Amorphous Ga2O3 solar-blind ultraviolet detector based on MgO passivation and preparation method thereof

An ultraviolet detector, amorphous technology, applied in the field of ultraviolet detection, can solve the problems of limited substrate selection, slow reaction time, thermal budget increase, etc., achieve stable detection performance, increase wavelength selectivity, improve response time and response degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

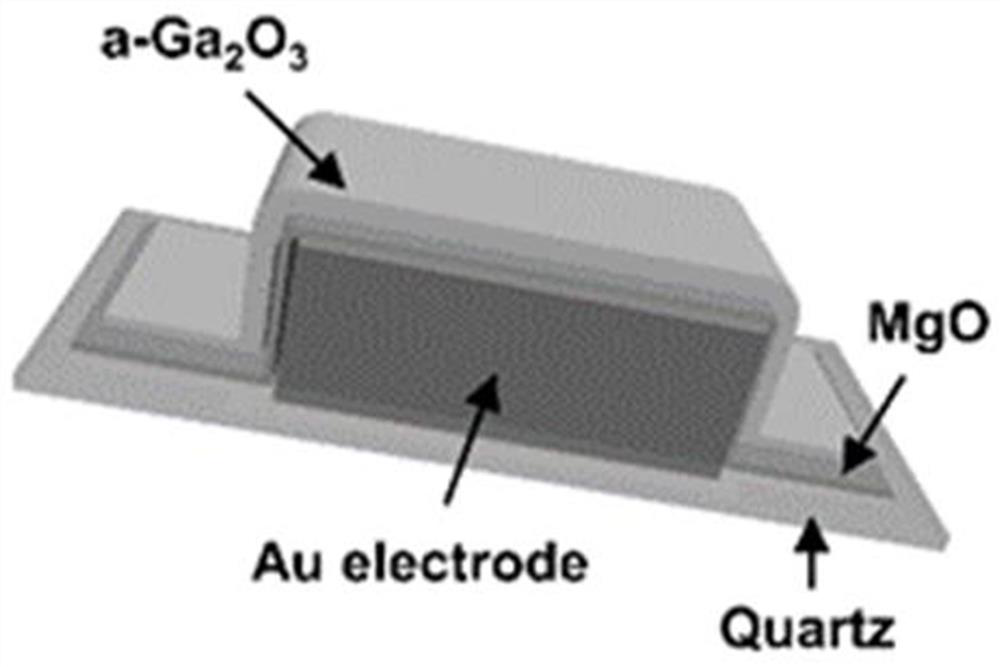

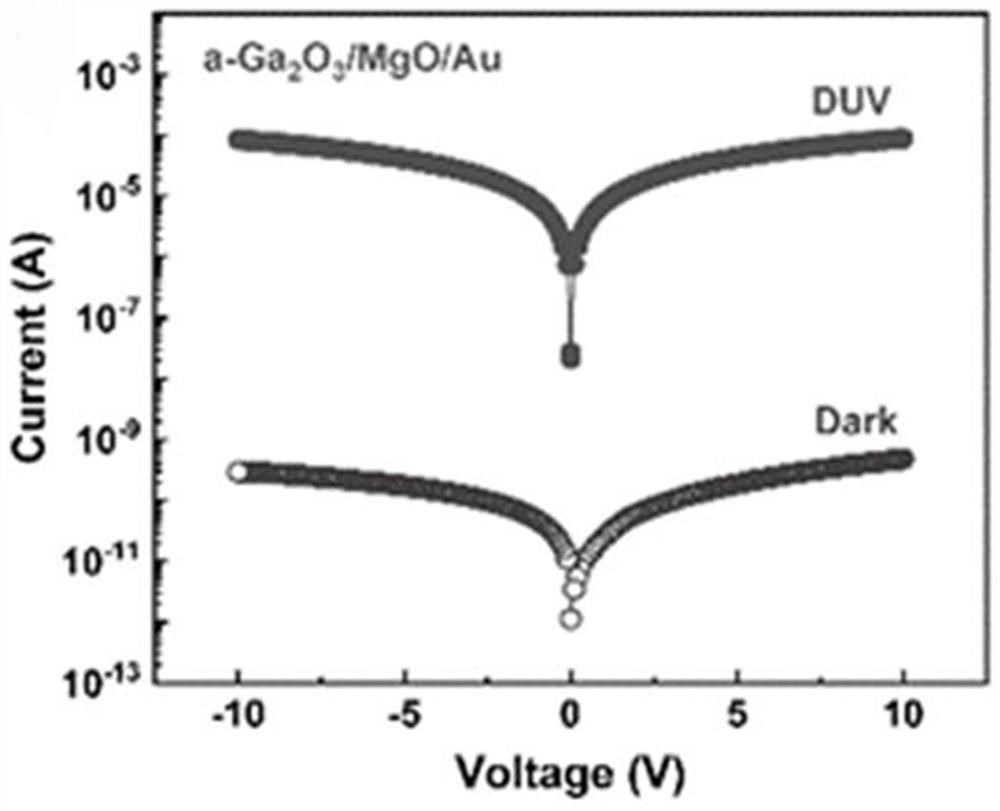

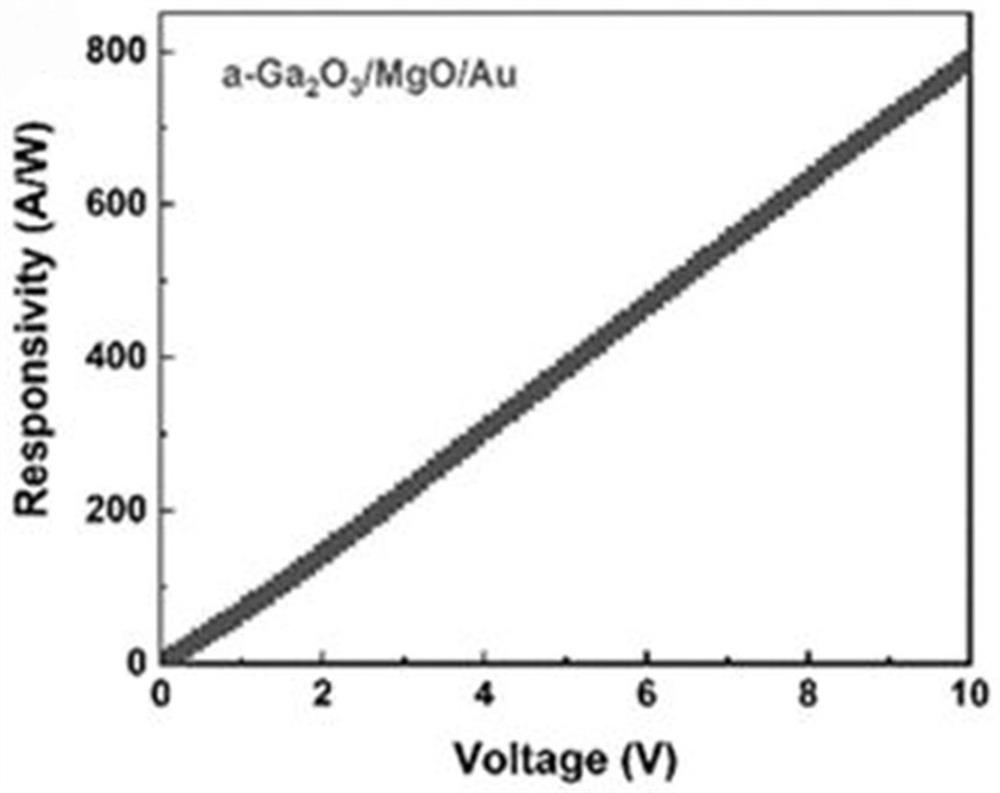

[0074] Amorphous Ga based on MgO passivation 2 O 3 A solar-blind UV detector, a plasma-enhanced atomic layer deposition (PE-ALD) based amorphous a-Ga 2 O 3 A solar-blind photodetector with high responsivity and fast response time of thin film, through preparation of substrate technology, ultraviolet lithography technology (preferably using contact ultraviolet lithography machine) processing technology and atomic layer deposition equipment (preferably using Picsun 200R plasma volume-enhanced atomic layer deposition equipment) treatment process; and when the atomic layer deposition equipment is processed, (cyclopentadienyl) magnesium (MgCp 2 ), triethylgallium (TEG) and oxygen as Mg source, Ga source and O source, that is, in the preparation, (cyclopentadienyl)magnesium, TEG and oxygen were used as Ga (gallium) source and O ( The reaction precursor of the oxygen) source is sent into the reaction chamber of the atomic layer deposition equipment, and the resulting amorphous Ga ...

Embodiment 2

