Preparation method and application of iron nickel phosphide nanosheet forming capacitor material

A technology of nanosheets and iron phosphide, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, phosphides, etc., can solve the problems of poor rate performance and cycle performance, and limited specific capacitance value, and achieve electrochemical performance Excellent, not easy to fall off, and the effect of high-efficiency electronic paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

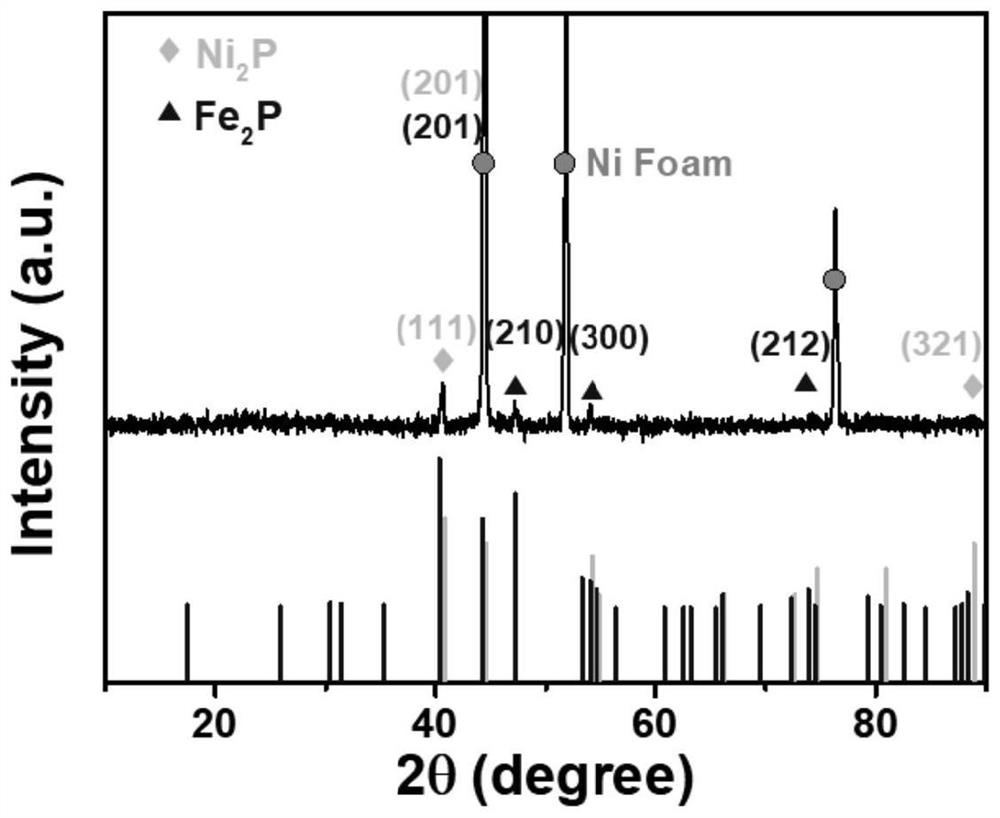

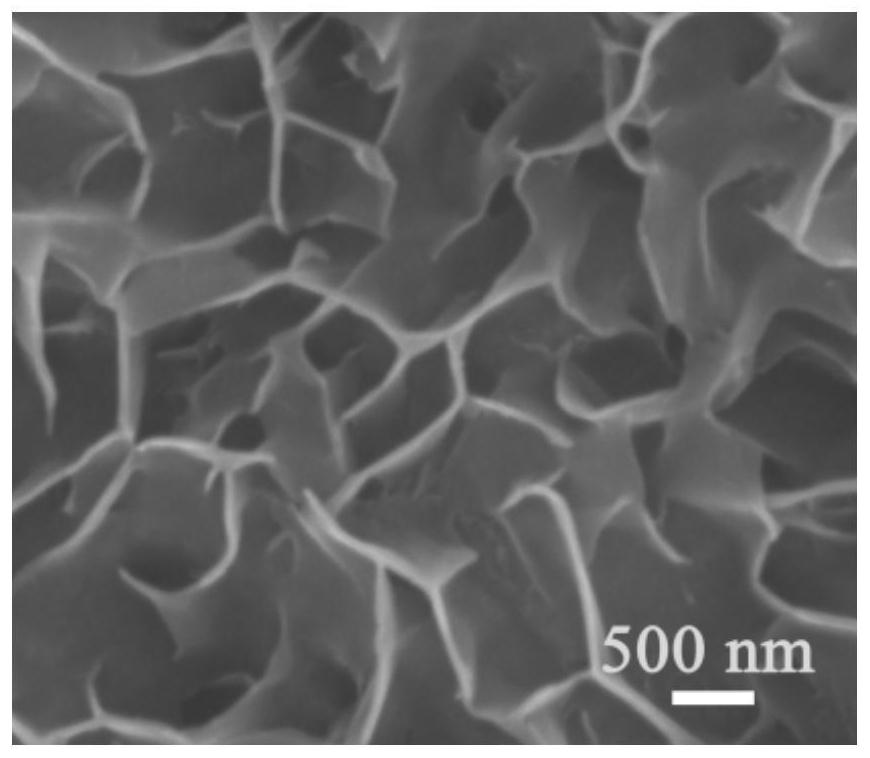

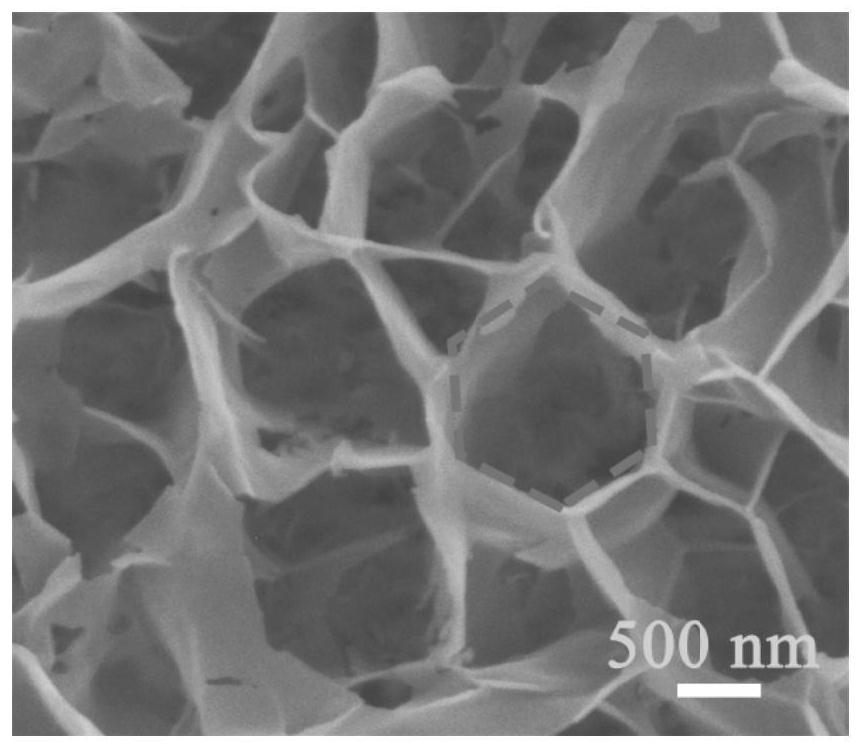

[0031] In this embodiment, the preparation method of the iron-nickel phosphide nanosheets constituting the capacitor material is as follows:

[0032] Step (1) Cut out 3.8×5.2cm 2 The nickel foam was ultrasonically cleaned with dilute hydrochloric acid, alcohol, and deionized water for 15 minutes.

[0033] Step (2) respectively adding ferric chloride and sodium chloride in a molar ratio of 1:1 to 60 mL of deionized water, and magnetically stirring for 30 minutes to dissolve.

[0034] Step (3) Transfer the nickel foam cleaned in step (1) and the mixed solution prepared in step (2) to a 100 mL hydrothermal reactor, and react at 120° C. for 10 hours.

[0035] Step (4) After the reaction is completed, after cooling to room temperature, the nickel foam loaded with the iron-nickel double metal hydroxide is taken out, and washed with deionized water by shaking. Dry at 80°C for 10h.

[0036] Step (5) The dried nickel foam loaded with iron-nickel double metal hydroxide is placed in a...

Embodiment 2

[0039] In this embodiment, the application of the iron-nickel phosphide nanosheets constituting the capacitor material is as follows:

[0040] In step (1), choose molar concentration to be 3mol L -1 The potassium hydroxide aqueous solution was used as the electrolyte, the platinum electrode was used as the counter electrode, and the Ag / AgCl was used as the reference electrode to test the cyclic voltammetry curve of the iron-nickel double metal hydroxide supercapacitor electrode material.

[0041] In step (2), choose molar concentration to be 3mol L -1 The potassium hydroxide aqueous solution was used as the electrolyte, the platinum electrode was used as the counter electrode, and the Ag / AgCl was used as the reference electrode.

[0042] In step (3), the voltage range of the cyclic voltammetry curve test in steps (1) and (2) is 0-0.45V, and the scanning speed range is 1-100mVs -1 ; The voltage range of the charge-discharge test described in step (2) is 0~0.4V, and the curren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com