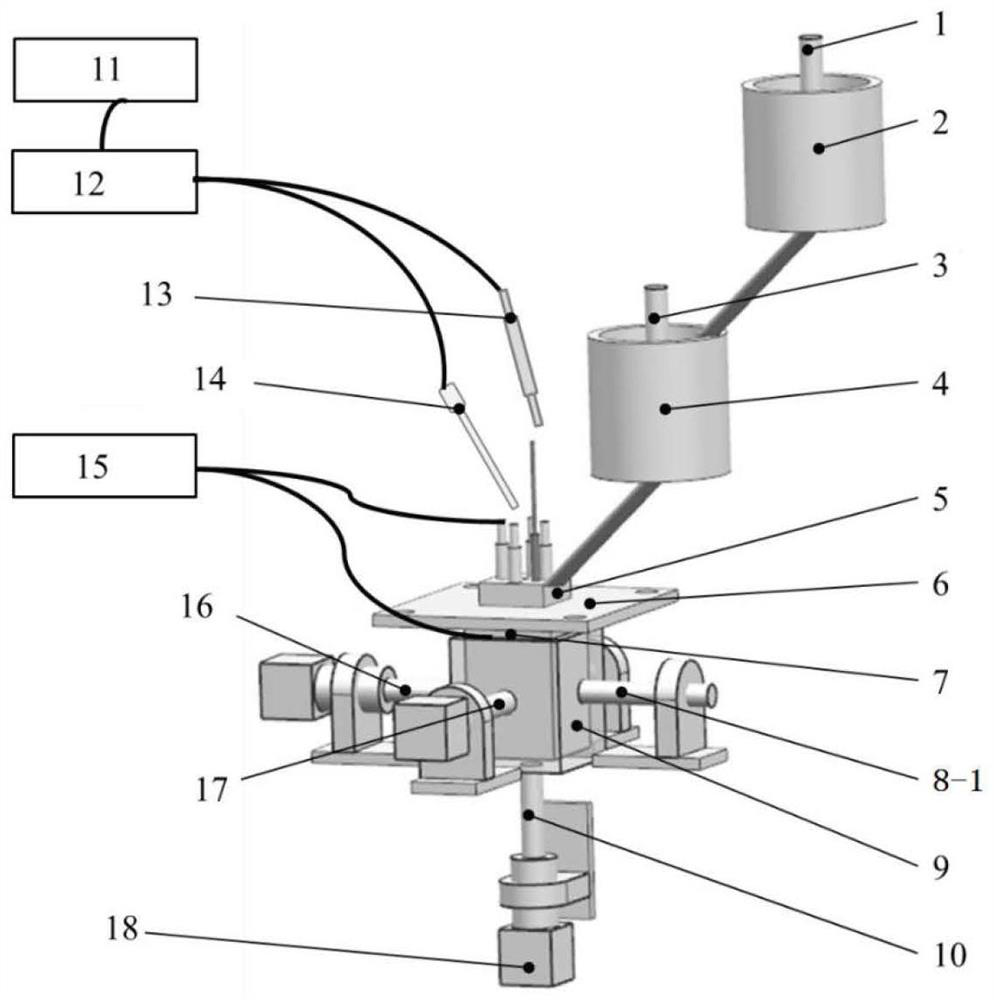

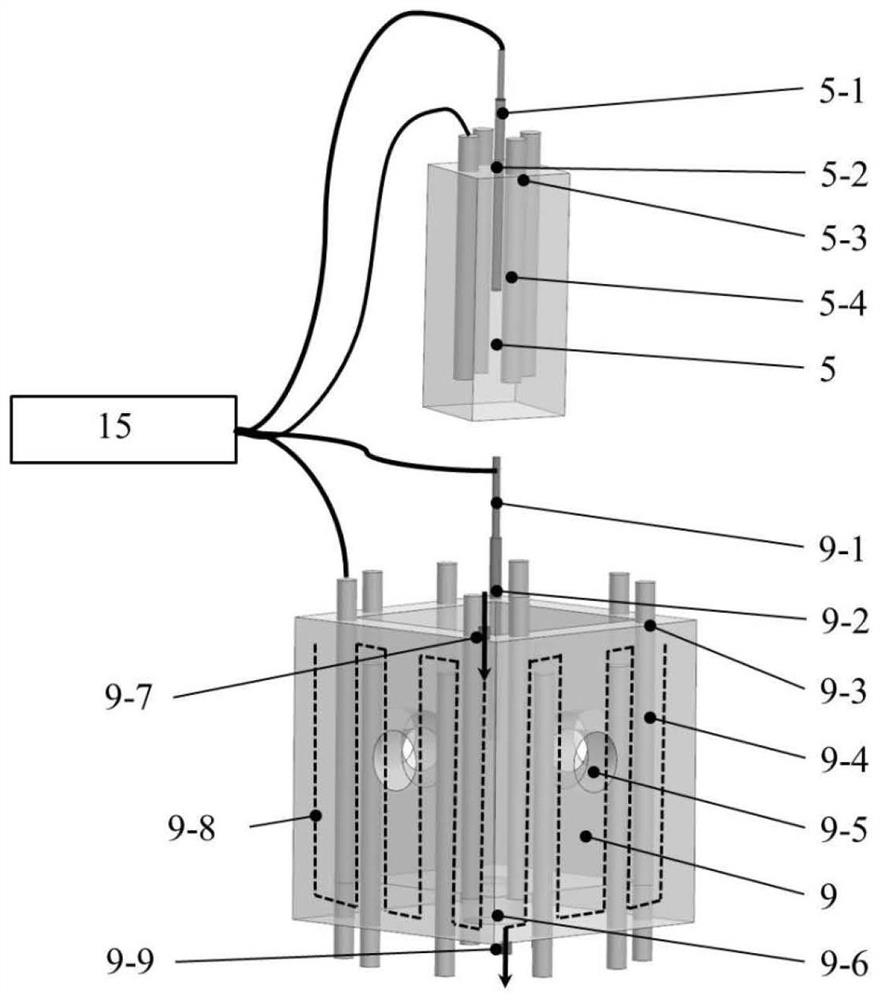

[0101] The flow chart of the microstructure optimization method of IN718 alloy based on the three-dimensional wall-vibration controllable ultrasonic field device in this embodiment is as follows: figure 1 shown. The schematic diagram of the three-dimensional wall-vibration controllable ultrasonic field device is shown in Fig. Figures 2 to 4 shown.

[0102] Step 1. First, make the upper crucible 2 and the lower crucible 4, and make the Al 2 O 3 The forming crucible is placed in the knotted lining, and the graphite core is placed in the Al 2 O 3 In the forming crucible, the gap between the silica sol and sand mixed slurry is filled, the upper crucible 2 and the lower crucible 4 are put into a resistance furnace, and the slurry is dried and sintered by baking at 300 ° C for 24 hours to obtain the upper crucible 2 and the lower crucible 4. Lower crucible 4. The upper crucible 2 and the lower crucible 4 are placed up and down, and the upper crucible 2 is located above.

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com