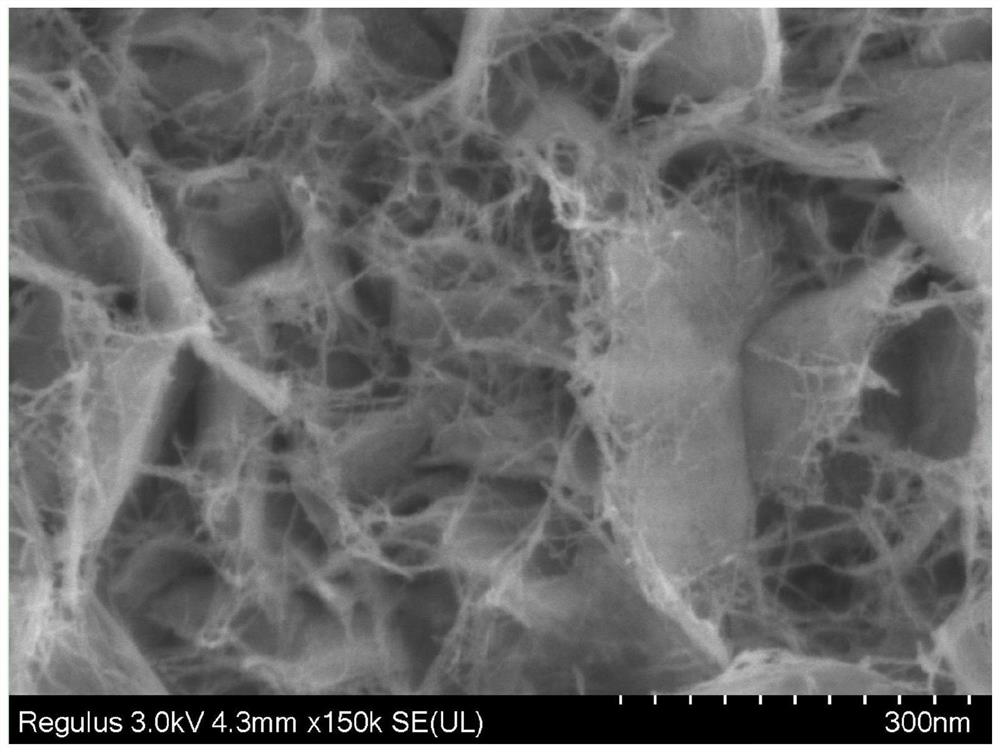

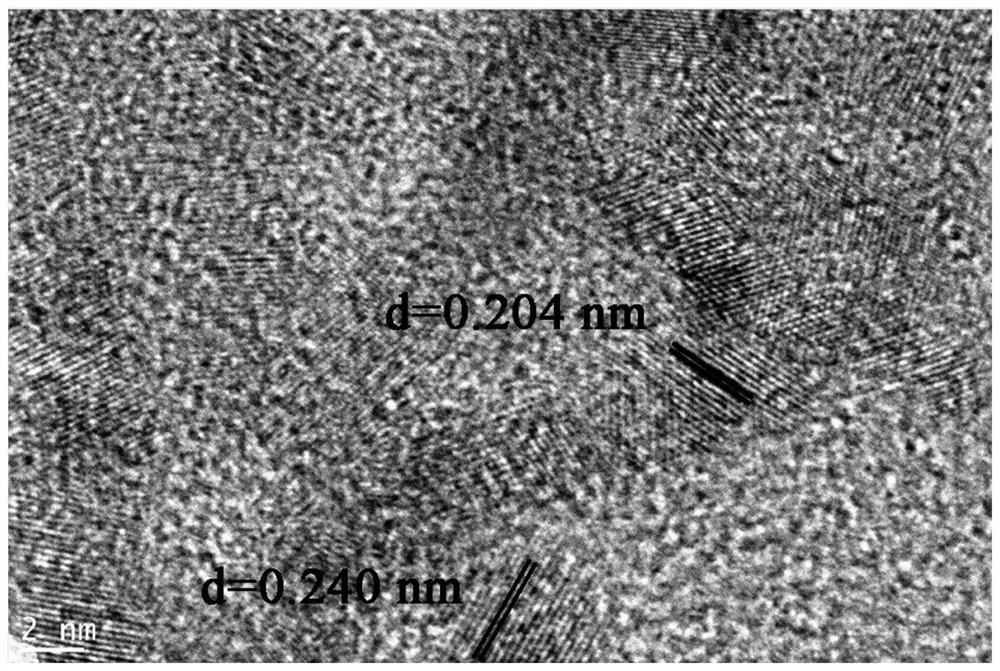

Nickel oxide nano hierarchical structure electrochromic capacitance material and preparation method thereof

A technology of nickel oxide nanosheets and hierarchical structure, which is applied in the direction of color-changing fluorescent materials, chemical instruments and methods, nano optics, etc., can solve the problems of unfavorable industrial production, time-consuming and labor-intensive, and many control factors, so as to improve coloring efficiency and enhance Effect of chemical adsorption and large reaction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

