Sb2O3 thin film material, method for preparing Sb2O3 thin film material based on sol-gel method and application of Sb2O3 thin film material

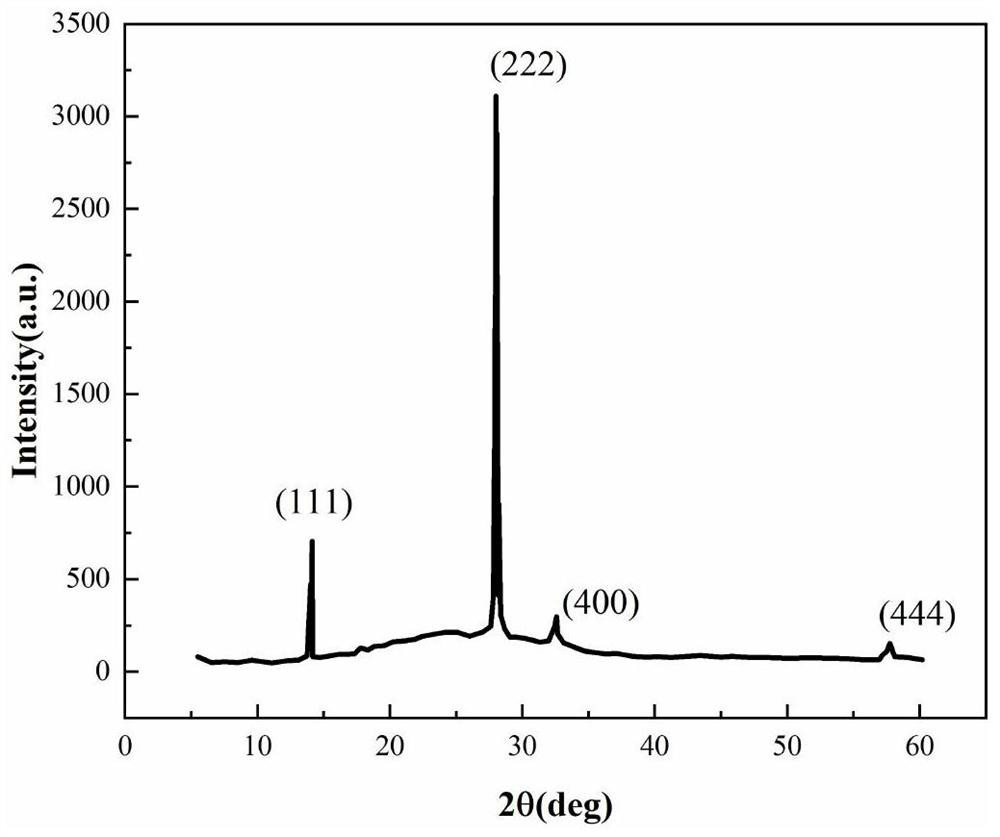

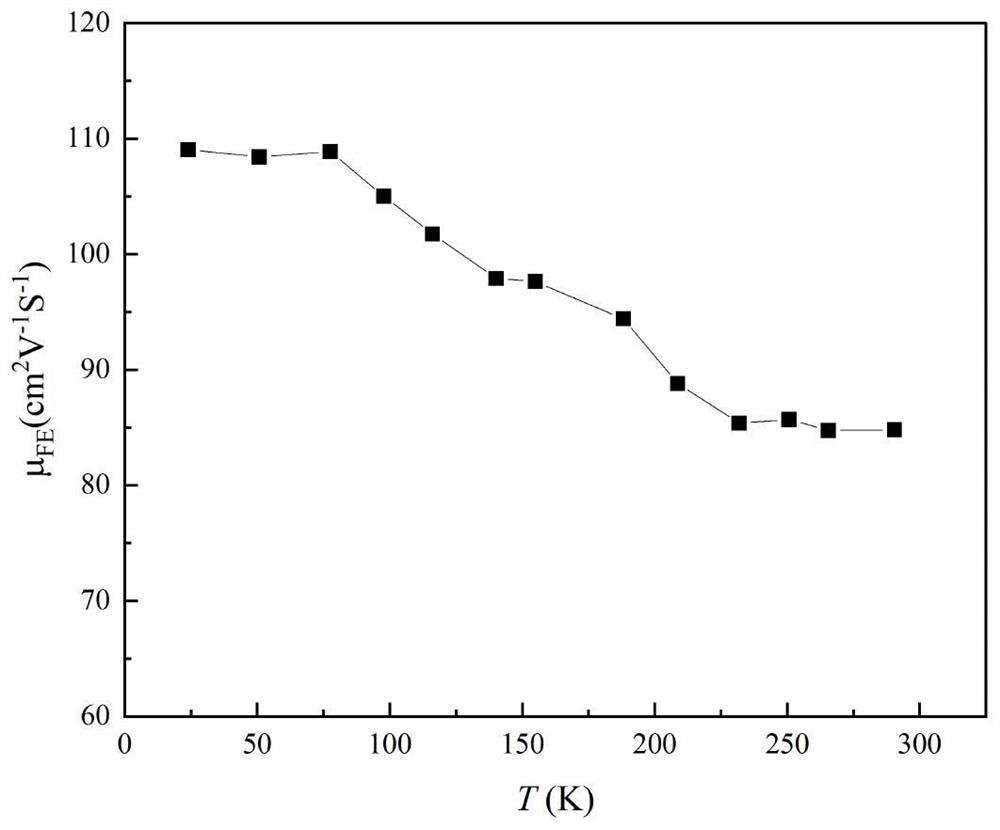

A technology of thin film material and gel method, which is applied in metal material coating process, liquid chemical plating, coating, etc. It can solve the problem that the evaporation process is not easy to control the thickness, it is not suitable for large-scale production, and the film layer is easy to fall off and other problems, to achieve the effect of convenient film thickness, good compactness and high electron mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

