Preparation method of antireflection coating liquid

一种镀膜液、减反射的技术,应用在减反射镀膜液的制备领域,能够解决未涉及耐脏污性及耐候性能、制备过程繁冗、反应时间长等问题,达到耐脏污及耐候性能优异、制备过程简单、反应时间短的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of the antireflection coating solution of the present embodiment includes the following steps:

[0041] 1) Preparation of silane polymer

[0042] By weight, the silane polymer in this embodiment includes the following raw material components:

[0043]

[0044] The ethyl orthosilicate, methyltriethoxysilane, water, hydrochloric acid, and isopropanol in the above formula were added to the reaction kettle in turn while stirring, and the water bath was heated to 60 ° C, and the reaction was kept for 4 hours. Silane polymer, cooled and discharged for use.

[0045] 2) Preparation of nanoparticles

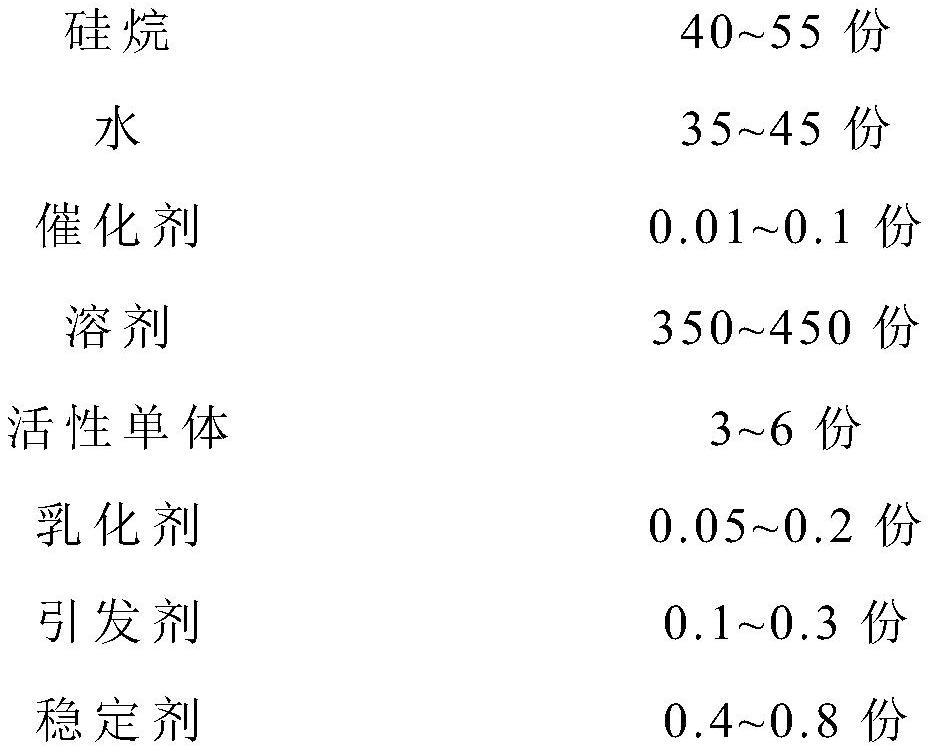

[0046] By weight, the nanoparticles in this embodiment include the following raw material components:

[0047]

[0048] Add methacrylic acid, sodium lauryl sulfate, potassium persulfate, and water into the reaction kettle in turn, stir at high speed to fully emulsify the raw materials, heat the water bath to 75 °C, and react for 2 hours. After the re...

Embodiment 2

[0053] The preparation method of the antireflection coating solution of the present embodiment includes the following steps:

[0054] 1) Preparation of silane polymer

[0055] By weight, the silane polymer in this embodiment includes the following raw material components:

[0056]

[0057] Ethyl orthosilicate, phenyltrimethoxysilane, dimethyldiethoxysilane, water, acetic acid, and isopropanol in the above formula were added to the reaction kettle in turn while stirring, and the water bath was heated to 50° C. The reaction was carried out for 5h, and after the reaction was completed, a silane polymer was obtained, and the material was cooled and discharged for use.

[0058] 2) Preparation of nanoparticles

[0059] By weight, the nanoparticles in this embodiment include the following raw material components:

[0060]

[0061] Add butyl methacrylate, styrene, dodecylamine polyoxyethylene ether, ammonium persulfate, and water into the reaction kettle in turn, stir at a hi...