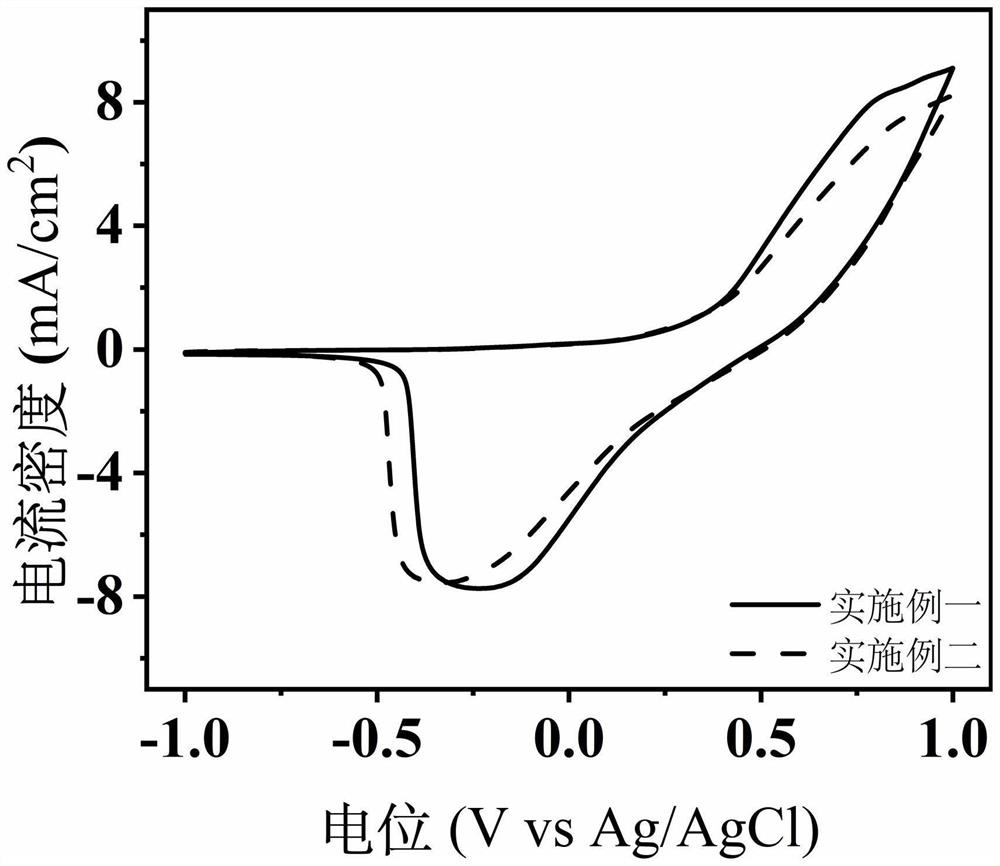

Embodiment 1

[0043] A method for preparing a nickel oxide nanoscale hierarchical structure electrochromic capacitor material, the specific steps are as follows:

[0044] (1) The FTO conductive glass was placed in a beaker containing acetone, ethanol and deionized water in turn and ultrasonicated for 10min respectively, then placed on the filter paper and baked with an infrared lamp, and then placed in a UV light cleaning machine for 30min. .

[0045] (2) Preparation of seed layer: 1.5 mmol of nickel acetate tetrahydrate was placed in 100 mL of ethanol for magnetic stirring for 10 min, and the stirring speed was 800 r / min, and then the nickel acetate solution was placed in an ultrasonicator for ultrasonic dispersion for 10 min. Then, into the prepared 15mol / L nickel acetate ethanol solution, add the FTO conductive glass treated in step (1), heat up to 60°, and take a water bath for 45min. Then, it was washed with deionized water and dried at a drying temperature of 60 °C and a drying time ...

Embodiment 2

[0051] A method for preparing a nickel oxide nanoscale hierarchical structure electrochromic capacitor material, the specific steps are as follows:

[0052] (1) The FTO conductive glass was placed in a beaker containing acetone, ethanol and deionized water in turn and ultrasonicated for 10min respectively, then placed on the filter paper and baked with an infrared lamp, and then placed in a UV light cleaning machine for 30min. .

[0053] (2) Preparation of seed layer: 1.5 mmol of nickel acetate tetrahydrate was placed in 100 mL of ethanol for magnetic stirring for 10 min, and the stirring speed was 800 r / min, and then the nickel acetate solution was placed in an ultrasonicator for ultrasonic dispersion for 10 min. Then, the FTO conductive glass treated in step (1) was added to the prepared 15 mol / L nickel acetate ethanol solution, the temperature was raised to 60° C., and the water bath was carried out for 45 min. Then, it was washed with deionized water and dried at a drying...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com