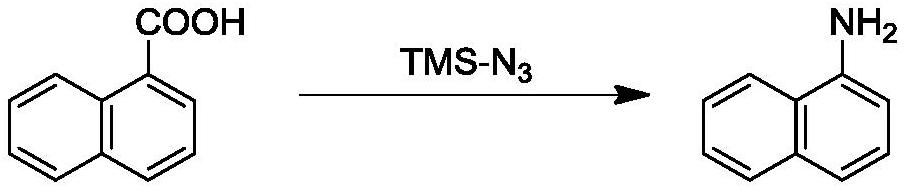

Method for rapidly preparing 1-naphthylamine based on microchannel continuous flow technology

A technology of microchannel and microchannel reactor, which is applied in the preparation of amino compounds, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of limited feasibility of industrial amplification, achieve the suppression of amplification effect and ensure product quality , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

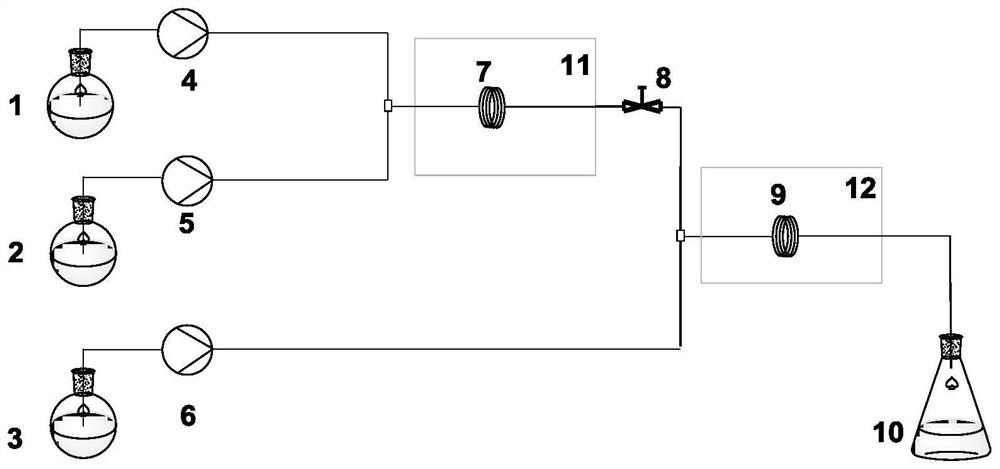

[0035] Example 1: as figure 1As shown, the trifluoromethanesulfonic acid solution of 1-naphthoic acid with a concentration of 1.1 mol / L is loaded into the storage tank 1, and the chloroform solution of azidotrimethylsilane with a concentration of 0.6 mol / L is loaded into the storage tank In 2, the methanol is loaded into the storage tank 3, and the trifluoromethanesulfonic acid solution of 1-naphthoic acid and the chloroform solution of azidotrimethylsilane are pumped into the first metering pump 4 and the second metering pump 5 respectively. The Schmidt amination reaction is carried out in a microchannel reactor 7, the molar equivalent ratio of 1-naphthoic acid and azidotrimethylsilane is 1:1.2, and the reaction temperature of the first microchannel reactor is the first constant temperature bath 11 Controlled 100°C, the set pressure of the back pressure valve is 2.0MPa, the design residence time of the first microchannel reactor is 15min, and the actual residence time is 12mi...

Embodiment 2

[0036] Example 2: The specific reaction process was similar to that of Example 1, and post-processing processes such as column chromatography were not performed. The set pressure of the back pressure valve was changed to 2.3MPa; the design residence time of the first microchannel reactor was changed to 10min; the design residence time of the second microchannel reactor was changed to 3.3min, and the purity of the product in the reaction solution was 81.0 %.

Embodiment 3

[0037] Example 3: The specific reaction process was similar to that of Example 1, and post-processing processes such as column chromatography were not performed. Change the temperature of the first constant temperature bath for Schmidt amination reaction to 90°C; change the design residence time of the first microchannel reactor to 5min; change the design residence time of the second microchannel reactor to 3min to obtain the reaction The purity of the product in the liquid was 72.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com