[0080] This embodiment is further optimized on the basis of the above-mentioned embodiment, and the same parts as the above-mentioned technical solutions will not be repeated here. Further, in order to better realize the amorphous Ga based on MgO passivation described in the present invention 2 O 3 The solar-blind ultraviolet detector, in particular, adopts the following setting method: the process for preparing the substrate includes the following steps:

[0081] 1.1) Cut a large piece of raw material as a substrate into 1×1cm 2 size, forming a substrate;

[0082] 1.2) load the cut substrate into the quartz tube, add soapy water for ultrasonic cleaning 15-30min (preferably 15min);

[0083] 1.3) rinse the soapy water in the quartz tube with deionized water, then use deionized water ultrasonic cleaning two-four times (preferably 2 times), single 15-30min (preferably 15min);

[0084] 1.4) After step 1.3), use acetone and ethanol to carry out ultrasonic cleaning respectively f...

Embodiment 3

[0087] This embodiment is further optimized on the basis of any of the above-mentioned embodiments, and the same parts as the previous technical solutions will not be repeated here, and further to better realize the amorphous Ga based on MgO passivation described in the present invention 2 O 3 The solar-blind ultraviolet detector especially adopts the following setting method: the ultraviolet lithography technology processing process includes the following steps:

[0088] 2.1) Pretreatment, place the substrate obtained in step 1) on a heating table and heat it at 110-120°C (preferably 110°C) for 5-10min (preferably 5min) to remove the residual water vapor on the surface of the substrate to prevent influence Adhesion between photoresist and substrate;

[0089] 2.2) Glue homogenization, in the process of glue homogenization, the rotation speed is completed in two steps, first at 500~600r / min (preferably 500r / min), lasting 5~7s (preferably 5s) low speed rotation, and then rising...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com