Three-dimensional hollow WS2/C composite electrode material and preparation method and application thereof

A three-dimensional hollow, composite electrode technology, which is applied in nanotechnology for materials and surface science, battery electrodes, circuits, etc., can solve the problems of unsatisfactory sodium storage performance and poor cycle stability, and achieve easy control of reaction temperature and raw materials. The effect of low cost and short time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

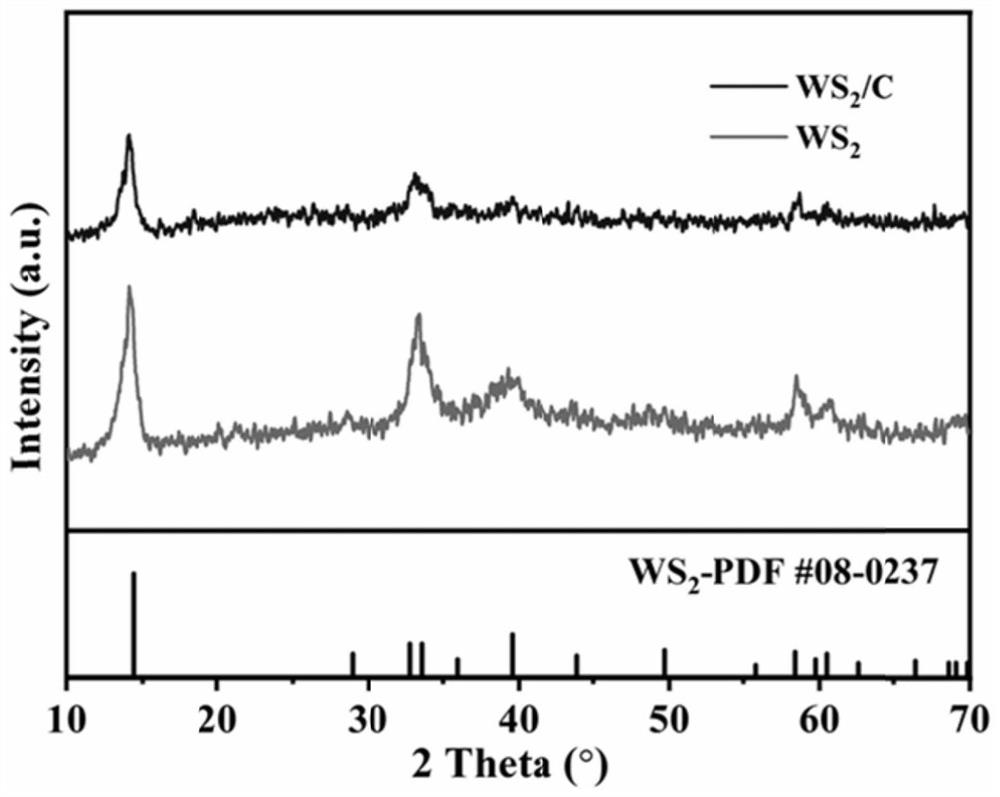

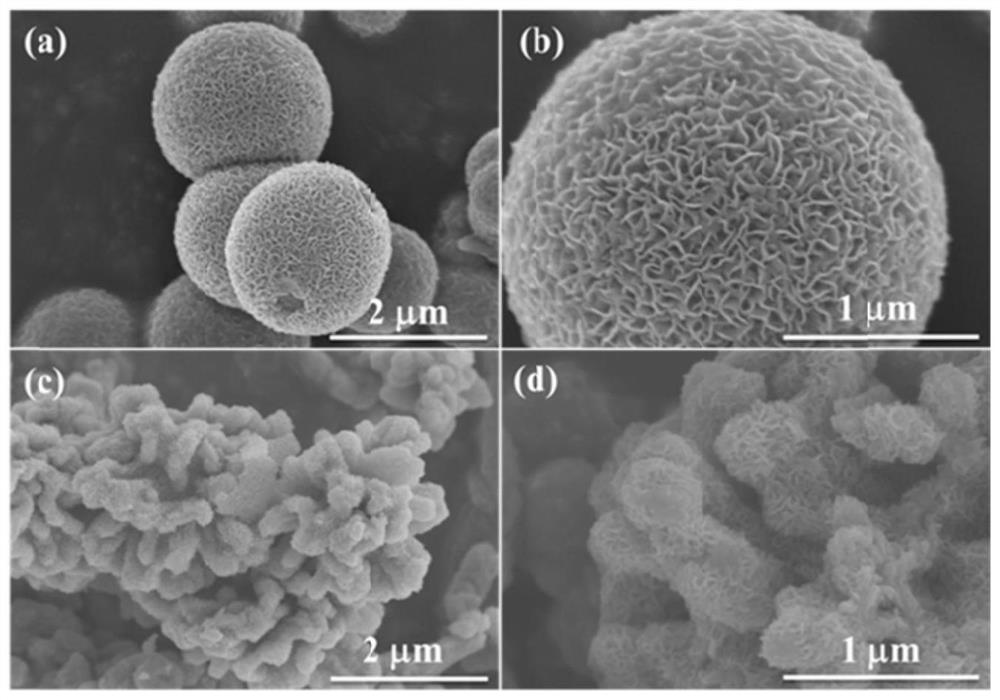

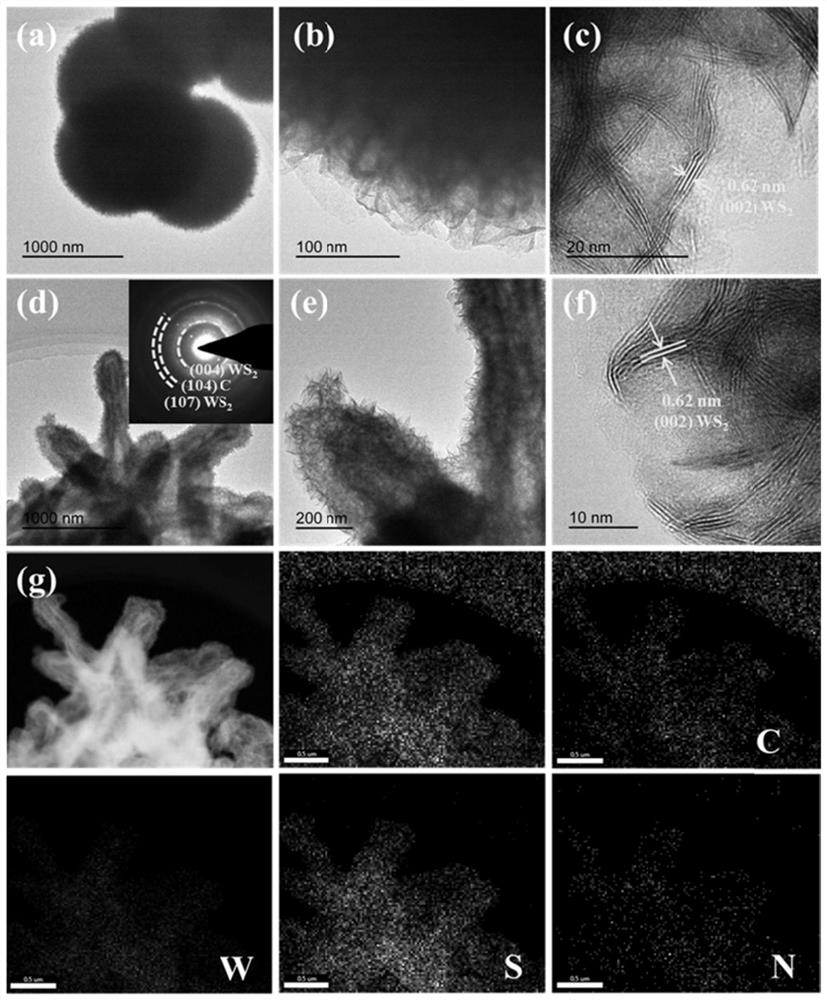

[0039] The invention discloses a three-dimensional hollow WS 2 The preparation method of / C composite electrode material includes the following steps:

[0040] Step 1: Dissolve 0.1-1g of zinc acetate in 5-30mL of ultrapure water, stir for 5-15min until dissolved to obtain a clear and transparent solution. Then, 0.1-5 mL of ammonia water was added dropwise to the above transparent solution, and after continuing to stir for 10-30 min, 5-30 mL of ultrapure water was added and stirred for 20 min to obtain a uniform and transparent solution. The solution was transferred to a 100 mL polytetrafluoroethylene-lined stainless steel autoclave, the reaction temperature was 160-220 °C, and the holding time was 12-36 h. After the reaction was completed, after cooling to room temperature, the white turbid liquid after the reaction was washed three times with ethanol and deionized water, respectively, and dried in a vacuum at 60° C. for 12 h to obtain a ZnO material.

[0041] Step 2: Take 0...

Embodiment 1

