Light-color insulating wear-resistant styrene butadiene rubber composition for water-cooled cable sheath and preparation method of light-color insulating wear-resistant styrene butadiene rubber composition

A technology of styrene-butadiene rubber and water-cooled cable, applied in the rubber field, can solve the problem that EPDM can not meet the performance requirements of water-cooled cable sheath, and achieve the effect of improving processing performance, high viscosity and avoiding color change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

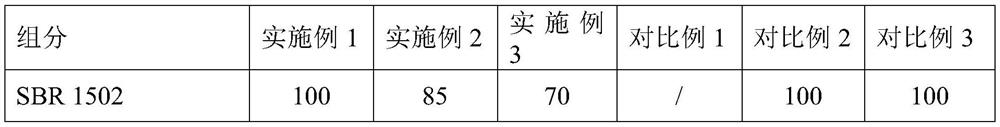

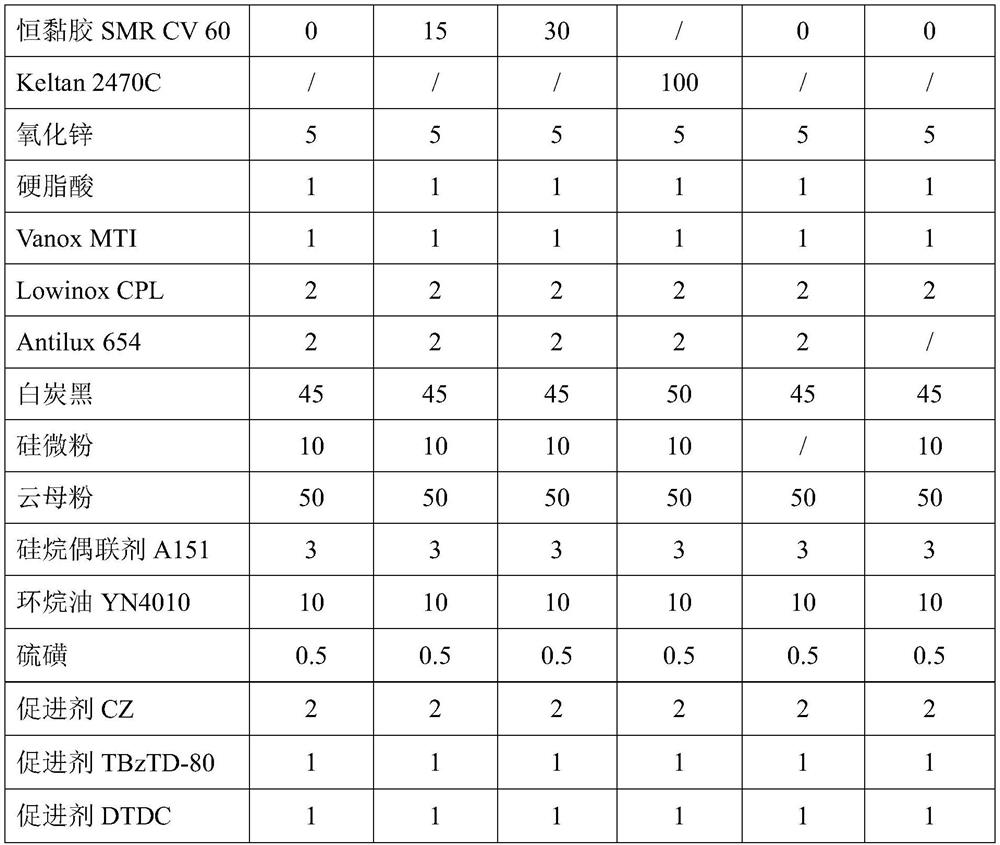

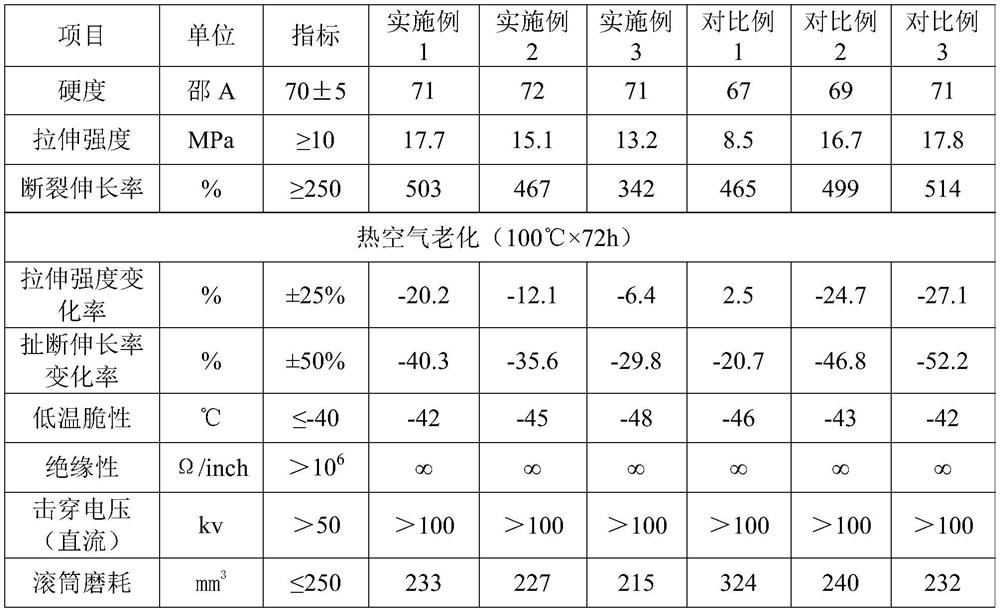

[0034] A light-colored insulating and wear-resistant styrene-butadiene rubber composition for water-cooled cable sheath, its components and parts by weight are as shown in Table 1, and prepared according to the following preparation method:

[0035] (1) The internal mixer is cooled by water, and the temperature of the internal mixer is controlled not to exceed 60 °C. First, styrene-butadiene rubber, natural rubber, antioxidant and protective wax are mixed for 1 to 2 minutes, and then zinc oxide and stearin are added. Acid, silica, silicon micropowder, silane coupling agent and naphthenic oil are mixed for 4 to 6 minutes; finally, mica powder is added and mixed for 2 to 4 minutes; the mixer is turned off and cooled, and the mixing is continued until the temperature of the mixer rises. When it reaches 140°C, remove the glue, move it to an open rubber mixing machine for thin film discharge, and cool it to room temperature (20-30°C);

[0036] (2), put the mixture obtained in step ...

Embodiment 2

[0039] A light-colored insulating and wear-resistant styrene-butadiene rubber composition for a water-cooled cable sheath, the components and parts by weight are shown in Table 1, and prepared according to the preparation method of Example 1.

Embodiment 3

[0041] A light-colored insulating and wear-resistant styrene-butadiene rubber composition for a water-cooled cable sheath, the components and parts by weight are shown in Table 1, and prepared according to the preparation method of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com