Preparation method and application of adjustable porphyrin MOFs film

A technology of porphyrin and thin film, which is applied in the field of preparation of adjustable porphyrin MOFs thin film, which can solve the problems of poor binding ability between MOFs and the substrate, difficulty in meeting the application requirements of large area and thin film of the detector, and difficulty in direct film formation, etc. , to achieve the effect of short time, simple operation and large degree of electron delocalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

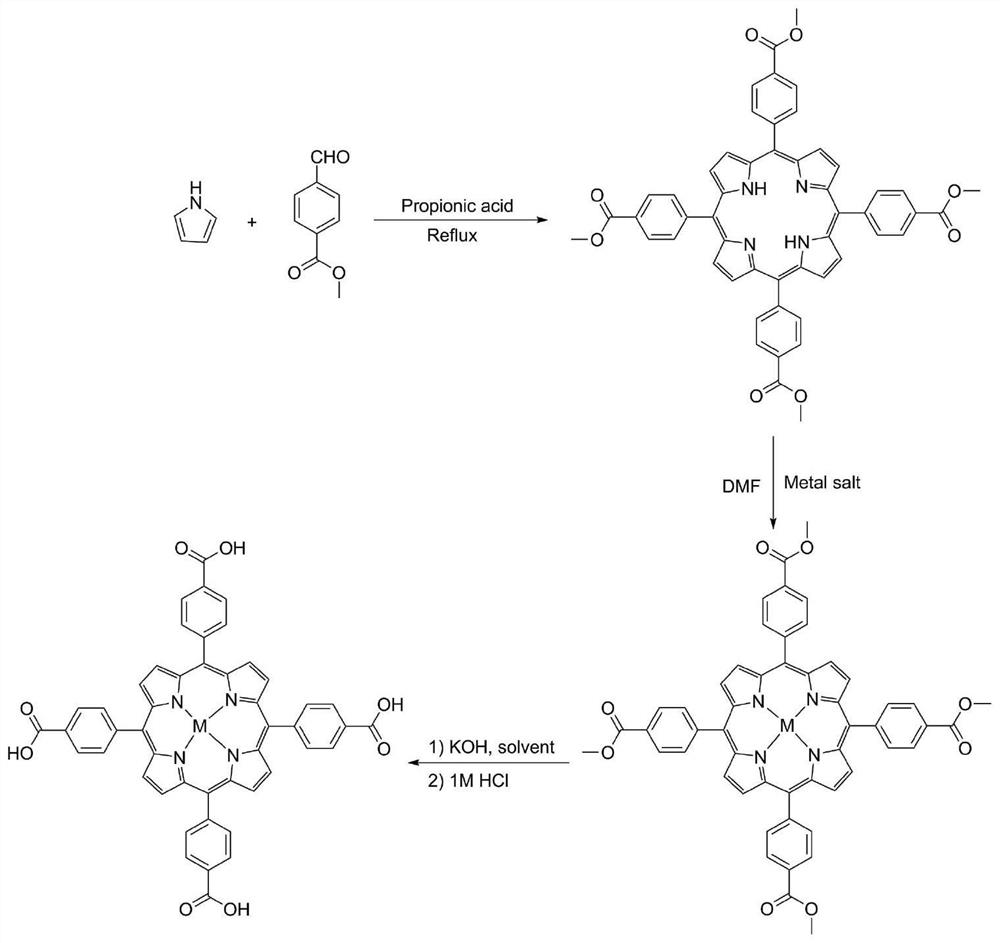

[0044] The preparation of metallated porphyrin ligands (TCPP(M), M=Zn, Mn, Fe) includes the following steps:

[0045] (1) Preparation of TPPCOOMe

[0046] Pyrrole (6.0 g, 0.086 mol) and methyl p-formylbenzoate (12 g, 0.086 mol) were heated to reflux in 100 mL propionic acid for 12 h. After the reaction mixture was cooled to room temperature, the solid was collected under reduced pressure and dried.

[0047] (2) Preparation of TPPCOOMe (M)

[0048] Take TPPCOOMe(Mn) as an example: combine TPPCOOMe (0.854g, 1.0mmol) with MnCl 2 ·6H 2 A solution of O (3.1 g, 12.8 mmol) was heated to reflux in 100 mL of DMF for 8 h, cooled to room temperature and then added with 150 mL of water. The resulting precipitate was used 50mlH 2 O filter wash twice. The resulting solid was dissolved in CHCl 3 , washed three times with water, and dried to obtain a certain amount of dark red powder.

[0049] The synthetic routes of TPPCOOMe(Zn) and TPPCOOMe(Fe) are the same as those of TPPCOOMe(Mn) ...

Embodiment 2

[0054] (1) 5,10,15,20-tetrakis(4-carboxyphenyl)porphyrin zinc (TCPP(Zn)) ligand was first prepared by the method of Example 1.

[0055] (2) Preparation of hydroxyl-functionalized growth substrates

[0056] A mixed solution of 98% sulfuric acid and 30% hydrogen peroxide (3:1 by volume) was prepared for later use, and then the oil and impurities on the surface of the silica / silicon substrate were cleaned with organic solvent and distilled water in turn. Immerse the silica / silicon substrate in the above mixed solution, heat it in a water bath at 80°C for 40 min, pour out the mixed solution after the reaction, rinse the silica / silicon substrate several times with clean water, and wash the surface of the mixture The solution was rinsed with ethanol, and finally dried with nitrogen to obtain a hydroxyl-functionalized silica / silicon substrate. Among them, concentrated sulfuric acid can also be replaced by sodium hydroxide aqueous solution.

