Hazardous waste salt pyrolysis system and pyrolysis process thereof

A pyrolysis and process technology, applied in lighting and heating equipment, combustion types, incinerators, etc., can solve problems such as short service life of electromagnetic induction components, large connection size, safety or environmental accidents, etc., to ensure the sealing performance of equipment, Improve the sealing performance of equipment and ensure the effect of no oxygen leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

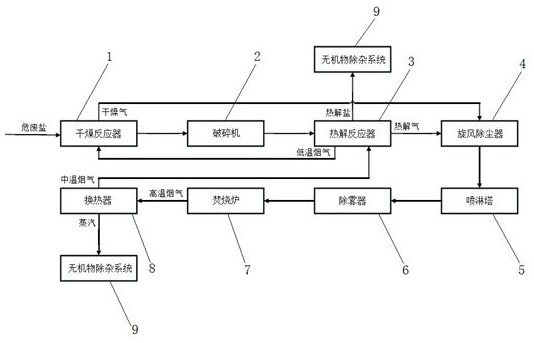

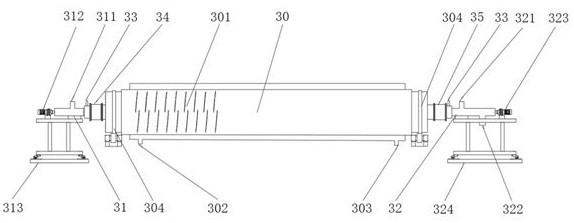

[0037] see figure 1, a hazardous waste salt pyrolysis system, used to remove organic impurities in hazardous waste salt, so as to realize the recycling and utilization of hazardous waste salt. The pyrolysis system includes a pretreatment device, a pyrolysis reactor 3 and a gas purification and recovery device. The pretreatment device includes a drying reactor 1 and a crusher 2. The drying reactor 1 includes a solid inlet, a solid outlet, a gas inlet and a gas outlet. The pyrolysis reactor 3 includes a solids inlet, a pyrolysis gas outlet 321 , a pyrolysis salt outlet 322 , a heated flue gas inlet 303 and a heated flue gas outlet 302 . The gas purification and recovery device includes a cyclone 4, a spray tower 5, a mist eliminator 6, an incinerator 7 and a heat exchanger 8. The cyclone 4 includes a first inlet and a second inlet, and the heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com