Embodiment 3

[0085] The anti-reflection coating solution is coated on the surface of the ultra-white patterned glass by spraying, roller coating, pulling, roller coating, and spin coating. Anti-reflection coated glass is obtained by tempering at 750°C for 2-5 minutes. The samples were tested for anti-reflection, dirt resistance and weather resistance, and the results were as follows:

[0086] Table 1 Test results

[0087]

[0088] The test results in Table 1 show that the photovoltaic glass obtained by using the antireflection coating solution prepared by the method of the present invention has higher light transmittance (over 2.30% antireflection), excellent dirt resistance and weather resistance.

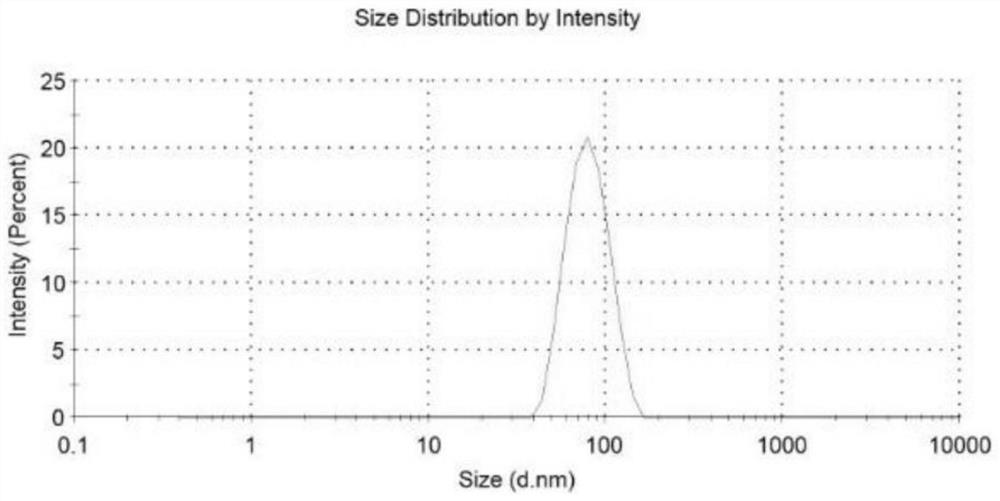

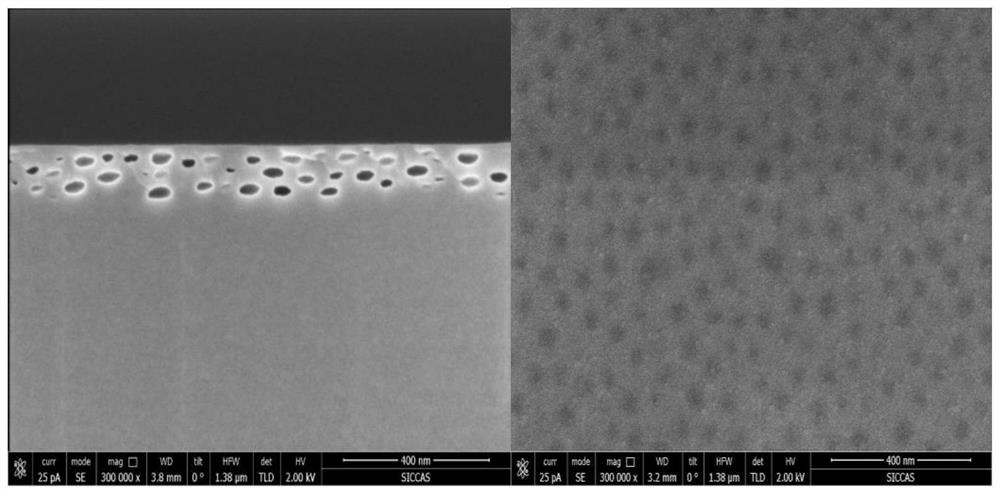

[0089] The antireflection coating solution with high antireflection and dirt resistance provided by the invention has high antireflection, excellent comprehensive performance, simple preparation process, short reaction time and high production efficiency. like figure 2 As shown, the pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com