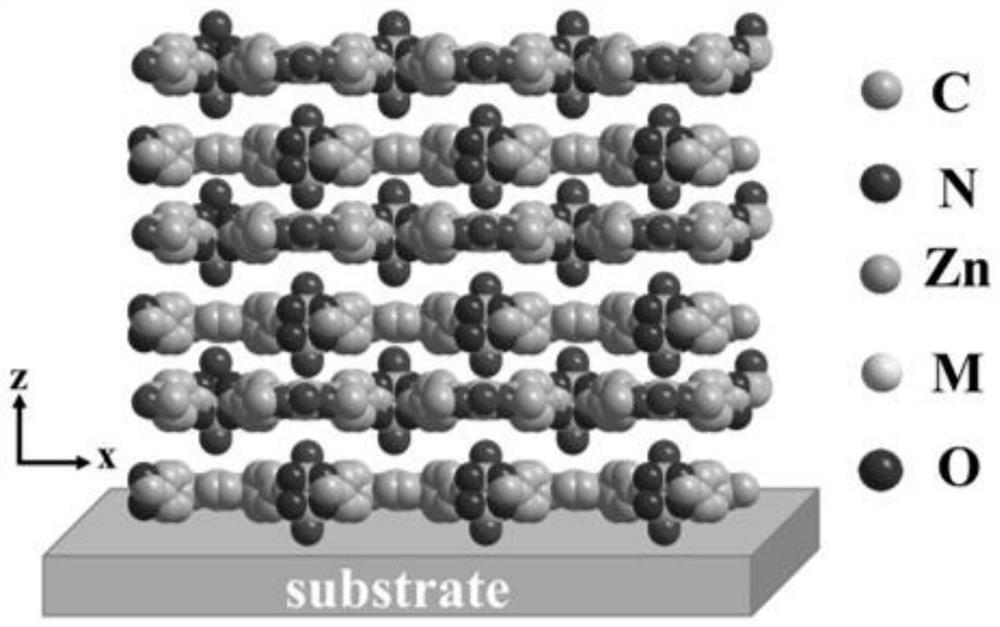

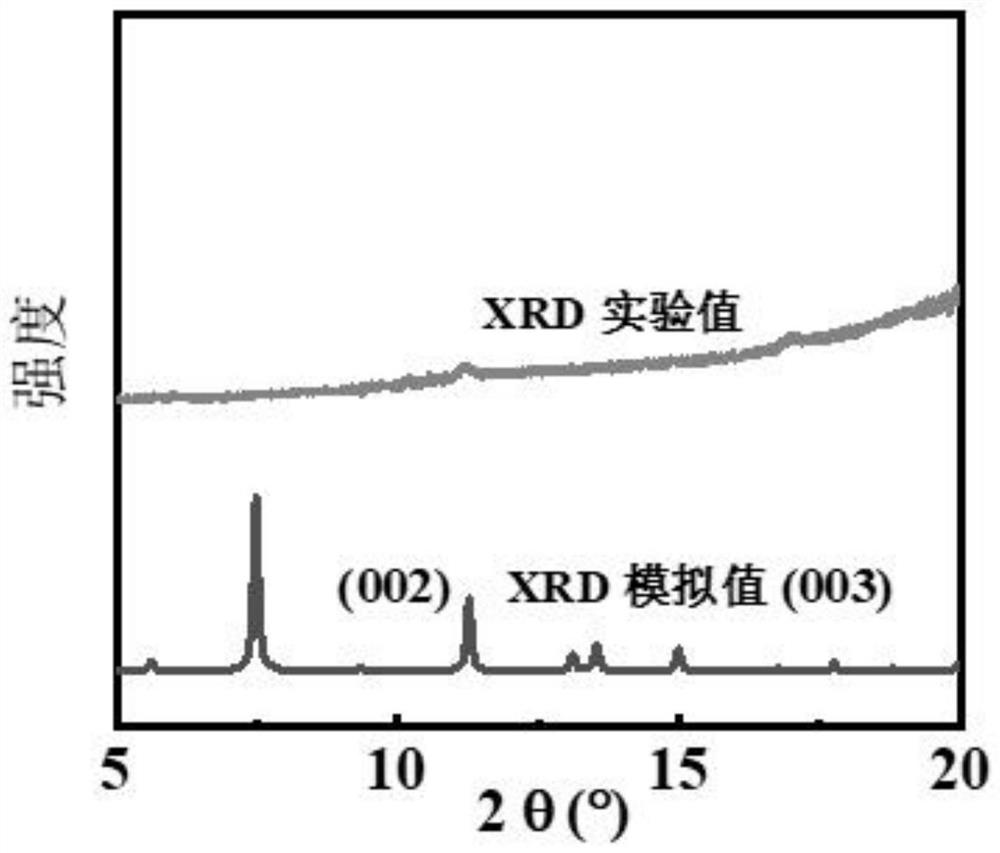

[0057] (3) Preparation of ZnTCPP(Zn) thi...

Embodiment 3

[0064] (1) 5,10,15,20-tetrakis(4-carboxyphenyl)porphyrin manganese (TCPP(Mn)) ligand was first prepared by the method of Example 1.

[0065] (2) Preparation of functionalized growth substrates

[0066] A mixed solution of 98% sulfuric acid and 30% hydrogen peroxide (3:1 by volume) was prepared for later use, and then the oil and impurities on the surface of the silica / silicon substrate were cleaned with organic solvent and distilled water in turn. Immerse the silica / silicon substrate in the above mixed solution, heat it in a water bath at 80°C for 40 min, pour out the mixed solution after the reaction, rinse the silica / silicon substrate several times with clean water, and wash the surface of the mixture solution, rinsed with ethanol, and finally dried with nitrogen to obtain hydroxyl-functionalized silica / silicon substrates. Concentrated sulfuric acid can also be replaced with aqueous sodium hydroxide solution. The hydroxyl-functionalized silica / silicon substrate can be furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com