[0046] Step 1: Dissolve 0.1g of zinc acetate in 10mL of ultrapure water, stir for 5min until dissolved to obtain a clear and transparent solution. Then, 0.1 mL of ammonia water was added dropwise to the above transparent solution, and after continuing to stir for 10 min, 20 mL of ultrapure water was added and stirred for 20 min to obtain a uniform transparent solution. The solution was transferred to a 100 mL polytetrafluoroethylene-lined stainless steel autoclave, the reaction temperature was 180 °C, and the holding time was 12 h. After the reaction was completed, after cooling to room temperature, the white turbid liquid after the reaction was washed three times with ethanol and deionized water, respectively, and dried in a vacuum at 60° C. for 12 h to obtain a ZnO material.

[0047] Step 2: Add 0.1g ZnO and 0.2g 2-methylimidazole to a mixed solvent of 10mL ultrapure water and 10mL NMP, ensure that the volume ratio of the mixed solvent is 1:1, stir for 10min to make it fully...

Embodiment 2

[0051] Step 1: Dissolve 0.2g of zinc acetate in 15mL of ultrapure water, stir for 15min until dissolved to obtain a clear and transparent solution. Then, 2 mL of ammonia water was added dropwise to the above transparent solution, and after continuing to stir for 30 min, 15 mL of ultrapure water was added and stirred for 20 min to obtain a uniform transparent solution. The solution was transferred to a 100 mL polytetrafluoroethylene-lined stainless steel autoclave, the reaction temperature was 180 °C, and the holding time was 12 h. After the reaction was completed, after cooling to room temperature, the white turbid liquid after the reaction was washed three times with ethanol and deionized water, respectively, and dried in a vacuum at 60° C. for 12 h to obtain a ZnO material.

[0052] Step 2: Take 0.2g of ZnO and 0.4g of 2-methylimidazole and add it to a mixed solvent of 30 mL of ultrapure water and 30 mL of NMP to ensure that the volume ratio of the mixed solvent is 1:1. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com