Method for manufacturing lithium ion battery cell by using nano silicon material

A lithium-ion, nano-silicon technology, applied in circuits, electrical components, battery electrodes, etc., can solve problems affecting battery cycle stability, electrode material pulverization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

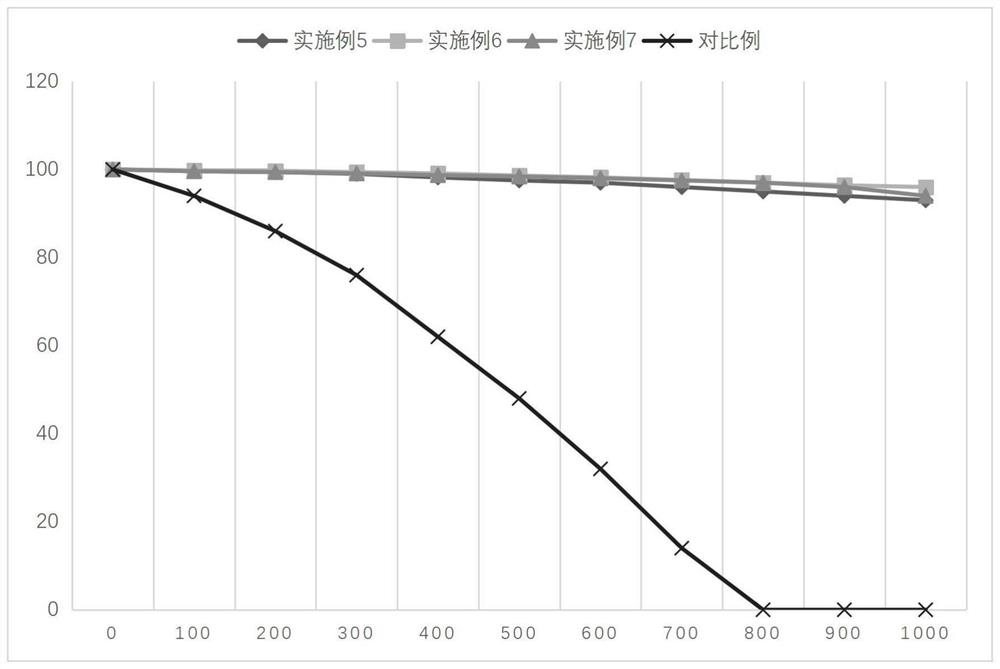

Examples

Embodiment 1

[0034] Preparation of modified carbon black:

[0035]Add 6 g of sodium methylene dinaphthalene sulfonate into 1000 mL of deionized water, stir to dissolve, add 250 g of ground conductive carbon black (passed through a 100-mesh sieve), disperse under ultrasonic conditions for 25 min, and then add 25 g of polyethylene glycol, Raise the temperature to 75°C, stir and mix for 120 minutes, filter and dry to obtain modified carbon black.

Embodiment 2

[0037] Preparation of modified carbon black:

[0038] Add 6 g of sodium methylene dinaphthalene sulfonate into 1000 mL of deionized water, stir to dissolve, then add 250 g of ground conductive carbon black (passed through a 100-mesh sieve), disperse under ultrasonic conditions for 30 min, and then add 25 g of polyethylene glycol, Raise the temperature to 80°C, stir and mix for 120 minutes, filter and dry to obtain modified carbon black.

Embodiment 3

[0040] To prepare the conductive adhesive:

[0041] S1. Add 102g of polyoxypropylene glycol and 67g of trimethylolpropane polyethylene glycol monomethyl ether into a three-necked flask equipped with a reflux condenser and a thermometer, and dehydrate in a vacuum at 105°C for 1h;

[0042] S2. Add 22g of modified carbon black prepared in Example 1 and 154g of isophorone diisocyanate, heat up to 90°C, react for 3h, cool down to 40°C, add 8g of chain extender, react at 80°C for 2h, and then again Cool down to 40°C, add 0.6g dibutyltin dilaurate, heat up to 70°C, continue the reaction for 4h, cool down to below 50°C, and discharge;

[0043] S3, adding 0.4 times the mass of water under stirring at 350 r / min to emulsify, and then adding 0.1 times the mass of 2,2-dimethylolpropionic acid for post-expansion to obtain a polyurethane emulsion;

[0044] S4. 51 g of tragacanth gum is added to 90 g of polyurethane emulsion under stirring at 350 r / min, and mixed evenly to obtain a conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com