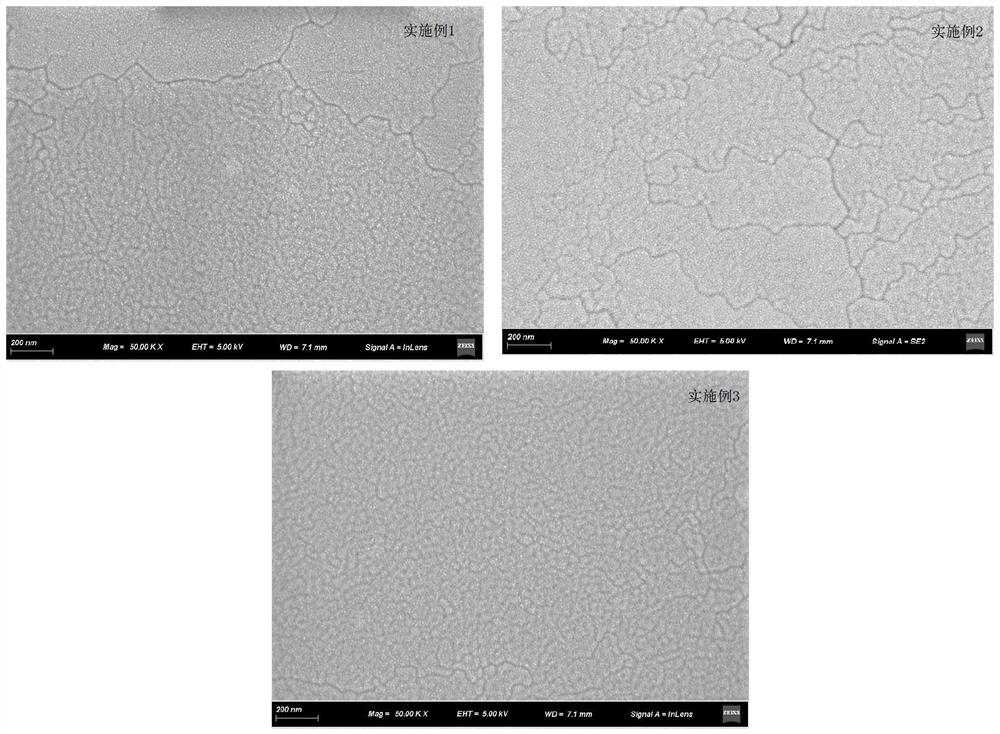

Embodiment 1

[0026] Preparation of Sb based on sol-gel method 2 O 3 A method of thin film material, the method comprising the steps of:

[0027] 1) Preparation of Sb 2 O 3 precursor solution, the C 6 H 9 O 6 The Sb raw material was dissolved in a mixed liquid at 100°C with a volume ratio of glacial acetic acid and deionized water of 1:1, mixed and stirred for 40 minutes, and left for 20 hours to obtain Sb 2 O 3 precursor solution; the Sb 2 O 3 The concentration of the precursor solution is 0.3mol / L;

[0028] 2) The Sb obtained in step 1) 2 O 3 The precursor solution was spin-coated on the substrate at 1500r / min for 30s to obtain a wet film;

[0029] 3) The wet film obtained after spin coating in step 2) was first evaporated to dryness at 90°C for 15min, then heat-treated at 400°C for 18min, taken out and cooled to room temperature to obtain a layer of incompletely crystallized Sb 2 O 3 film;

[0030] 4) Repeat steps 2) and 3) multiple times to obtain 15 layers of incompletel...

Embodiment 2

[0033] Preparation of Sb based on sol-gel method 2 O 3 A method of thin film material, the method comprising the steps of:

[0034] 1) Preparation of Sb 2 O 3 precursor solution, the N 3 O 9 The Sb raw material was dissolved in a mixed liquid at 110°C, the volume ratio of glacial acetic acid and deionized water was 1:1, mixed and stirred for 30 minutes, and left for 25 hours to obtain Sb 2 O 3 precursor solution; the Sb 2 O 3 The concentration of the precursor solution is 0.3mol / L;

[0035] 2) The Sb obtained in step 1) 2 O 3 The precursor solution was spin-coated on the substrate at 1500r / min for 35s to obtain a wet film;

[0036] 3) The wet film obtained after spin coating in step 2) was first evaporated to dryness at 95°C for 12min, then heat-treated at 450°C for 15min, taken out and cooled to room temperature to obtain a layer of incompletely crystallized Sb 2 O 3 film;

[0037] 4) Repeat steps 2) and 3) multiple times to obtain 12 layers of incompletely crysta...

Embodiment 3

[0040] Preparation of Sb based on sol-gel method 2 O 3 A method of thin film material, the method comprising the steps of:

[0041] 1) Preparation of Sb 2 O 3 precursor solution, the C 6 H 9 O 6 The Sb raw material was dissolved in a mixed liquid at 120°C with a volume ratio of glacial acetic acid and deionized water of 1:1, mixed and stirred for 20 minutes, and left for 30 hours to obtain Sb 2 O 3 precursor solution; the Sb 2 O 3 The concentration of the precursor solution is 0.3mol / L;

[0042] 2) The Sb obtained in step 1) 2 O 3 The precursor solution was spin-coated on the substrate at a speed of 1500r / min for 40s to obtain a wet film;

[0043] 3) The wet film obtained after spin coating in step 2) was first evaporated to dryness at 100°C for 10min, then heat-treated at 500°C for 12min, taken out and cooled to room temperature to obtain a layer of incompletely crystallized Sb 2 O 3 film;

[0044] 4) Repeat steps 2) and 3) multiple times to obtain 12 layers of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com